A kind of nylon masterbatch suitable for low-temperature nylon cable ties and its preparation method and application

A technology of nylon cable ties and nylon, which is applied in the field of polymer materials and processing, can solve the problems of reducing the release force of cable ties, reducing the viscosity of nylon, and easy yellowing of cable ties, so as to reduce injection molding time and excellent low temperature resistance , Improve the effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

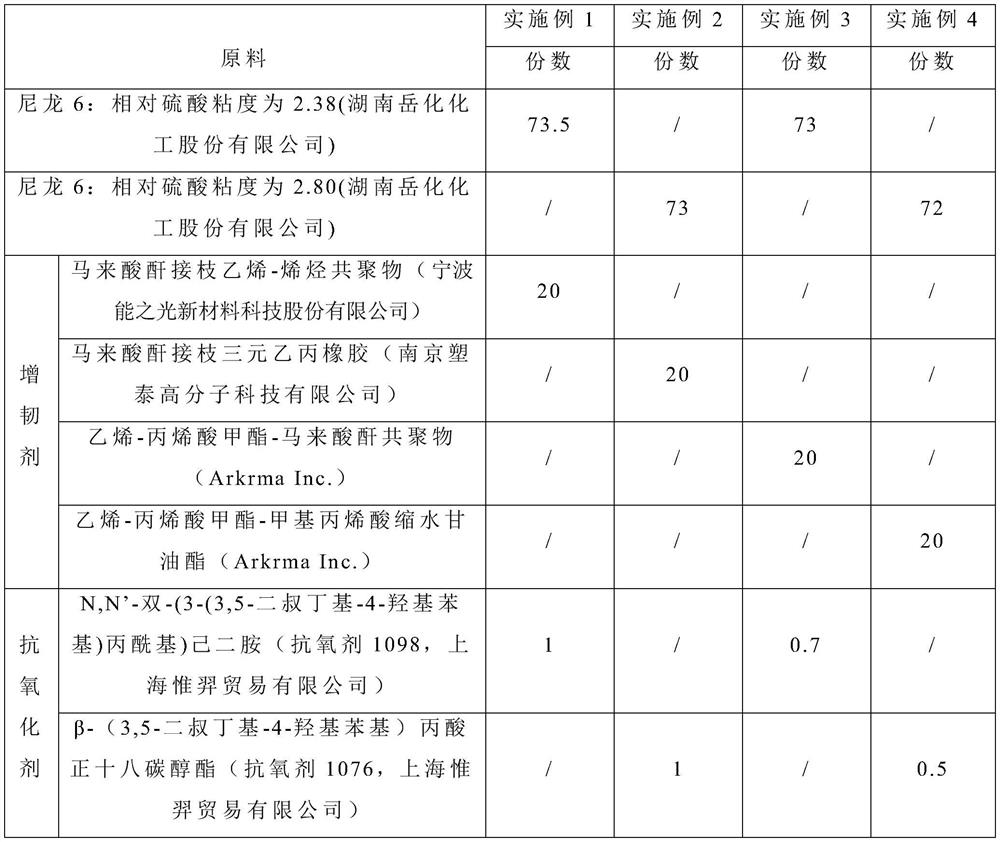

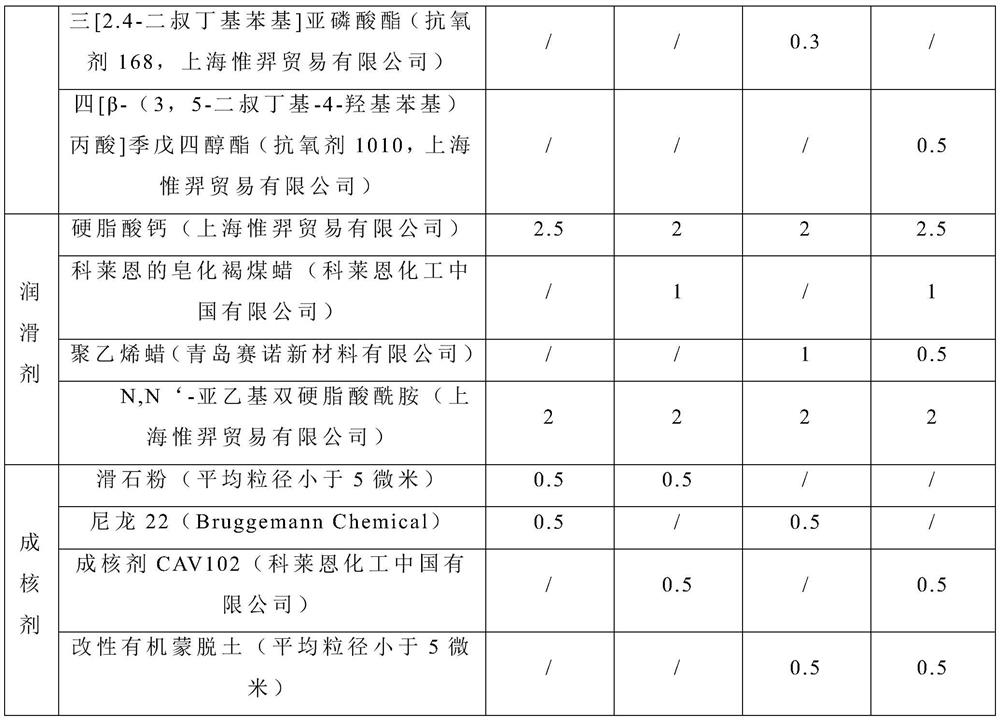

[0039] The raw material formula of the nylon masterbatch suitable for low-temperature nylon cable ties provided in these examples is shown in Table 1 below.

[0040] Table 1

[0041]

[0042]

[0043] The preparation method of the above-mentioned nylon masterbatch suitable for low-temperature nylon cable ties is: weighing each raw material according to the formula, mixing, extruding and granulating through a twin-screw extruder, drying at 80°C for 5 hours, and then it can be prepared; wherein, the The temperature settings of each zone of the twin-screw extruder from the main feed are: 120°C, 160°C, 180°C, 220°C, 250°C, 260°C, 230°C, 240°C, 240°C, 240°C, die temperature is 235°C.

Embodiment 5-8

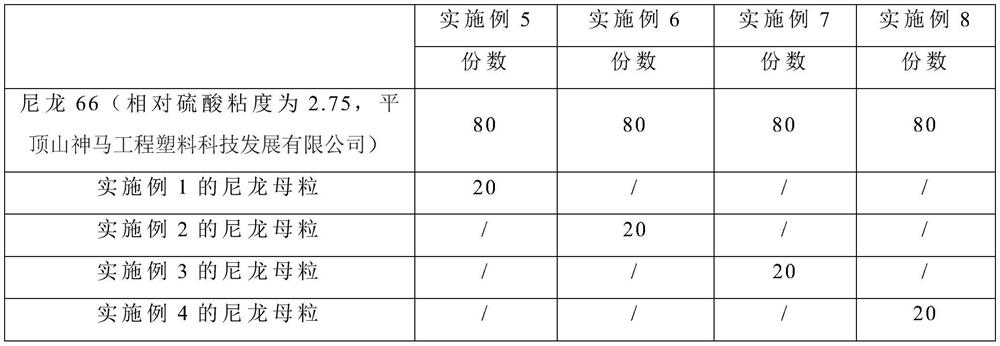

[0045] These embodiments provide low-temperature nylon cable ties, the raw material formula of which is shown in Table 2 below.

[0046] Table 2

[0047]

[0048] The preparation method of the above-mentioned nylon cable tie is as follows: Weigh the raw materials according to the formula, mix them, and inject them to make them; the heating temperatures in zones 1 to 4 are 265°C, 305°C, 325°C, and 315°C in sequence, and the injection pressure is 80MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com