Stamping mold and stamping method

A stamping die and internal pressure technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the inner wall and the outer wall are difficult to achieve simultaneous coverage, the quality of the forming is difficult to guarantee, and the forming process is cumbersome. Avoid deformation, Reduce molding process and improve molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing.

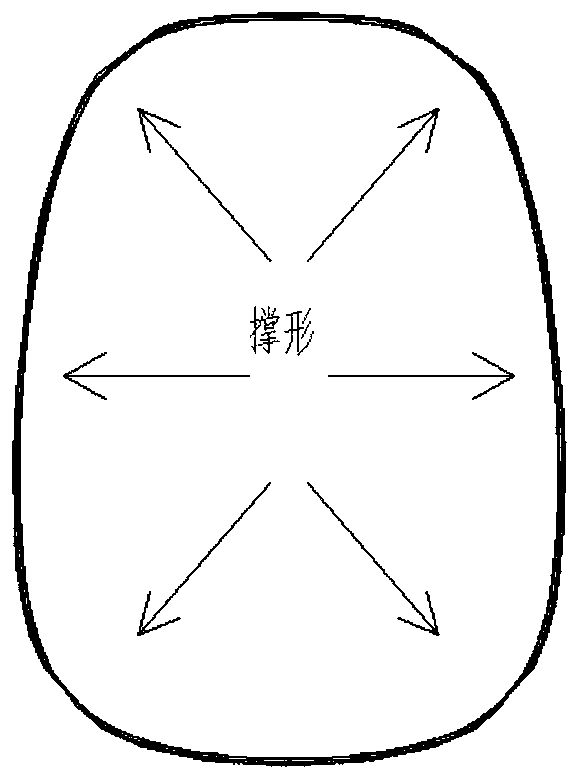

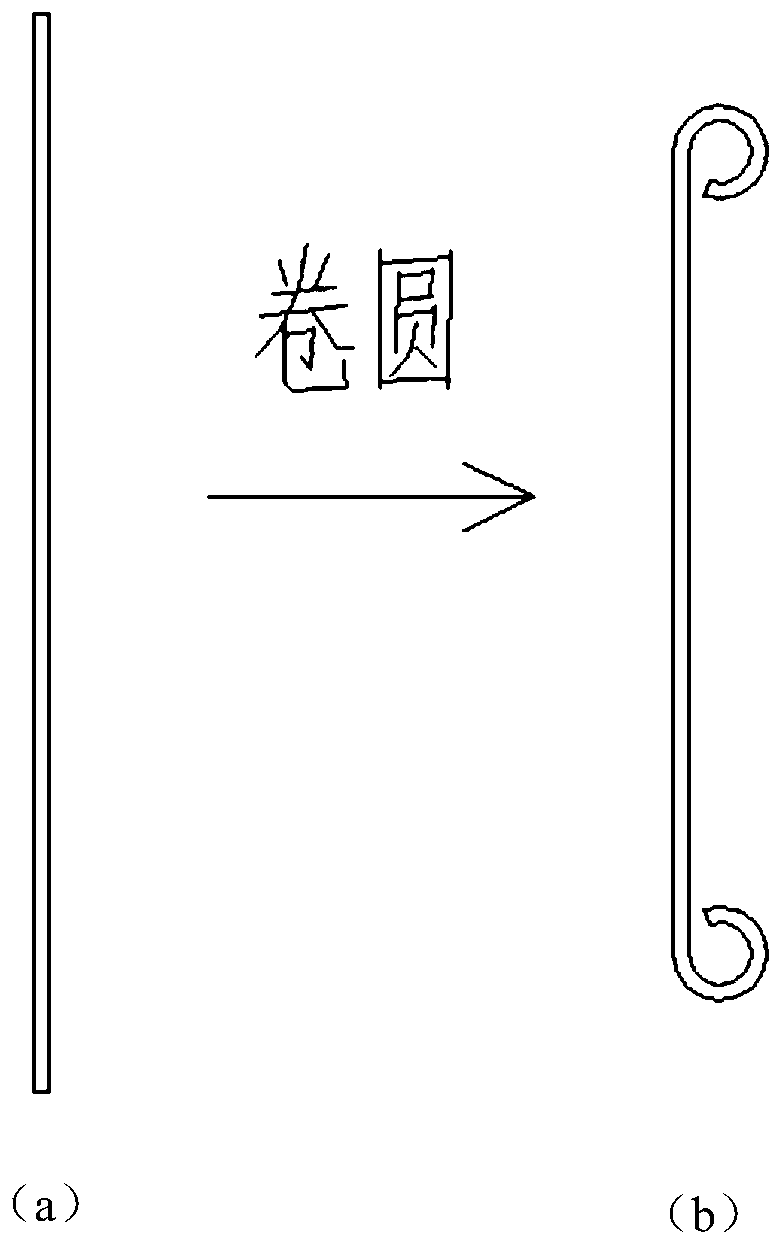

[0054] Such as Figure 4-8 As shown, according to the first aspect of the present invention, the present invention provides a stamping die, which includes an outer pressing mechanism 100 , an inner pressing mechanism 200 and a forming mechanism 300 . During stamping, the outer pressing mechanism 100 fits and presses the outer wall of the raw material, and the inner pressing mechanism 200 fits and presses the inner wall of the raw material, thereby pressing the outer wall and the inner wall of the raw material at the same time to realize the fixed support shape of the raw material; Then, the end of the raw material is punched and formed by the forming mechanism 300 .

[0055] Specifically, the outer pressing mechanism 100 includes an outer slider 101, and the outer sliding block 101 can move toward or away from the outer wall of the raw material 400 to squeeze or release the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com