Clutch cam ring blank detection equipment

A technology of testing equipment and cam ring, applied in the direction of instruments, measuring devices, etc., can solve the problems of online testing of unfavorable batch products, high cost of testing equipment, low testing efficiency, etc., so as to facilitate popularization, reduce testing costs and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

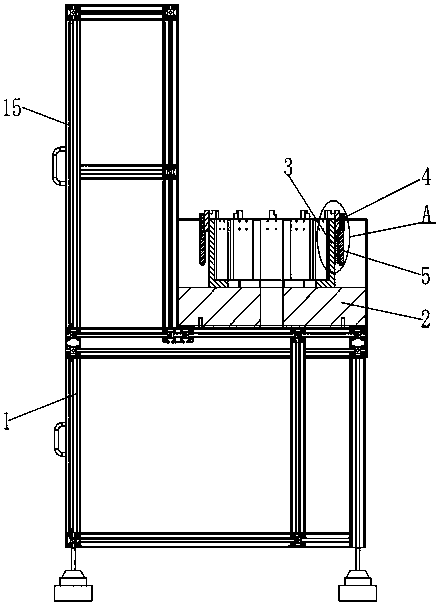

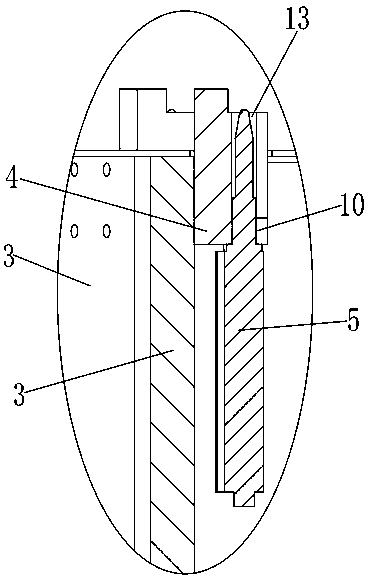

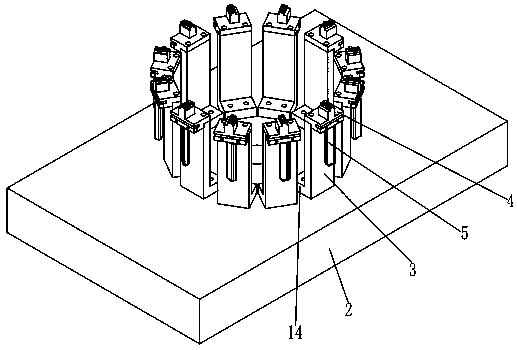

[0027] see Figure 1 to Figure 10 , the present invention provides a clutch cam ring blank detection equipment, comprising a base 1, a display device is provided on the left side of the upper surface of the base 1; a workbench 2 is provided on the right side of the upper surface of the base 1; The upper surface of the table 2 is provided with twelve flatness detection devices evenly distributed around the circumference; the flatness detection device includes a fixed plate 3 fixed on the upper surface of the workbench 2; a sensor fixture 4 is fixed on the upper end of the fixed plate 3 ; The sensor fixture 4 is provided with a matching sensor 5; the sensor 5 is clamped on the sensor fixture 4 by a clamping device.

[0028] The lower part of one side of the sensor fixing part 4 is provided with a gap 6, and the other side of the sensor fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com