Portable device for derusting metal surface through semiconductor laser

A metal surface and semiconductor technology, which is applied in the field of portable semiconductor laser derusting devices for metal surfaces, can solve problems such as difficult handling of metal solutions, damage to metal surfaces, and inability to ensure thorough derusting, achieving better derusting effects and thorough rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

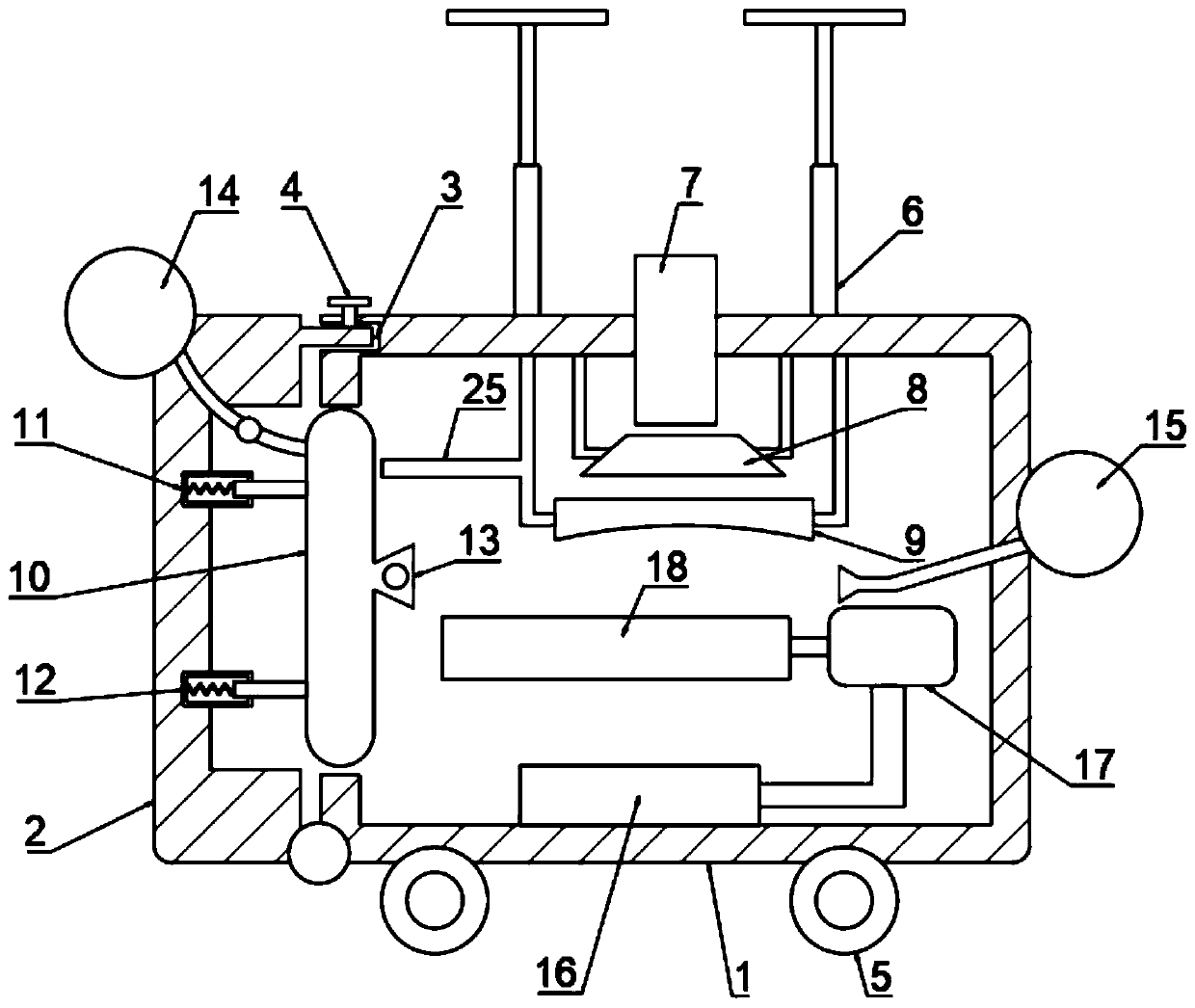

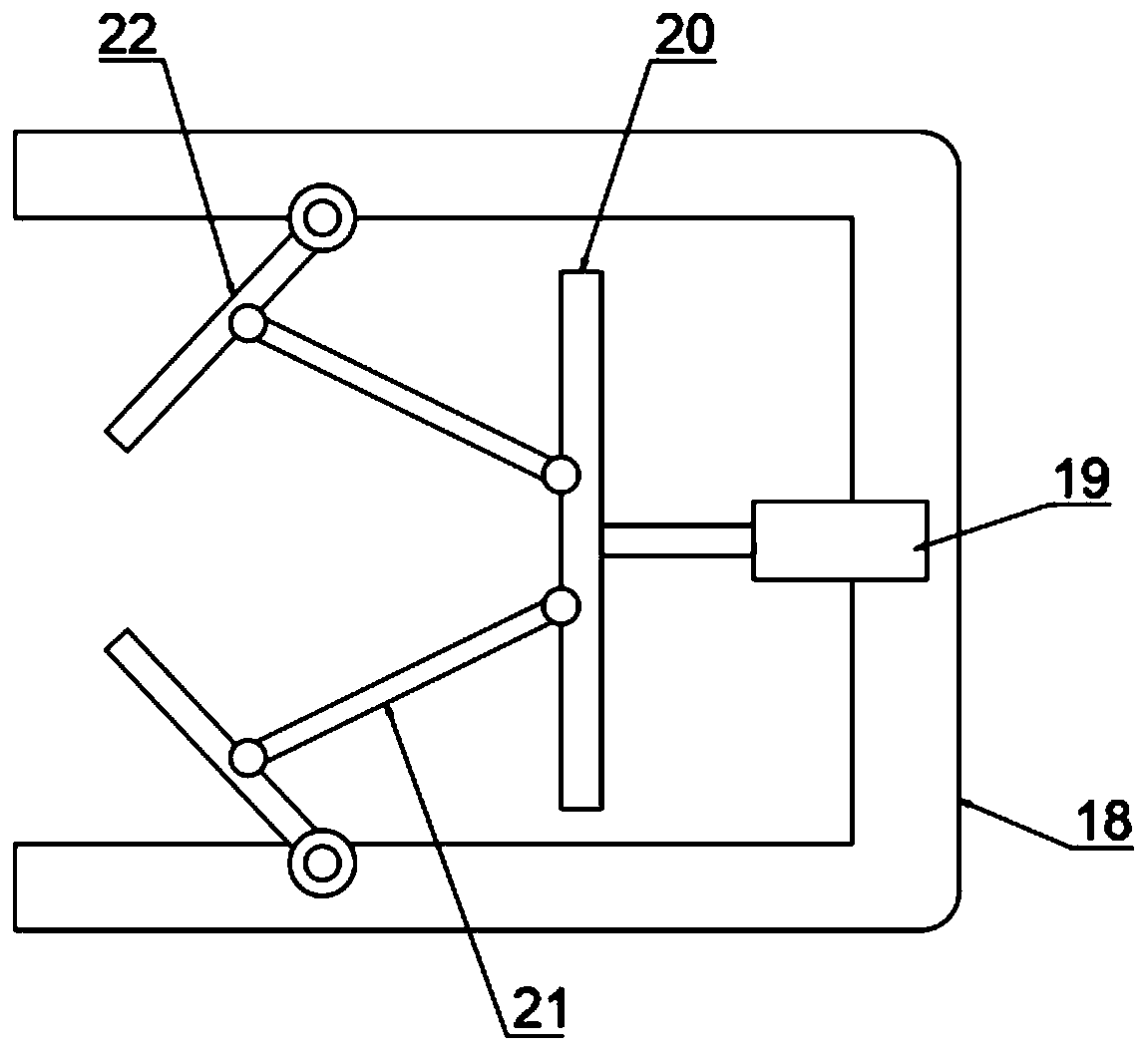

[0032] refer to Figure 1-2 , a portable semiconductor laser derusting device for metal surfaces, comprising a box 1, one end of the box 1 is rotatably connected to an end cover 2, and a connecting mechanism is provided between the end cover 2 and the box body 1, and the connecting mechanism includes a In the groove 3 on the side of the box body 1 close to the end cover 2, the side of the end cover 2 close to the box body 1 is integrally formed with a plug plate that matches the groove 3, and the upper side wall of the box body 1 is screwed to extend to the groove. The bolt 4 in the groove 3, when closing the end cover 2, turn the end cover 2 until the inserting plate is inserted into the groove 3, and turn the bolt 4 down to contact the inserting plate to complete the fixing of the end cover 2 and complete the box body 1 The closure prevents debris from entering.

[0033] A plurality of rollers 5 are installed on the lower side wall of the box body 1, and two pull rods 6 are...

Embodiment 2

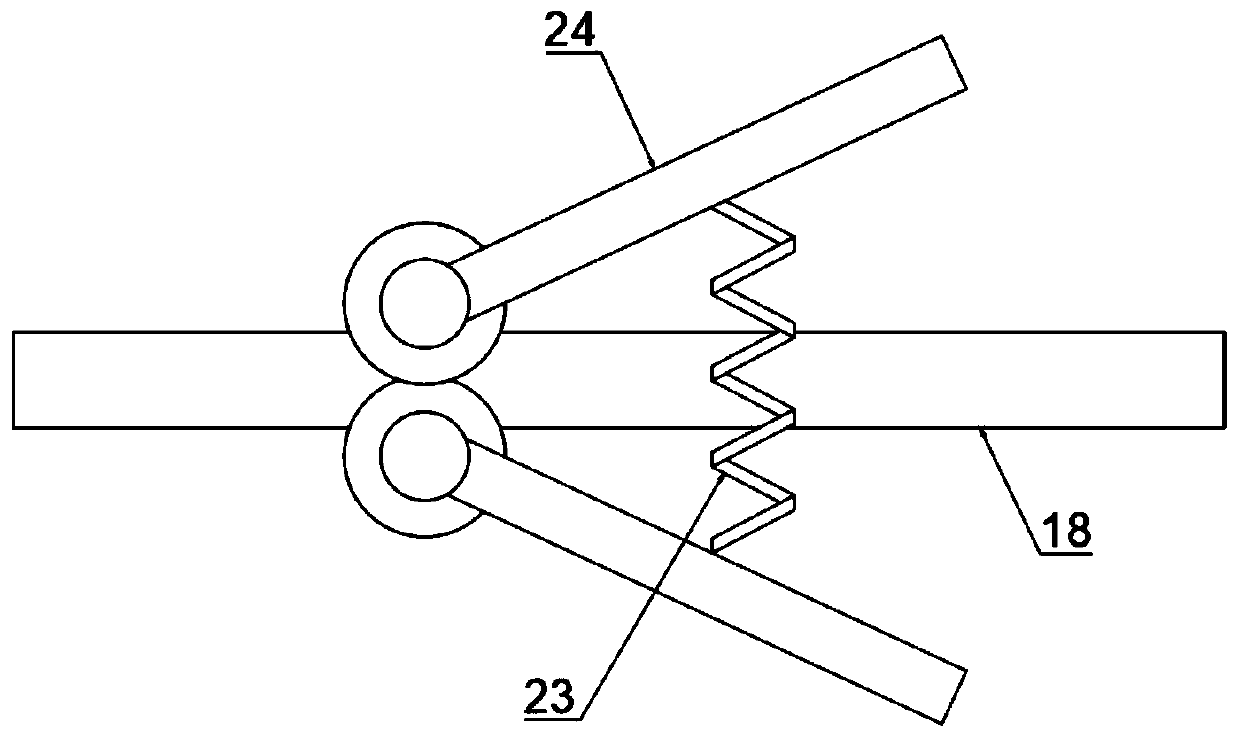

[0040] refer to image 3 The difference with Embodiment 1 is that the fixing mechanism 18 includes a rod body, and two rotating rods 24 are connected symmetrically to rotate on the outer wall of the rod body, and a return spring 23 is fixedly connected between the two rotating rods 24, and the workpiece to be fixed directly Covered on the outer wall of the rod body, the end of the rotating rod 24 is pressed against the inner wall of the workpiece by the elastic force of the return spring 23 to complete the fixing of the workpiece. Unlike the first embodiment, it is more suitable for fixing the pipe fittings. The first embodiment It is more suitable for fixing plate-shaped workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com