Method for reducing acidolysis solid matters in titanium dioxide production process

A production process and technology of titanium dioxide, applied in the direction of titanium compounds, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that there are too many residual solids in the acidolysis tank, the heat dissipation of the main reaction is not timely, and the pressure air stirring is not enough. Uniformity and other problems, to achieve the stability of various indicators, reduce the risk of running the pot, and reduce the effect of solid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

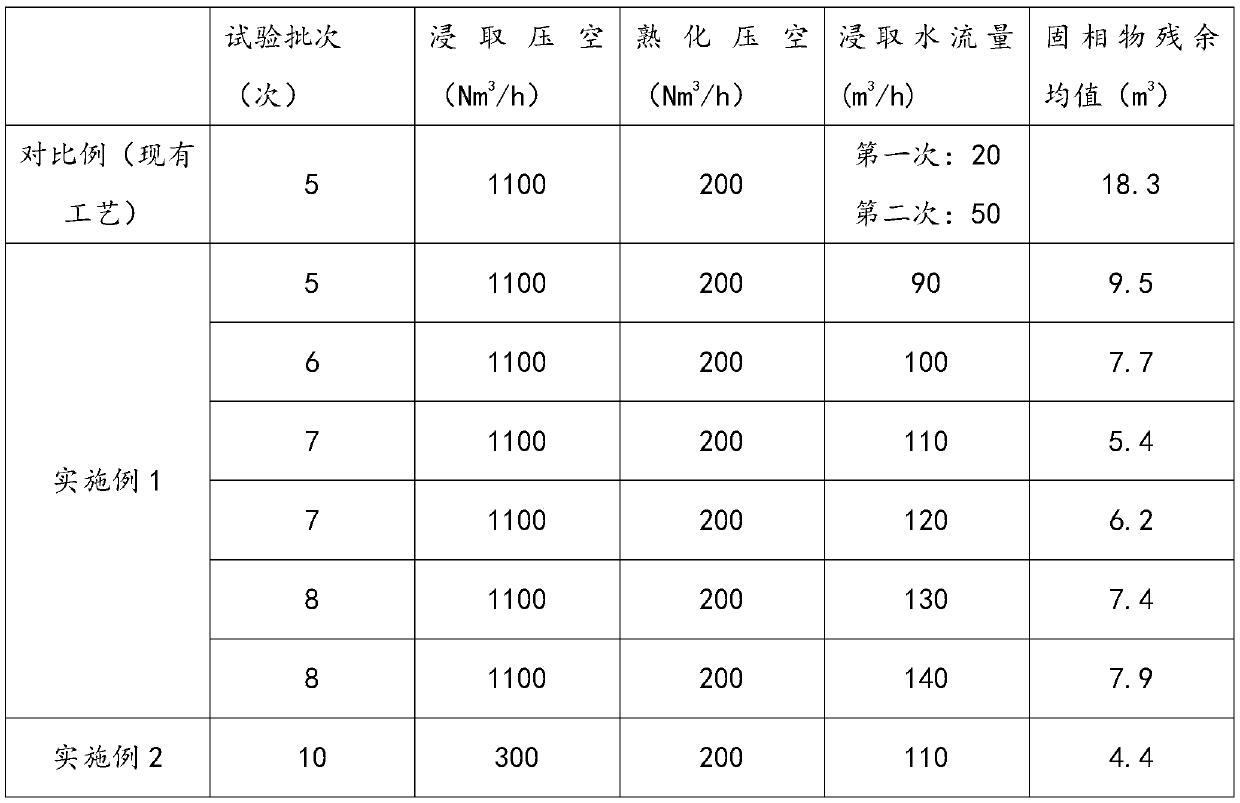

Embodiment 1

[0047] The steps of this embodiment and the amount of addition of each material are consistent with those of the comparative example, the difference is only that the process parameters of the process of adding leaching water have been adjusted, specifically:

[0048] 1. After the two steps of acidolysis and aging in the acidolysis reactor, check whether the material condition in the acidolysis tank is normal.

[0049]2. The main operator of acid hydrolysis sets the amount of leaching water and small amount of water according to the process requirements. After the delay of blowing the solid phase for 15 minutes, the main operator judges whether the leaching can be performed, and then starts the acid hydrolysis tank for leaching. Water intake manual valve.

[0050] 3. The main operator of acid hydrolysis opens the manual valve of the leaching water of the acid hydrolysis tank, closes the manual valves of the leaching water of other related acid hydrolysis tanks, and judges that ...

Embodiment 2

[0060] The steps of this embodiment and the addition amount of each material are consistent with the comparative example, the only difference is that the process parameters of the process of adding leaching water and the air flow rate of each step have been adjusted, specifically:

[0061] 1. After the two steps of acidolysis and aging in the acidolysis reactor, check whether the material condition in the acidolysis tank is normal.

[0062] 2. The main operator of acid hydrolysis sets the amount of leaching water and small amount of water according to the process requirements. After the delay of blowing the solid phase for 15 minutes, the main operator judges whether leaching can be carried out, and then starts the acid hydrolysis tank for leaching. Water intake manual valve.

[0063] 3. The main operator of acid hydrolysis opens the manual valve of the leaching water of the acid hydrolysis tank, closes the manual valves of the leaching water of other related acid hydrolysis t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com