Eight-degree-of-freedom local force feedback bionic upper limb exoskeleton master manipulator

A degree of freedom and force feedback technology, applied in the direction of passive exercise equipment, physical therapy, etc., can solve the problems of heavy burden on the human body, fixed use only, large structural size, etc., and achieve the effect of intuitive control and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

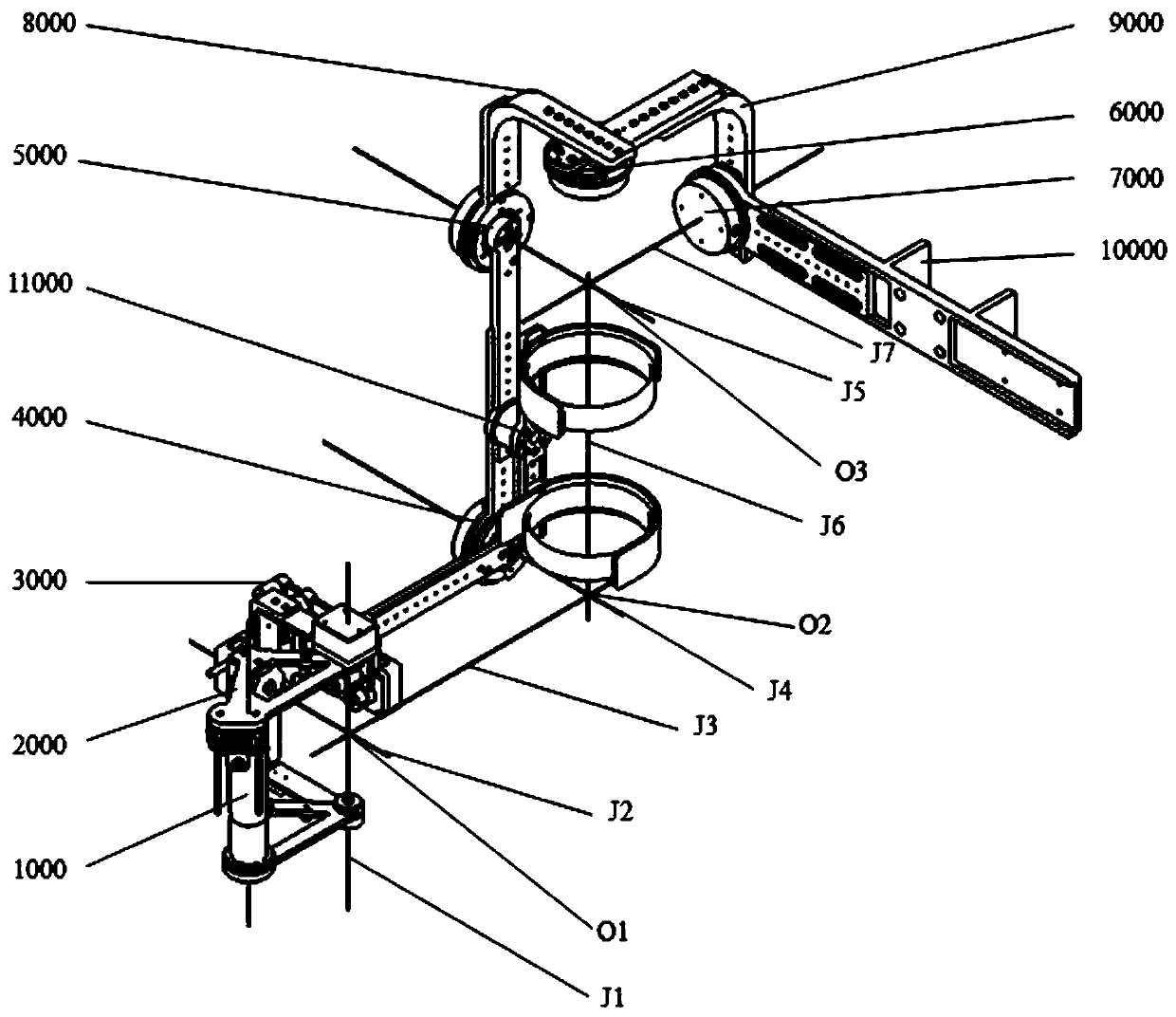

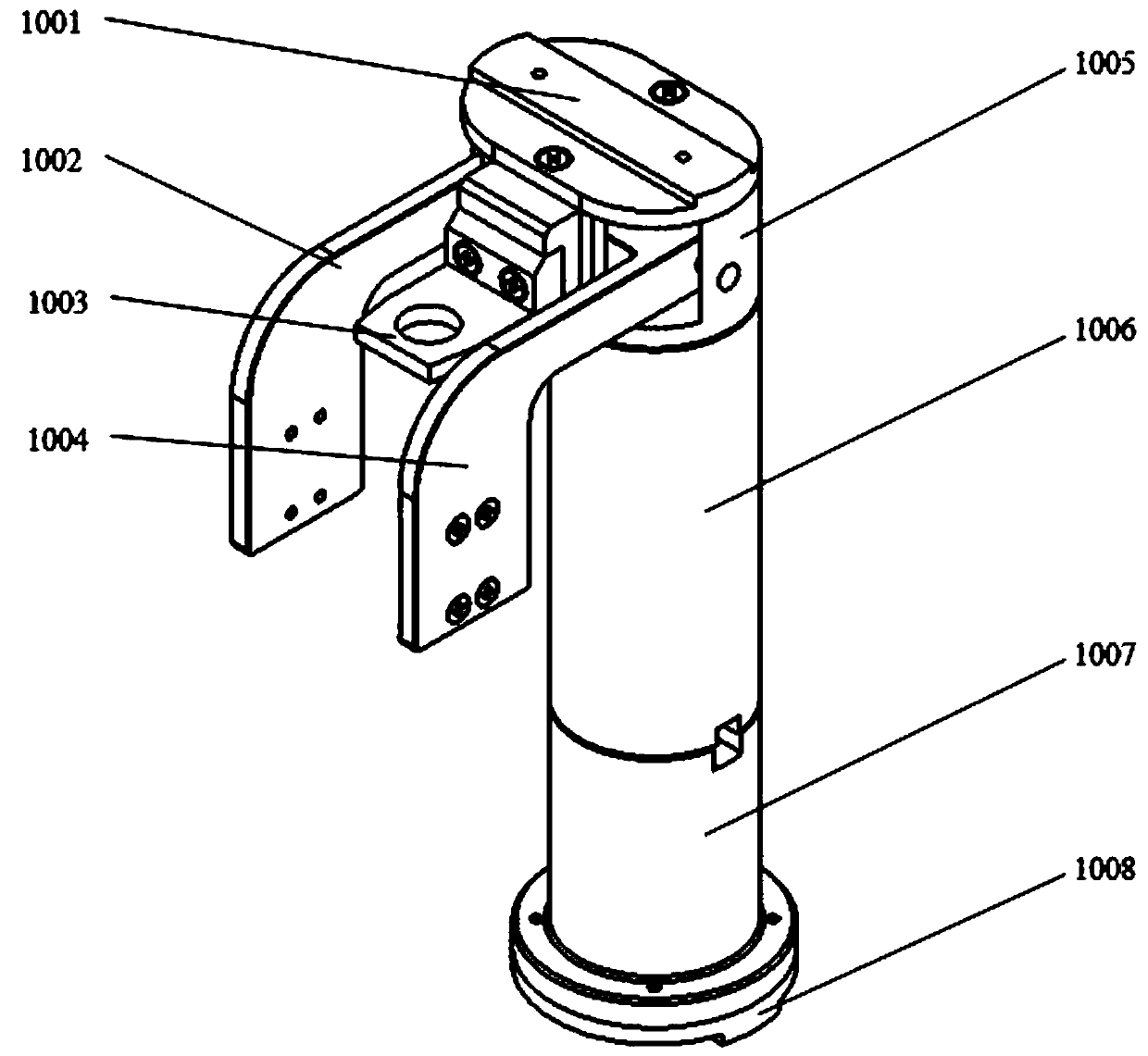

[0036] Such as figure 1 As shown, the present invention includes a free force feedback hand assembly 1000, a two-degree-of-freedom wrist joint assembly 2000, a one-degree-of-freedom forearm rotation assembly 3000, a one-degree-of-freedom elbow joint assembly 4000, a one-degree-of-freedom shoulder flexion-extension assembly 5000, a 6000 degrees of freedom shoulder rotation assembly, 7000 degrees of freedom shoulder abduction and adduction assembly, shoulder adjustment plate A8000, shoulder adjustment plate B9000, back adjustment plate 10000 and upper arm strap assembly 11000, of which two degrees of freedom wrist joint Assembly 2000 includes volar flexion and dorsiflexion joint assembly 2010 and ulnar flexion and flexion joint assembly 2020 that are rotatably connected. A free force feedback hand assembly 1000 is installed on palmar and dorsiflexion joint asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com