Fuse insulation protection sleeve and preparation method thereof

A technology for insulating protective sleeves and fuses, applied in chemical instruments and methods, emergency protection devices, electrical components, etc., can solve the problems of cumbersome and inconvenient replacement of fuses, and achieve the effect of improving safety and convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of fuse insulation protection cover of the present invention is;

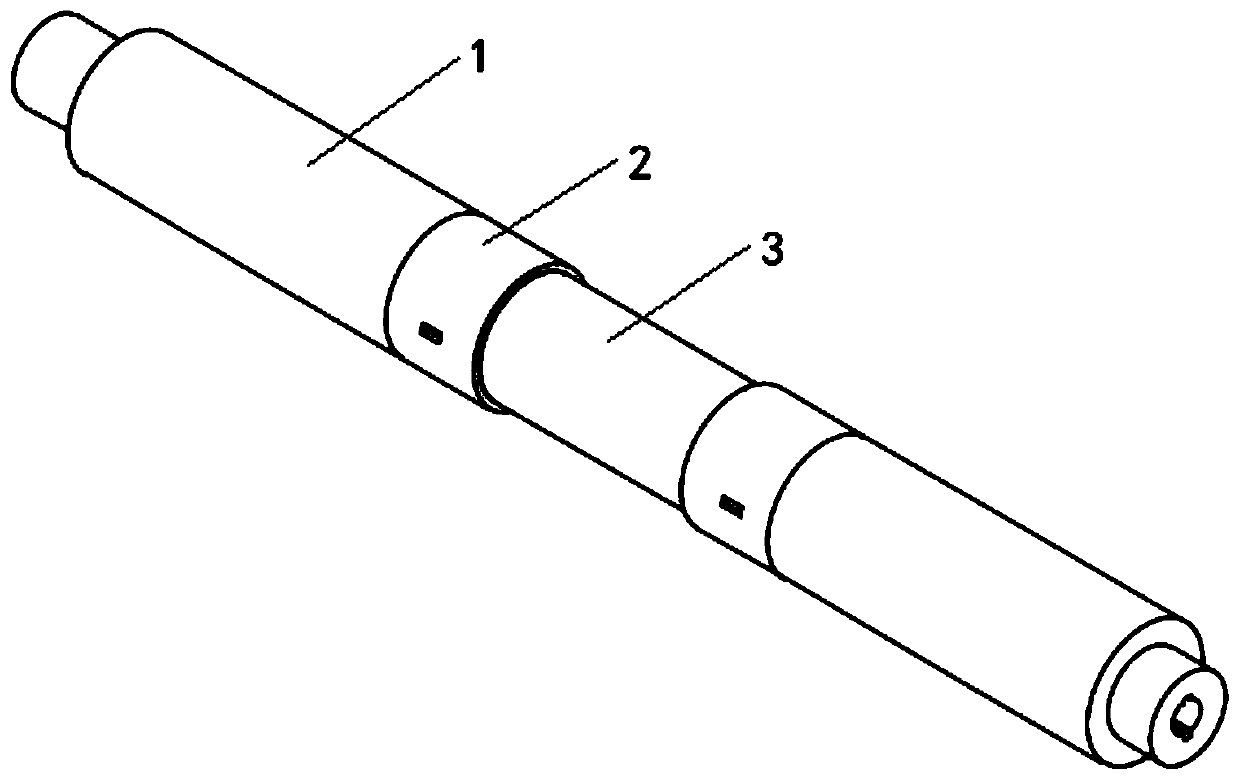

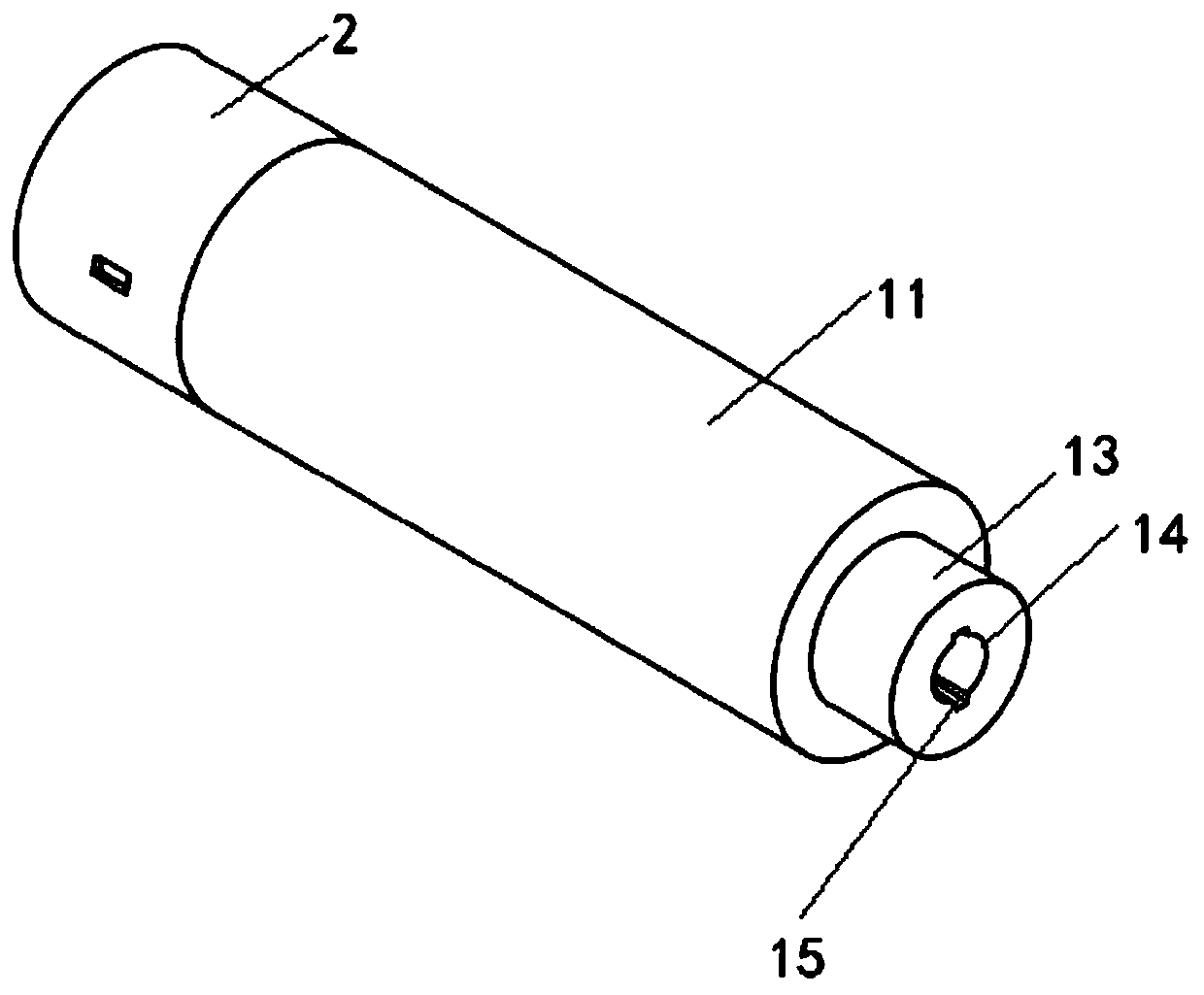

[0057] Step 1. Prepare the wire leg fixing cylinder 1 and the connecting cylinder 2, and install the spring sheet in the installation groove 15 of the wire leg fixing cylinder 1, wherein the wire leg fixing cylinder 1 and the connecting cylinder 2 are made of high temperature resistant hard insulating material, preferably , the rigid insulating material is thermoplastic polyimide;

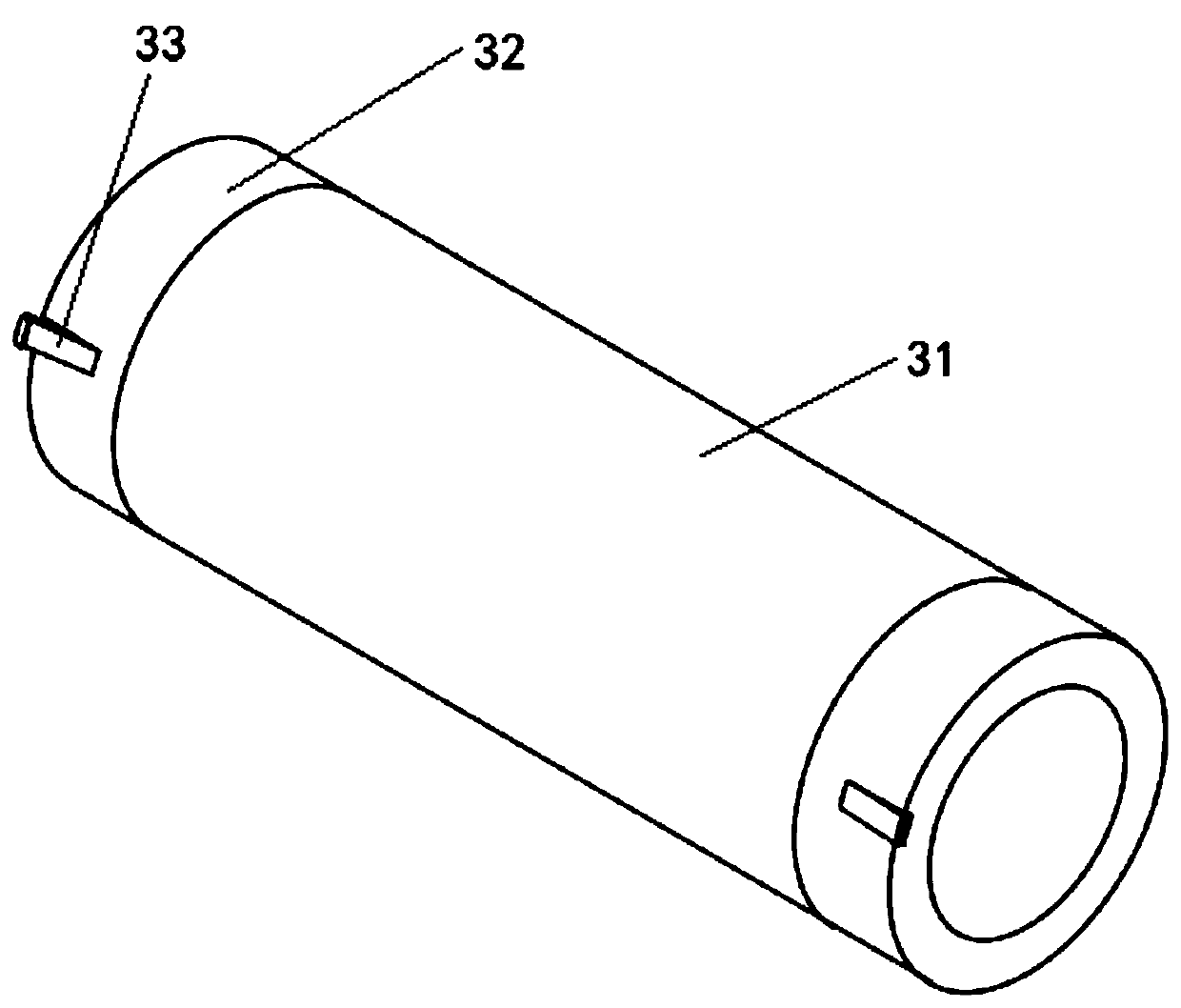

[0058] Step 2: Prepare the terminal 32 through a high temperature resistant hard insulating material, fix the spring leaf on the side wall of the terminal 32, prepare the sleeve core 31 through a high thermal conductivity insulating composite material, and place the two ends of the formed sleeve core 31 respectively After being sleeved on the terminal 32, the two are fixedly connected, and the fixed connection method is hot-melt connection, and the high-temperature-resistant hard insulating material is ...

Embodiment 2

[0071] The preparation method of the insulating layer is:

[0072] S1. Take sodium alkylbenzene sulfonate as a dispersant and add it to deionized water to dissolve, then add calcium fluoride to it, wait for the calcium fluoride to stir and disperse to obtain a calcium fluoride dispersion, and add polyethylene to the calcium fluoride dispersion alcohol, heated and stirred to obtain a viscous dispersion;

[0073] S2, using a coupling agent to treat the thermally conductive insulating particles, adding the treated thermally conductive insulating particles to the viscous dispersion obtained in the previous step, stirring and mixing, so that the thermally conductive insulating particles are uniformly dispersed in the viscous dispersion, and a thermally conductive filling material is obtained;

[0074] S3. Take the phenolic resin and polyvinyl chloride and heat and stir after uniform mixing. The phenolic resin and polyvinyl chloride are melted and mixed to obtain a mixed resin, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com