Tapered roller bearing inner ring and outer sleeve oil groove machining process

A tapered roller bearing and processing technology, which is applied in the field of lathe processing, can solve the problems of affecting the structural strength of parts, small width tolerance, lack of oil storage, dust storage raceway grinding overrun, etc., to achieve convenient The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

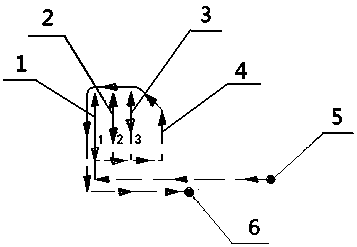

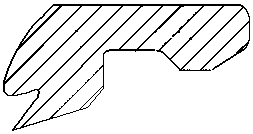

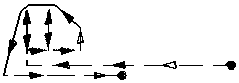

[0042] The processing technology of the inner ring and the outer casing oil groove of the tapered roller bearing includes the outer casing oil groove processing procedure and the inner ring oil groove processing procedure. The outer casing oil groove processing and the inner ring oil groove processing both include the processing of oil grooves of different shapes. The specific steps are as follows:

[0043] a. The oil groove processing of different jackets is divided into the oil groove processing under the condition of not grinding the blade and the oil groove processing under the condition of grinding the blade;

[0044] (1) The width of the oil groove processed without grinding the blade is not limited, specifically, it can be processed at any angle within 90° in the L direction, and the angle in the R direction is not less than 35°;

[0045] (2) The narrowest 0.8 mm 90° oil groove is processed by grinding blade;

[0046] b. Processing of different inner ring oil grooves: m...

Embodiment 2

[0050] The processing technology of the inner ring and the outer casing oil groove of the tapered roller bearing includes the outer casing oil groove processing procedure and the inner ring oil groove processing procedure. The outer casing oil groove processing and the inner ring oil groove processing both include the processing of oil grooves of different shapes. The specific steps are as follows:

[0051] a. The oil groove processing of different jackets is divided into the oil groove processing under the condition of not grinding the blade and the oil groove processing under the condition of grinding the blade;

[0052] (1) The width of the oil groove processed without grinding the blade is not limited, specifically, it can be processed at any angle within 90° in the L direction, and the angle in the R direction is not less than 35°;

[0053] (2) The narrowest 0.8 mm 90° oil groove is processed by grinding blade;

[0054] b. Processing of different inner ring oil grooves: mod...

Embodiment 3

[0058] The processing technology of the inner ring and the outer casing oil groove of the tapered roller bearing includes the outer casing oil groove processing procedure and the inner ring oil groove processing procedure. The outer casing oil groove processing and the inner ring oil groove processing both include the processing of oil grooves of different shapes. The specific steps are as follows:

[0059] a. The oil groove processing of different jackets is divided into the oil groove processing under the condition of not grinding the blade and the oil groove processing under the condition of grinding the blade;

[0060] (1) The width of the oil groove processed without grinding the blade is not limited, specifically, it can be processed at any angle within 90° in the L direction, and the angle in the R direction is not less than 35°;

[0061] (2) The narrowest 0.8 mm 90° oil groove is processed by grinding blade;

[0062] b. Processing of different inner ring oil grooves: m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com