Multipurpose tobacco leaf bulk curing barn

A technology of dense baking and dense curing rooms, applied in the fields of application, tobacco, and tobacco preparation, can solve problems such as single function, low utilization rate, and long idle time, so as to ensure the quality of baking, improve the utilization rate, and pack tobacco under baked simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

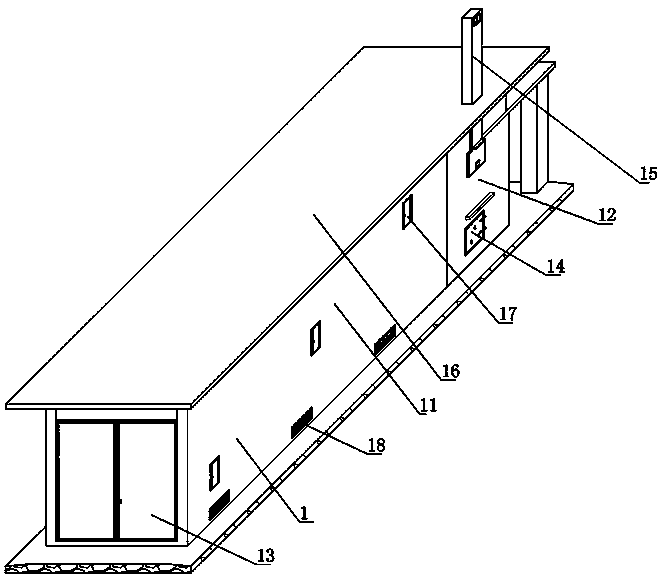

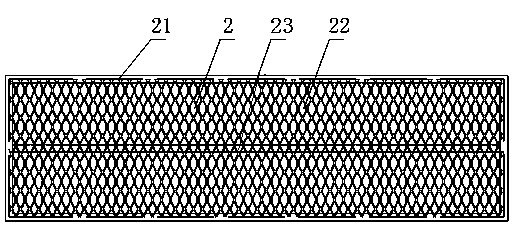

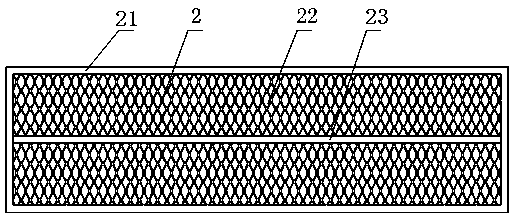

[0033] A multi-purpose tobacco leaf intensive curing room, which is composed of a descending airflow intensive curing room 1, a metal air distribution net 2, an H-shaped foldable composite square bar 3, and a bar fixing device 4, wherein:

[0034]The air flow descending dense barn 1 is composed of a smoke chamber 11 and a heating chamber 12. The heating chamber 12 includes a wall 1, a roof 16, a chimney 15, and return air outlets 1-2. In the heating chamber 12, a heating furnace 14, Radiator 1-5 and fan motor 19; smoke chamber 11 includes wall 1, roof 16, cigarette rack 1-1, smoke chamber door 13, observation window 17, air outlet 1-4, return air outlet 1- 2. The moisture outlet 18 is equipped with a cigarette hanging rack 1-1 in the smoke chamber 11 for hanging the tobacco leaves 5. Between the smoke chamber 11 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com