Preparation method of plastic raw material beneficial to degradation

A raw material and plastic technology, applied in the field of plastic raw material preparation, can solve the problems of inability to ensure constant extrusion temperature, inconvenient raw material crushing and pre-mixing, and particle screening that cannot be mixed, and achieves easy industrial production, low cost, and protection environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

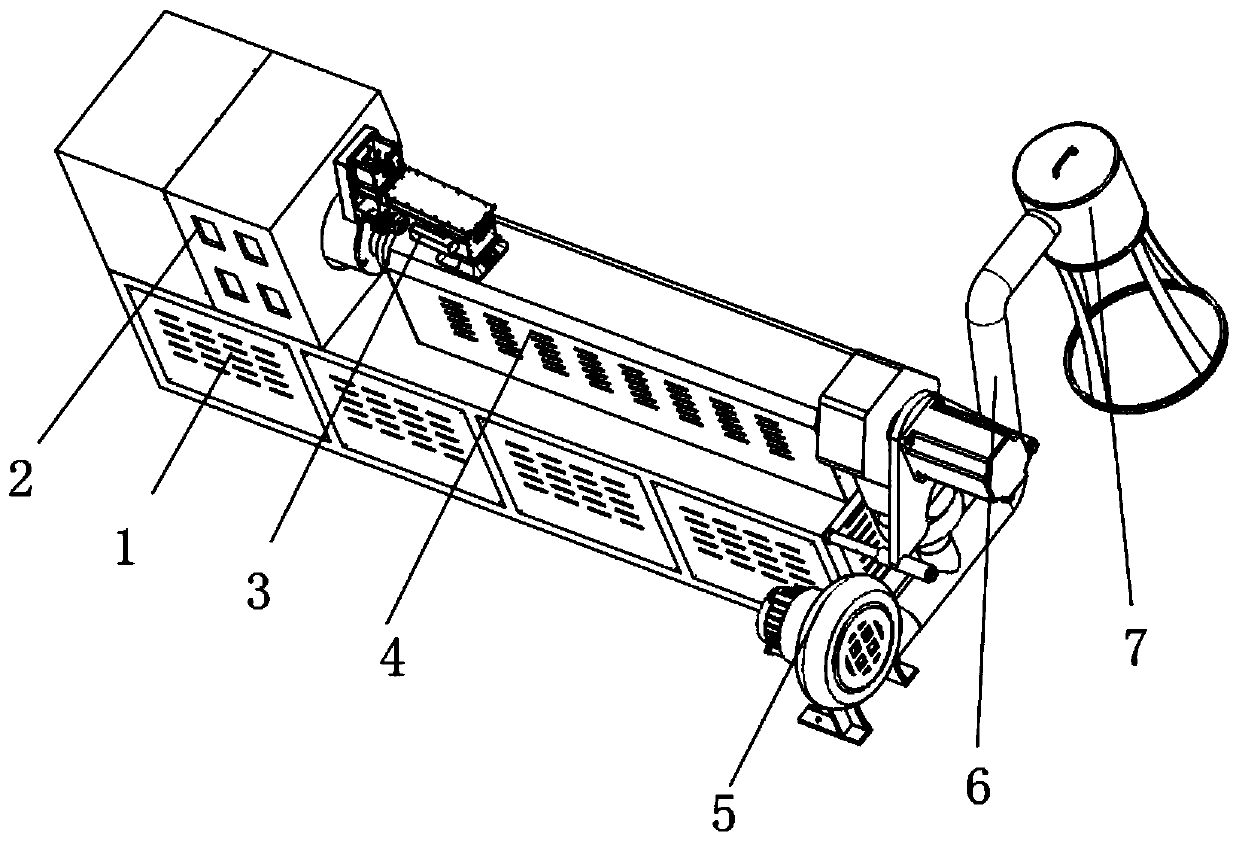

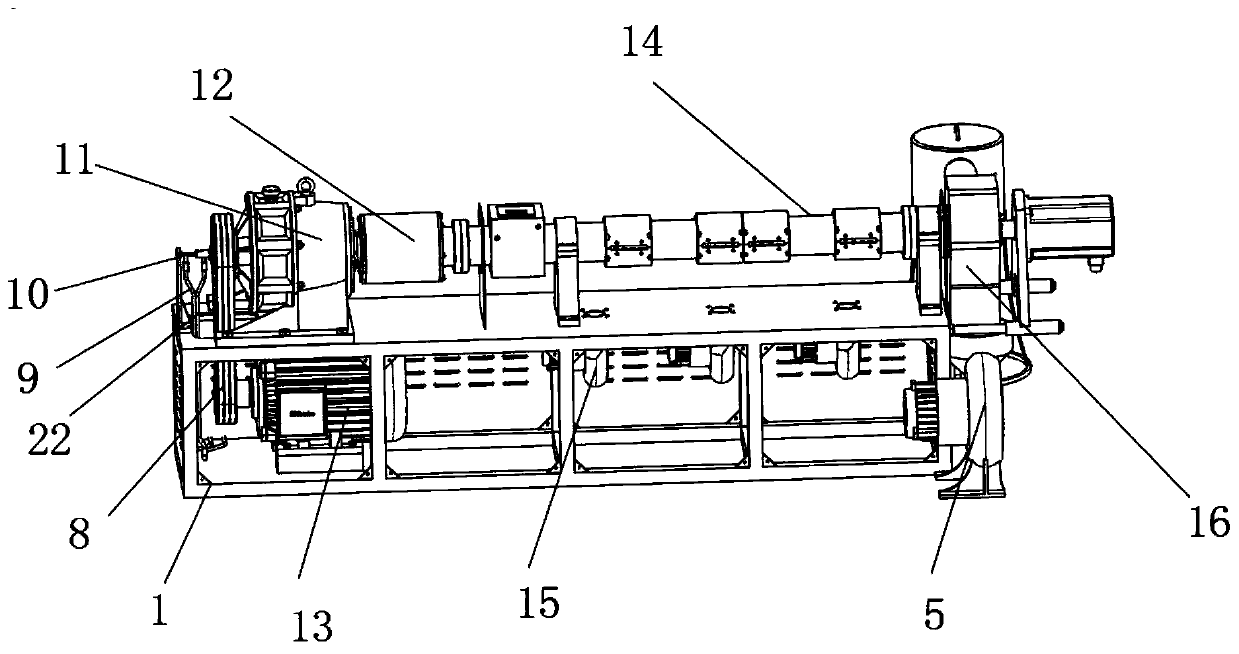

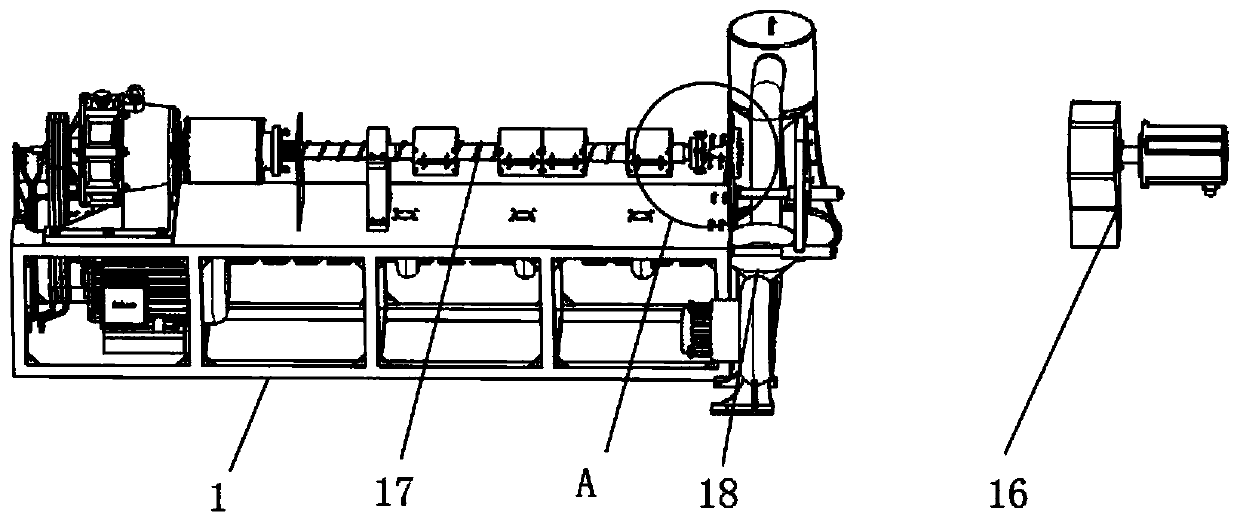

[0042] see Figure 1-8 Shown, a kind of preparation method that is beneficial to the plastic raw material of degradation comprises the following steps:

[0043] Step 1, in parts by weight, first weigh 60 parts of polyvinyl alcohol, 40 parts of n-butyraldehyde, 60 parts of hydrochloric acid and 0.5 part of sodium bicarbonate with a concentration of 31%; add 620 parts of distilled water into the dissolution kettle, and heat up to 72 ℃, slowly add polyvinyl alcohol under stirring, gradually raise the temperature to 95 ℃, and dissolve in the dissolution kettle at a constant temperature for 4 hours, so that the polyvinyl alcohol becomes an aqueous solution, and after filtering, transfer it to the acetal kettle, cool to 50 ℃ and add normal Butyraldehyde, continue to cool at 23°C, add hydrochloric acid, then keep at 20°C for 1 hour, at 25°C for 1.5 hours, at 30°C for 0.5 hours, at 40°C for 0.5 hours, at 45°C for 0.5 Hours, keep warm at 50°C for 0.5 hours, after the end of heat prese...

Embodiment 2

[0050] see Figure 1-8 Shown, a kind of preparation method that is beneficial to the plastic raw material of degradation comprises the following steps:

[0051] Step 1, in parts by weight, first weigh 40 parts of polyvinyl alcohol, 20 parts of n-butyraldehyde, 40 parts of hydrochloric acid and 0.3 part of sodium bicarbonate with a concentration of 31%; add 580 parts of distilled water into the dissolution kettle, and heat up to 68 ℃, slowly add polyvinyl alcohol under stirring, gradually raise the temperature to 95 ℃, and dissolve in the dissolution kettle at a constant temperature for 4 hours, so that the polyvinyl alcohol becomes an aqueous solution, and after filtering, transfer it to the acetal kettle, cool to 50 ℃ and add normal Butyraldehyde, continue to cool at 13°C, add hydrochloric acid, then keep at 18°C for 1 hour, at 20°C for 1.5 hours, at 25°C for 0.5 hours, at 35°C for 0.5 hours, at 40°C for 0.5 Hours, keep warm at 45°C for 0.5 hours, after the end of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com