Structure with prestress assembly type concrete frame-energy consumption support reinforcement arranged outside existing structure

An energy-consuming support and existing structure technology, applied in building components, building structures, protective buildings/shelters, etc., can solve problems such as complicated and lengthy construction periods, difficult construction quality guarantees, and insufficient earthquake resistance, and achieve Improve construction efficiency and reinforcement quality, improve stress state and deformation mode, and enhance the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A detailed description will be given below in conjunction with the embodiments.

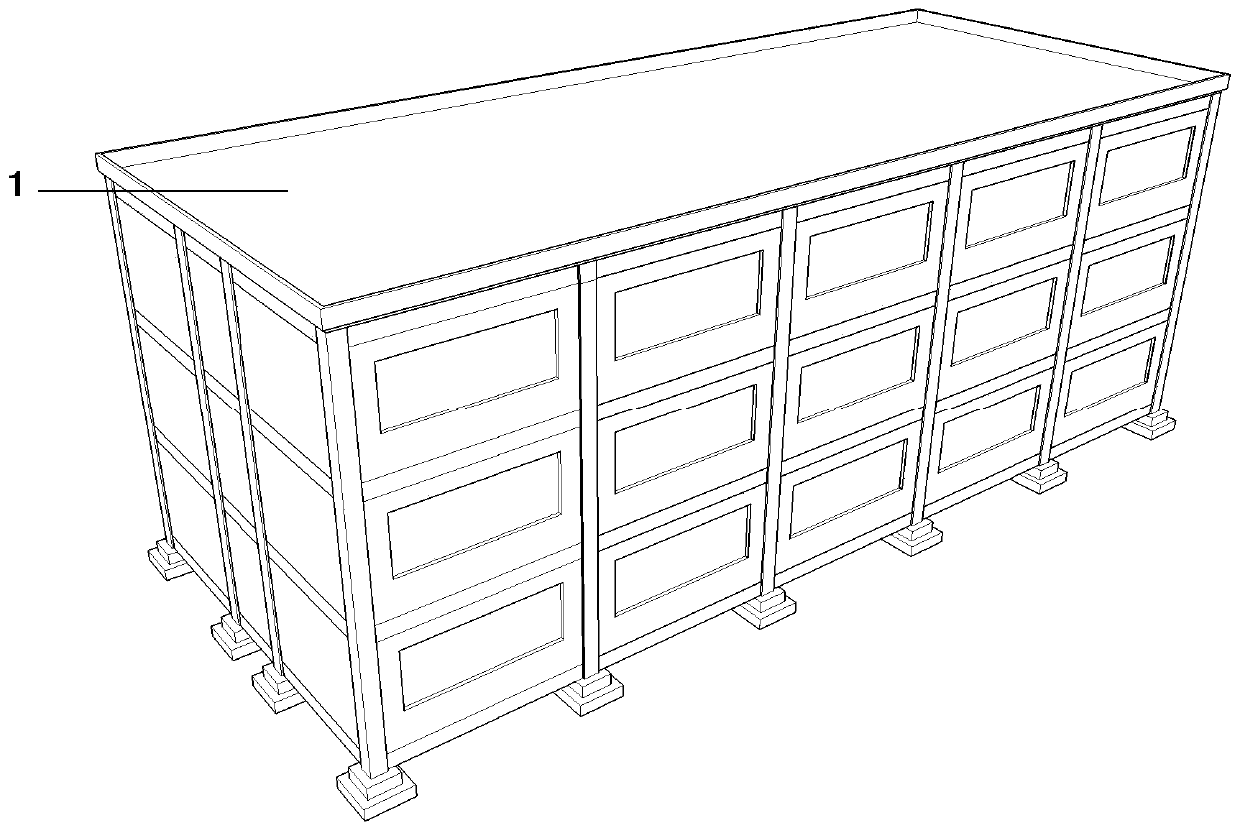

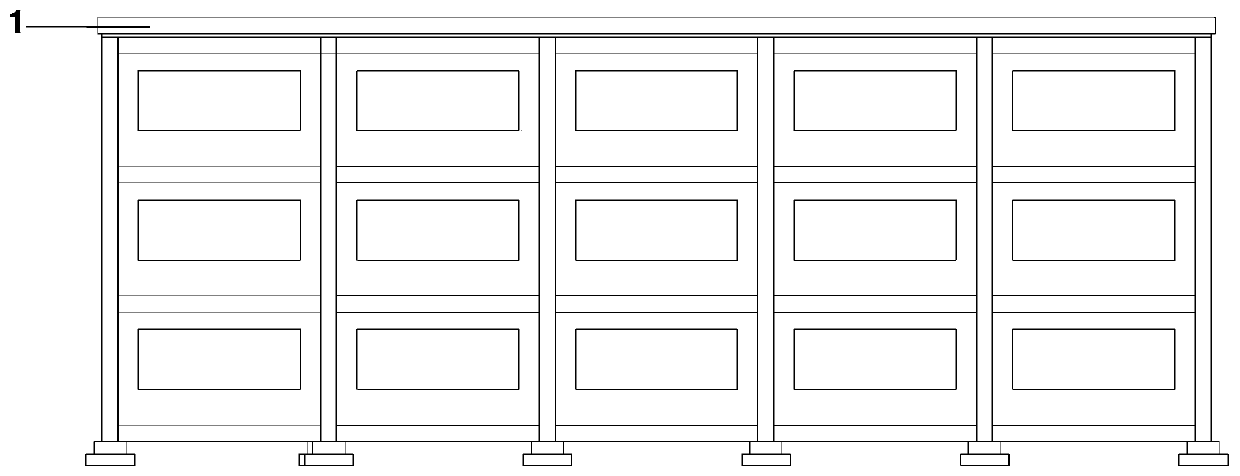

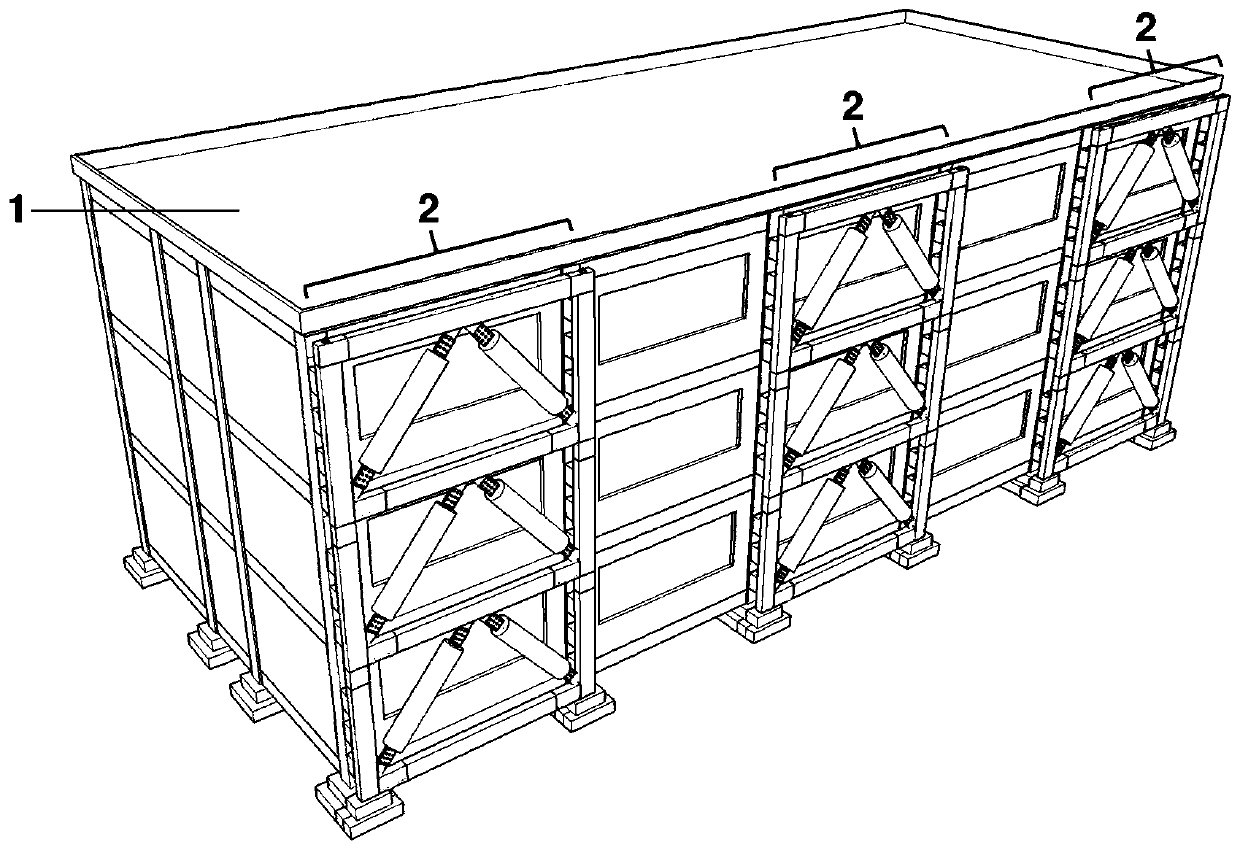

[0052] Such as Figure 1-7 As shown, the existing structure of the present invention is equipped with a prestressed assembled concrete frame-energy-dissipating support reinforcement structure including an external frame-energy-dissipating support structure 2 fixed on the outer surface of the original structure 1 to be reinforced. - The energy-dissipating support structure 2 is divided into three groups and fixed on the original structure 1 at equal intervals.

[0053] The external frame-energy-dissipating support structure 2 includes prefabricated beams 3, prefabricated columns 4, and prefabricated supports 5. The prefabricated beams 3 and prefabricated columns 4 are fixedly connected to each other, and concrete is poured at the connection nodes to form an external frame-energy-dissipating support structure. An external frame; the prefabricated columns 4 which are fixedly connected in tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com