Environmentally-friendly process apparatus for synthesizing furanone

A technology of process equipment and furanone, which is applied in the field of furanone synthesis equipment, can solve the problems of no synthetic equipment, low yield of furanone, and potential safety hazards, so as to reduce and eliminate pollution, reduce potential safety hazards, and realize The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

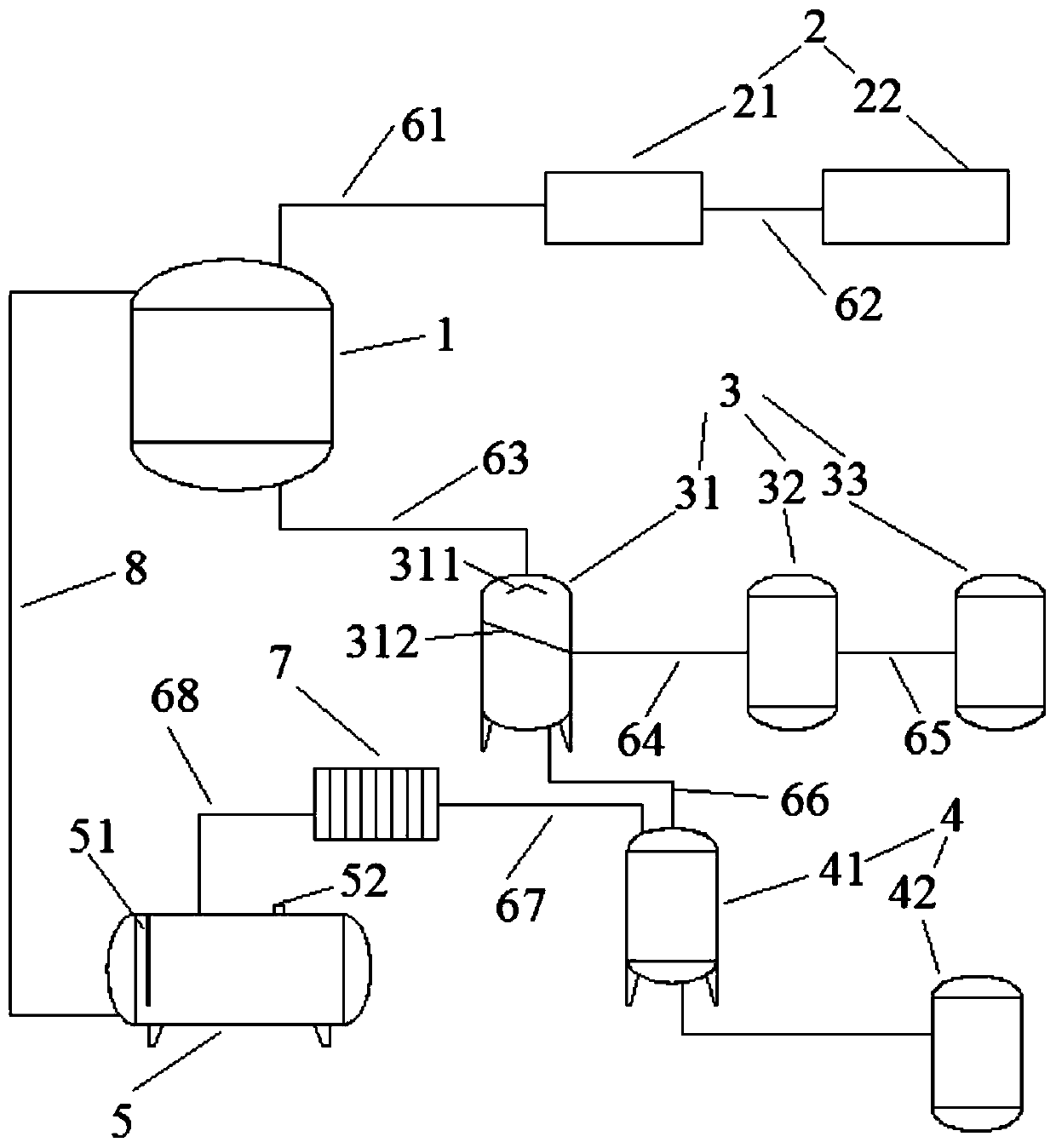

[0016] A furanone synthetic environmental protection process equipment, including a reactor 1, a hydrogen recovery device 2, a zinc recovery device 3, a zinc acetate recovery device 4 and a distilled water recycling tank 5, is characterized in that the top of the reactor 1 is connected to the hydrogen recovery device through a pipeline Device 2, the hydrogen recovery device 2 includes an adsorption drying device 21 and a hydrogen collection device 22, the top of the reactor 1 is connected to the adsorption drying device 21 through a first pipeline 61, and the adsorption drying device 21 is connected to the hydrogen collection device through a second pipeline 62 22; the bottom of the reactor 1 is connected to the zinc recovery device 3 through the third pipeline 63, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com