Hydrophobicfood packaging film and preparation method thereof

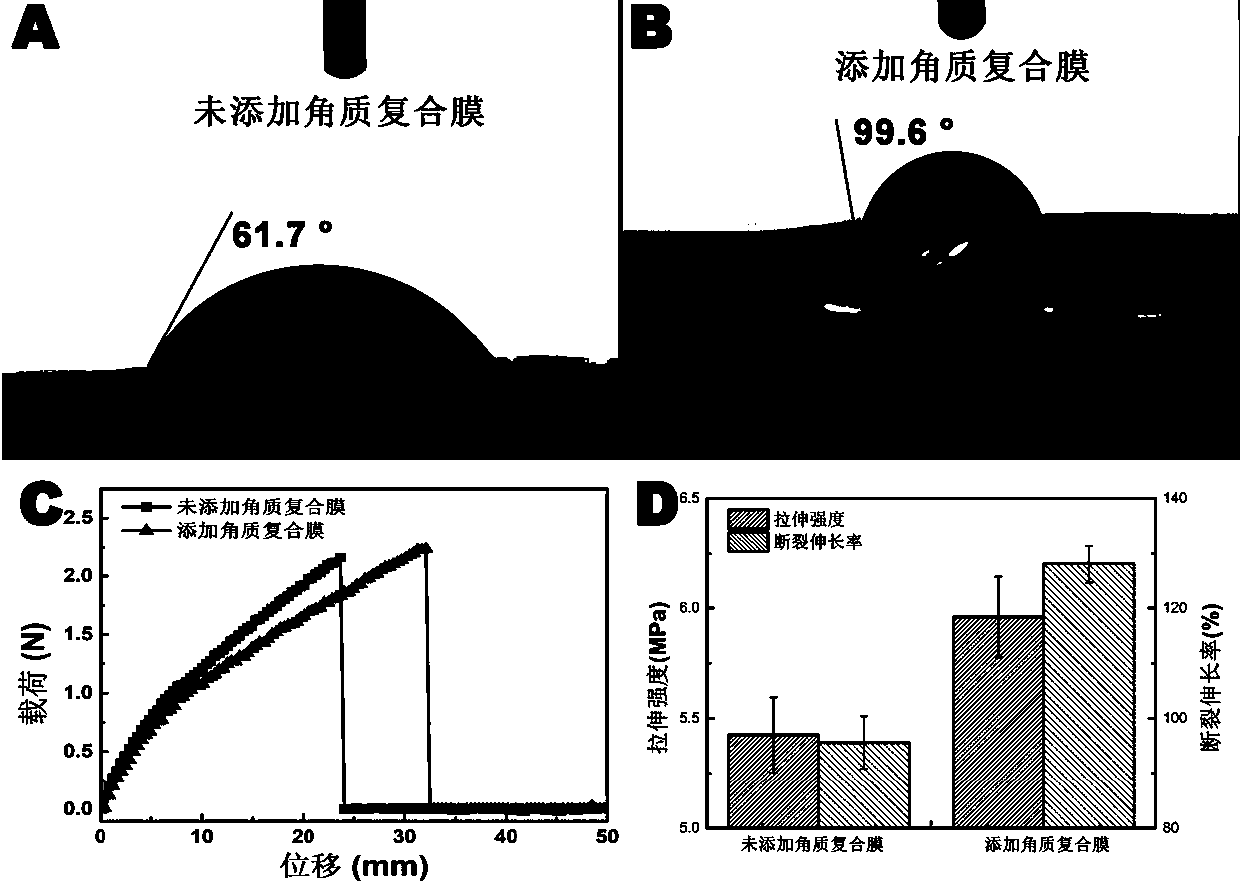

A food packaging film, hydrophobic type technology, applied in the field of hydrophobic food preservation film and its preparation, can solve the problems of easy water absorption, mechanical properties, deterioration, etc., achieve good biocompatibility and degradability, freshness preservation performance, and enhance hydrophobicity Performance, enhanced toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention also provides a method for extracting the lotus leaf cutin and a method for preparing a hydrophobic food preservation film, including the following steps:

[0052] 1) Put 200-300 portions of fresh lotus leaves in a blast oven and dry. Use a powdering machine to crush the lotus leaf and sieve to obtain 80-100 mesh lotus leaf powder;

[0053] 2) Disperse 50-60 parts of dried lotus leaf powder in 500 parts of water, add 2-3 parts of pectinase and 1-2 parts of cellulase, and then ultrasonically shake in an ultrasonic disperser for 10-20 minutes, and then Place it in a water bath at 35-40 ℃ and heat for 48 hours to enzymolyze pectin and cellulose to promote the dispersion of lotus leaf powder;

[0054] 3) Add NaOH powder to the above suspension, adjust its pH to 12-14, then place it in an ultrasonic disperser and sonicate for 10 minutes to remove air from the liquid, and pour the suspension into polytetrafluoroethylene In the reactor, use high-purity nitrogen to pur...

Embodiment 1

[0063] A hydrophobic food fresh-keeping film, which is prepared from the following parts by weight of raw materials:

[0064] 20 parts of low methoxy pectin (degree of methyl esterification is 20-30%);

[0065] 20 parts of chitosan;

[0066] 10 parts of glycerin;

[0067] 3 parts acetic acid

[0068] 15 lotus leaf cutin

[0069] Furthermore, the extraction of the cutin of the lotus leaf involves the following raw materials:

[0070] 300 servings of fresh lotus leaves

[0071] Pectinase 2 parts

[0072] Cellulase 2 parts

[0073] The invention also provides a method for extracting the lotus leaf cutin and a method for preparing a hydrophobic food preservation film, including the following steps:

[0074] 1) Put 300 portions of fresh lotus leaves in a blast oven and dry. Use a powdering machine to crush the lotus leaf and sieve to obtain 80-100 mesh lotus leaf powder;

[0075] 2) Disperse 50 parts of dried lotus leaf powder in 500 parts of water, add 2 parts of pectinase and 2 parts of cellulas...

Embodiment 2

[0085] A hydrophobic food fresh-keeping film, which is prepared from the following parts by weight of raw materials:

[0086] 20 parts of low methoxy pectin (degree of methyl esterification is 20-30%);

[0087] 20 parts of chitosan;

[0088] 5 parts of glycerin;

[0089] 3 parts acetic acid

[0090] 15 lotus leaf cutin

[0091] Furthermore, the extraction of the cutin of the lotus leaf involves the following raw materials:

[0092] 300 servings of fresh lotus leaves

[0093] Pectinase 2 parts

[0094] Cellulase 2 parts

[0095] The specific preparation method is the same as in Example 1. In this example, the amount of glycerin added is relatively low, and the tensile strength of the composite film is high, but the toughness is poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com