Part cleanliness detection device and detection method

A detection device and component technology, applied in measurement devices, particle size analysis, material weighing, etc., can solve the problems of filter membrane pore blockage, cumbersome steps, reduced detection speed and detection accuracy, etc., to improve detection speed and simplify detection. process, the effect of improving inspection speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the present application.

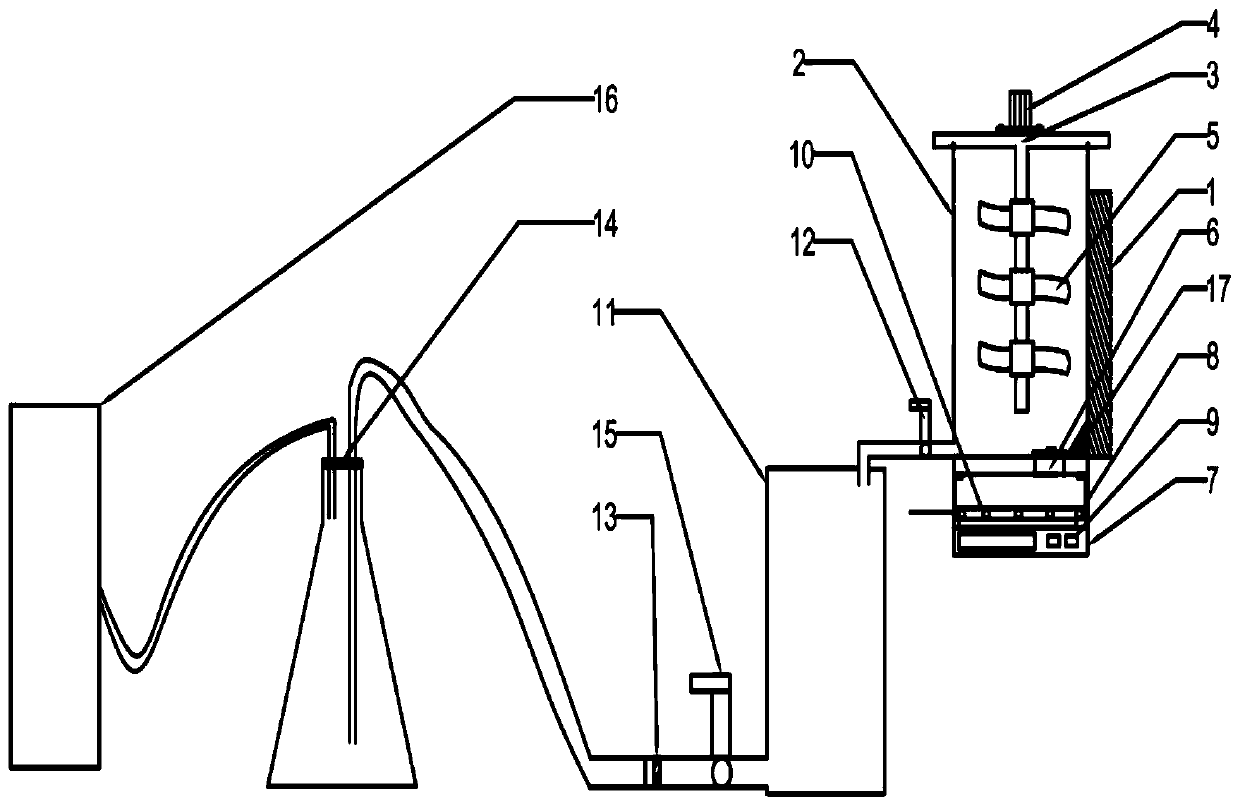

[0029] Such as figure 1 As shown, the invention provides a component cleanliness detection device (abbreviation detection device, see figure 1 ), including electromagnet 1, test solution storage container 2, drive motor 4, paddle 5, tray 8, electronic balance 9, test solution buffer bottle 11, filter membrane 13, recovery bottle 14 and vacuum pump 16;

[0030] The test solution storage container 2 is made of an iron material that can be adsorbed by an electromagnet. The top opening is provided with a top cover 3, and the bottom has a liquid outlet hole and is sealed by a bottom plug 6; the test solution storage container 2 is placed on On the supporting seat 7, the top of the supporting seat 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com