Method for evaluating quality of folium artemisiae argyi

A technology of quality assessment and artemisia leaf, applied in the field of quality assessment of mugwort leaves, can solve the problems of complex pre-treatment process of mugwort leaves, affecting the accuracy of mugwort leaf quality evaluation, incomplete quality evaluation of mugwort leaves, etc., to speed up the quality evaluation process, pertinence and practicality The effect of good performance and accurate quality assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

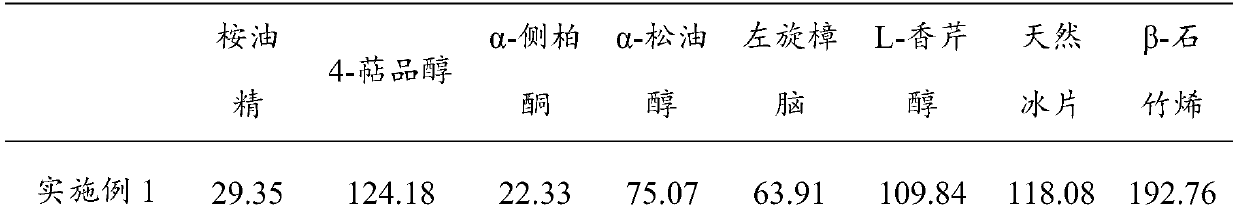

Embodiment 1

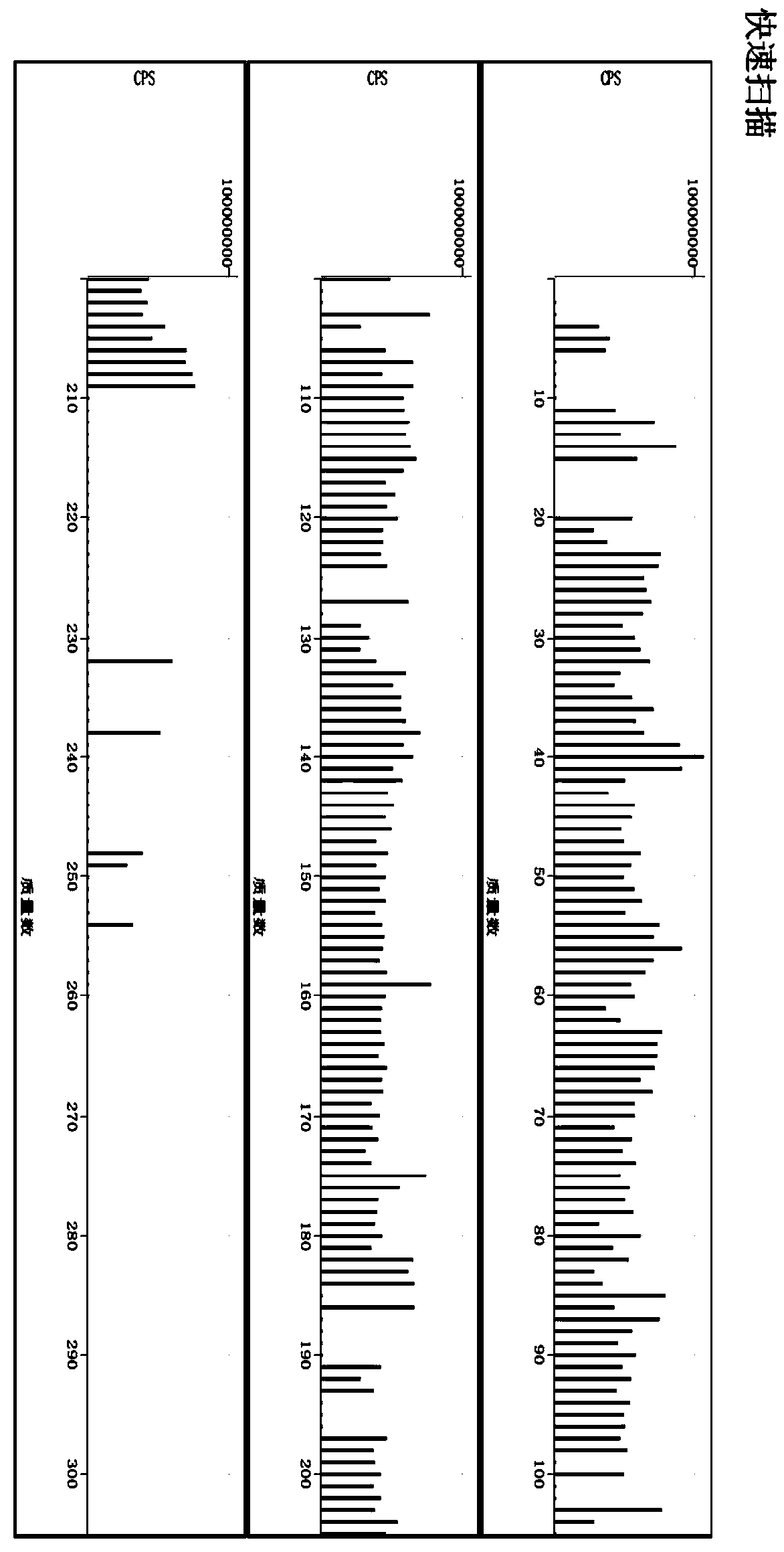

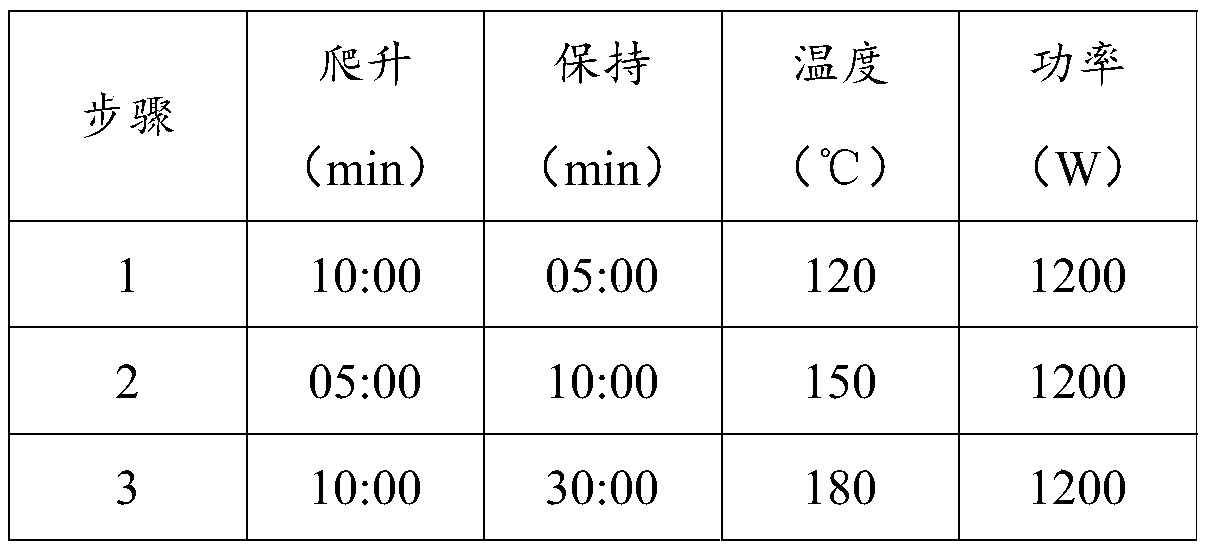

[0034] S1 Measurement of main component content: headspace-gas chromatography-mass spectrometry is used to quantitatively measure the main components in Artemisia argyi. The specific steps are as follows:

[0035] S11 Preparation of the test solution: crush Artemisia argyi (e.g., Nanyang Artemisia) in advance until it passes through a No. 4 sieve (ie 65 mesh), mix well, accurately weigh 0.8g of Artemisia argyi powder into a 20ml headspace bottle, add 7ml of ultra-pure water, seal the headspace bottle, shake well, and let it stand for 30 minutes to obtain the test solution.

[0036] Preparation of S12 reference substance solution: Accurately weigh the reference substances eucalyptol, thujone, L-camphor, and natural borneol, add methanol to dissolve, and prepare mixed reference substances of 0.01, 0.02, 0.04, 0.1, 0.2, and 0.4 mg / ml Solution, measure 1000ul mixed reference substance solution to 20ml headspace bottle, add 10ml water, seal the headspace bottle, shake well, let sta...

Embodiment 2

[0059] The embodiment of the present invention is basically the same as embodiment 1, the difference is:

[0060] When measuring the content of the main components in step S1, in the step S11, crush the leaves of mugwort in advance until they pass through a No. Pure water, seal the headspace bottle, shake well, and let it stand for 25 minutes to obtain the test solution.

[0061] In the step S12, accurately weigh the reference substances eucalyptol, thujone, L-camphor, and natural borneol, add methanol to dissolve, and prepare mixed reference substance solutions of 0.01, 0.02, 0.04, 0.1, 0.2, and 0.4 mg / ml , Measure 1000ul of the mixed reference substance solution into a 20ml headspace bottle, add 10ml of water, seal the headspace bottle, shake well, and let stand for 25min to obtain the reference substance solution.

[0062] When measuring the content of inorganic elements in step S2, in the step S211, pulverize the leaves of mugwort in advance to pass through No. 5 sieve (i...

Embodiment 3

[0064] The embodiment of the present invention is basically the same as embodiment 1, the difference is:

[0065] When measuring the main component content in step S1, in the step S11, crush the leaves of mugwort to 70 mesh in advance, mix well, accurately weigh 1.0g of leaves of mugwort powder into a 20ml headspace bottle, add 12ml of ultrapure water, and seal the headspace bottle, shake well, and let it stand for 20 minutes to obtain the test solution.

[0066] In the step S12, accurately weigh the reference substances eucalyptol, thujone, L-camphor, and natural borneol, add methanol to dissolve, and prepare mixed reference substance solutions of 0.01, 0.02, 0.04, 0.1, 0.2, and 0.4 mg / ml , Measure 1200ul of the mixed reference substance solution into a 20ml headspace bottle, add 13ml of water, seal the headspace bottle, shake well, and let stand for 20min to obtain the reference substance solution.

[0067] When measuring the content of inorganic elements in step S2, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com