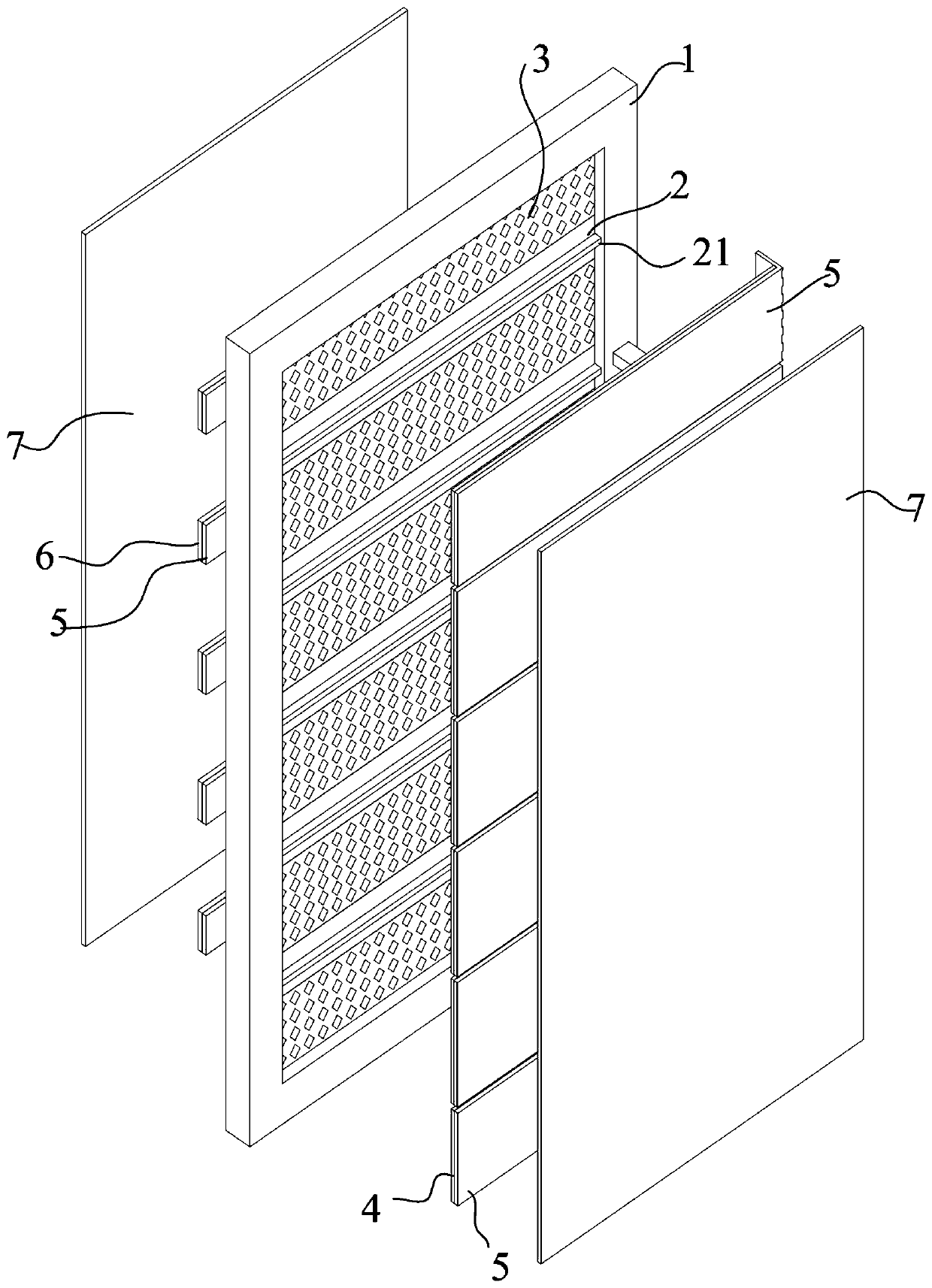

Novel plate-inserting type anti-radiation door and manufacturing method thereof

A radiation-proof, plug-in type technology, applied in the field of medical doors, can solve the problems of long production cycle, high atomic number and density of lead, and heavy weight of radiation-proof doors, and achieve weight reduction, shortened processing time, and convenient processing and transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0037] Embodiment 2, this embodiment provides the preparation method of the above-mentioned novel plug-in type radiation protection door

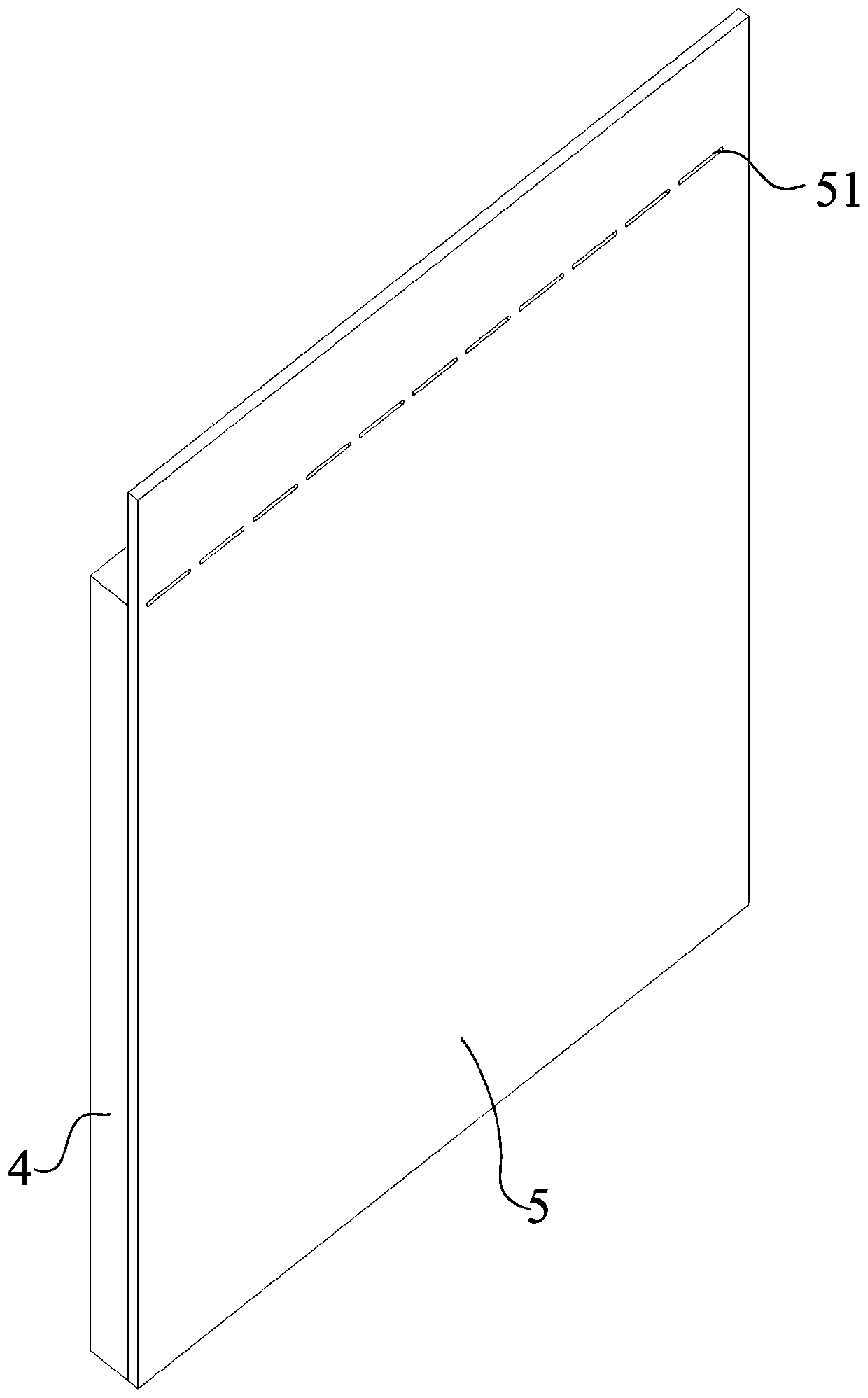

[0038] First, the lead plate 4 and the fixed steel plate 5 and the auxiliary lead plate 5 and the fixed steel plate 5 are bonded together for use. In this step, the three sides of the lead plate 4 and the fixed steel plate 5 are aligned, and one side of the fixed steel plate 5 is aligned. The length is greater than the length of the lead plate 4. At the same time, a slot hole is punched at the position where the edge is aligned with the lead plate. The purpose of this setting is mainly to consider that when the lead plate is inserted into the cavity in the later stage, the way of gluing is adopted. In order to ensure Fixed fastness, in this way, the fixed steel plate 5 can be bent and then fixed with screws to improve the stabilizing effect.

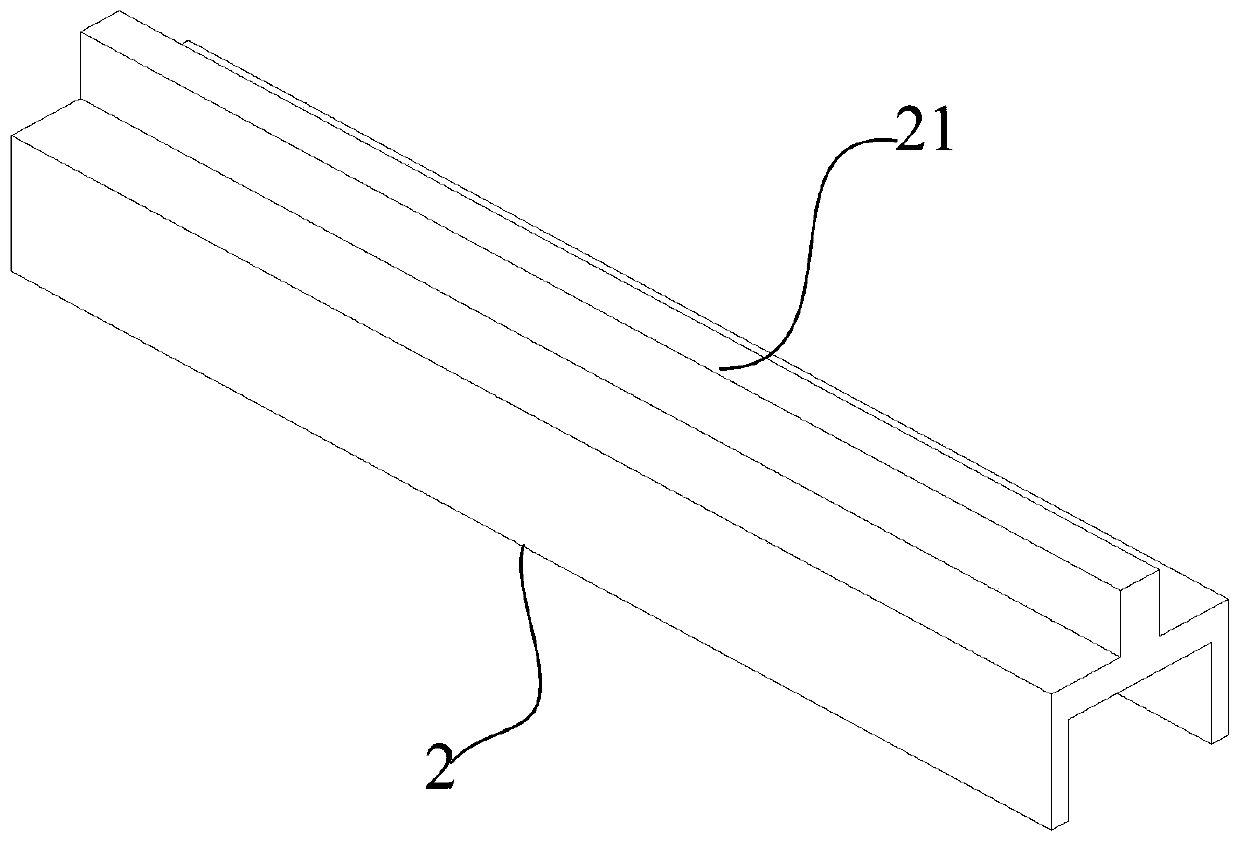

[0039] Then, the aluminum plate is extruded into a shape in which the split keel and the insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com