Overhead floor heating mounting structure of fabricated ground

An installation structure and assembly technology, applied in the direction of floor, heating method, building structure, etc., can solve the problems of prolonged construction period, long construction period, dust pollution, etc., and achieve the effect of improving overall bearing performance, simple installation and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

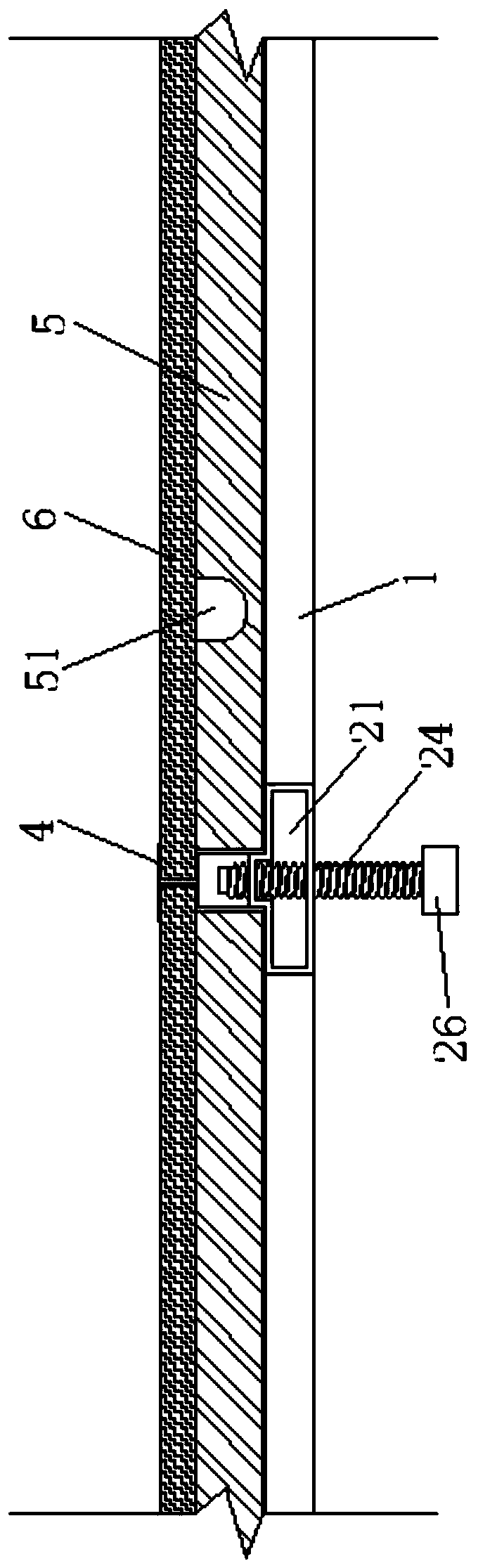

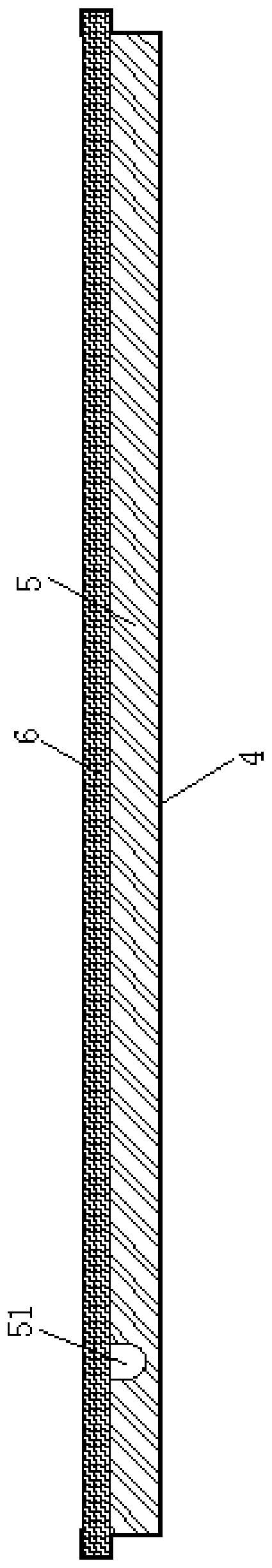

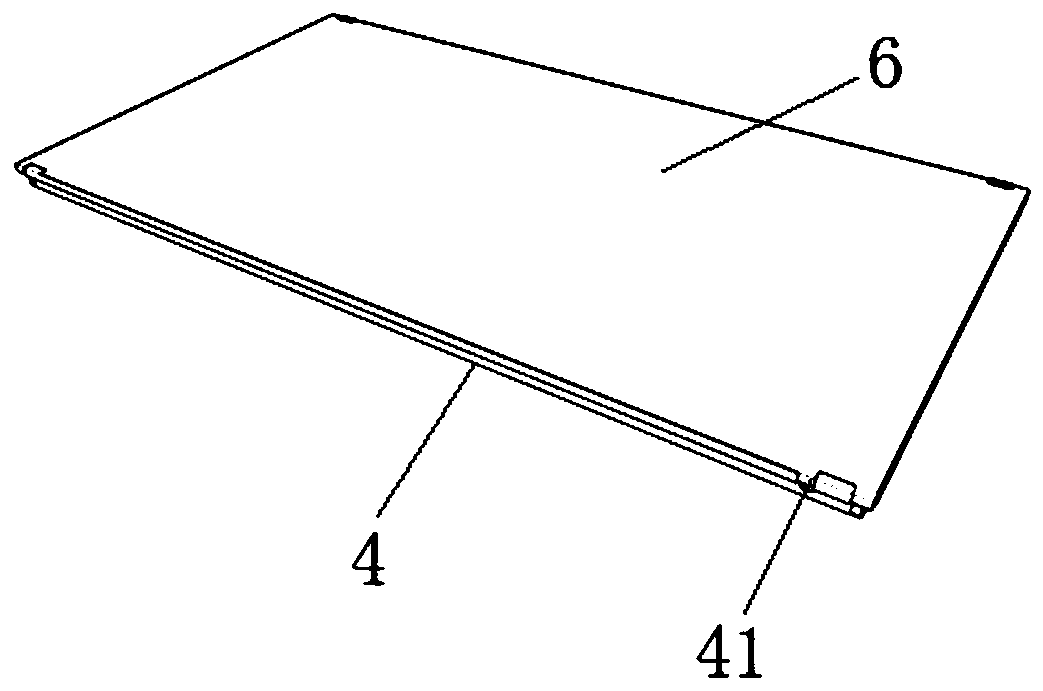

[0035] see Figure 1 to Figure 5 , the figure shows a prefabricated ground overhead floor heating installation structure provided by Embodiment 1 of the present invention, which includes: a frame assembly, which includes a keel 1, a connecting leveling member 2 and a base plate 3, and the keel 1 is leveled by connecting The parts 2 are connected to each other to form a plurality of connected frame units. The base plate 3 is arranged on the keel 1, and one frame unit corresponds to one base plate 3, and the surroundings of the base plate 3 correspond to four keel 1s; the floor heating component includes multiple mutual The spliced floor heating unit, the floor heating unit includes a cladding board 4, a thermal insulation board 5, and a balance board 6 arranged sequentially from bottom to bottom, and the edge of the cladding board 4 covers the edges of the thermal insulation board 5 and the balance board 6; the inside of the thermal insulation board 5 A pipeline channel 51 is...

Embodiment 2

[0045] see Figure 5 to Figure 8 , the figure shows a prefabricated ground overhead floor heating installation structure provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: connection adjustment The flat part 2 includes a bearing platform 21, a connecting plate 22 arranged on the side of the bearing platform 21, a connecting platform 23 arranged on the bearing platform 21, and an adjusting screw 24. The connecting platform 23 protrudes from the bearing platform 21, and the adjusting screw 24 threads Connect the center of the bearing platform 21 and the connecting platform 23, and the adjusting screw 24 is located at the bottom of the bearing platform 21; the end of the keel 1 is sleeved on the connecting plate 22 and docked with the end of the connecting platform 23; the end of the keel 1 It is in the shape of "convex"; the connection table 23 is in t...

Embodiment 3

[0047] see Figure 7 , the figure shows a prefabricated ground overhead floor heating installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: carrying platform 21 and the center of the connection table 23 are provided with an adjustment hole 25, and the adjustment screw rod 24 is threadedly connected to the adjustment hole 25, and the adjustment hole 25 is a through hole; the top of the adjustment screw rod 24 is provided with a "one" word groove 241; Including a support pad 26, the support pad 26 is arranged at the bottom of the adjusting screw 24, and the support pad 26 is circular. Through the setting of the above structure, the "one" groove is exposed on the top of the adjustment hole 25, and the adjustment screw 24 can be rotated through the "one" groove 241 on the top to achieve the purpose of adjustment; the support pad 26 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com