A wood-plastic composite material based on lignin and coffee shell powder and its preparation method

A wood-plastic composite material and lignin technology, which is applied in the field of wood-plastic composite materials, can solve the problems of poor performance of wood-plastic composite materials, achieve the effects of alleviating the large amount of plastic used, improving the impact strength, and alleviating the shortage of forest resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

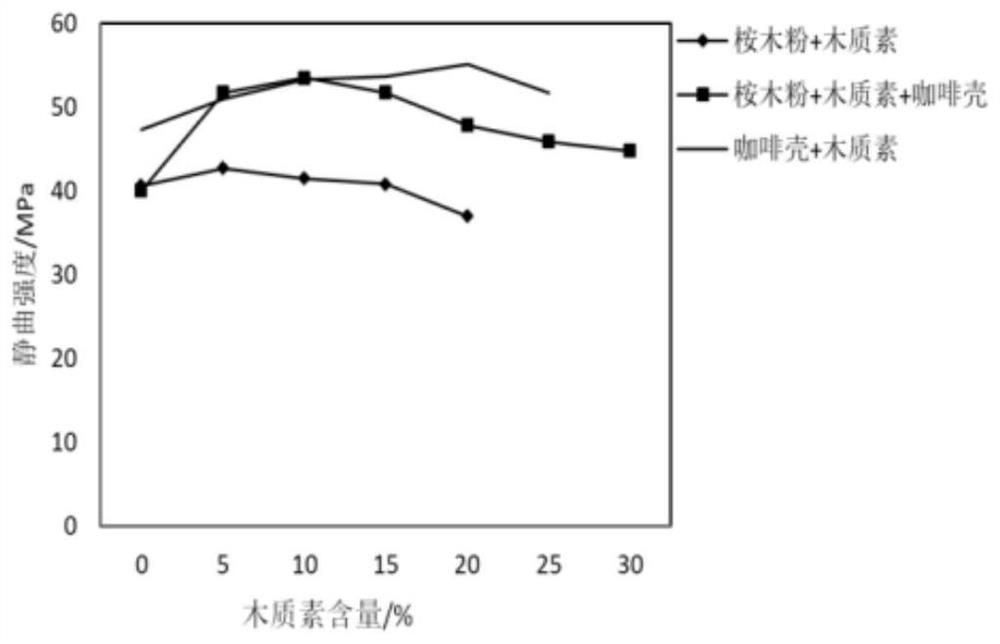

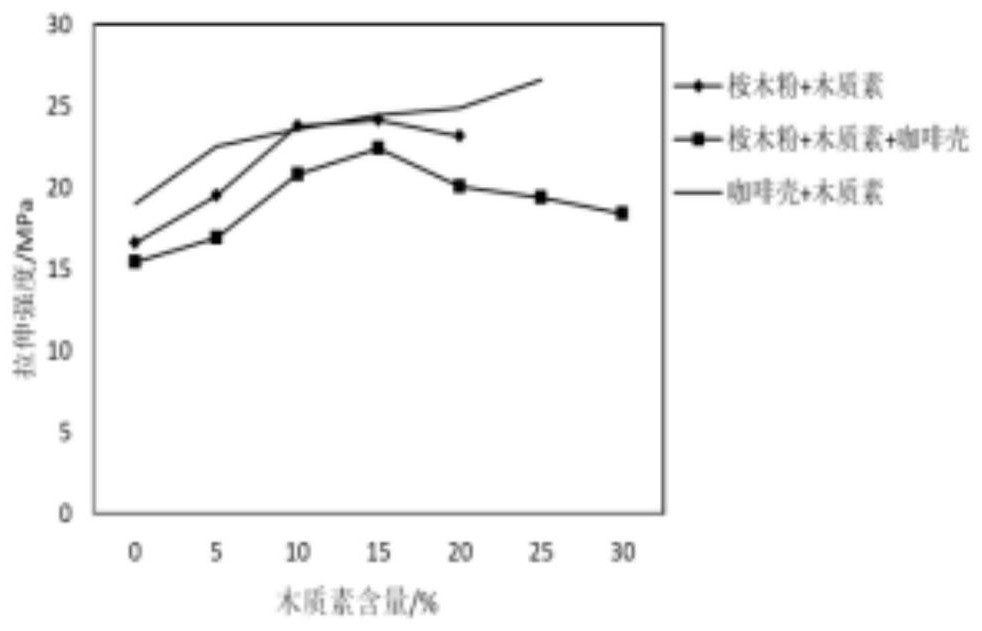

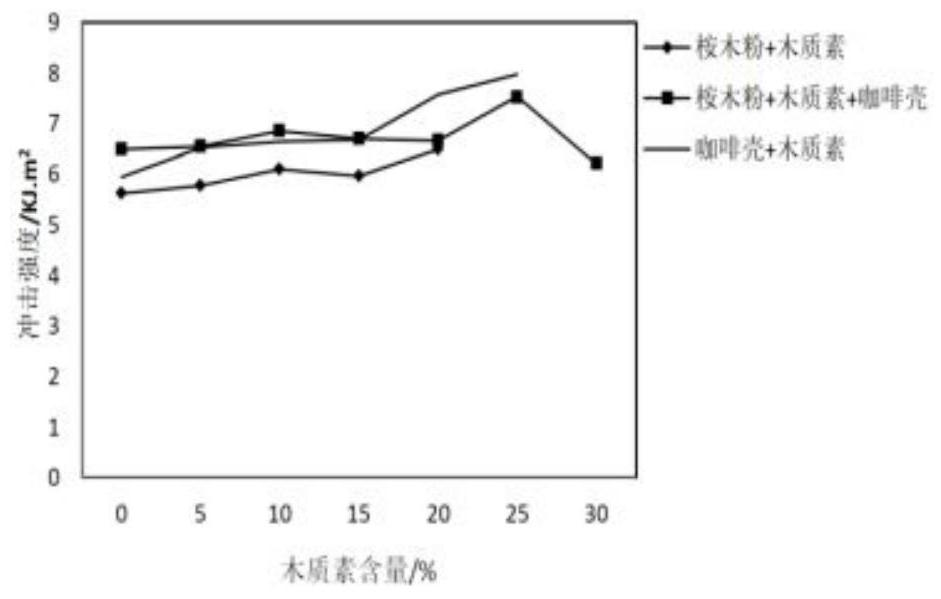

Image

Examples

Embodiment 1

[0037] The wood-plastic composite material based on lignin and coffee husk powder of this embodiment includes the following raw materials in mass percentage:

[0038] 25% lignin, 5% coffee shell powder, 30% wood powder, density 0.90-0.96g / cm 3 20% polyethylene, 10% maleic anhydride grafted polyethylene, 8% calcium carbonate, 1% paraffin, 1% dispersant (0.5% each of stearic acid and calcium stearate).

[0039] The preparation method of the above-mentioned wood-plastic composite material that this embodiment also relates to is carried out as follows:

[0040] Firstly, the lignin was dried at 60°C for 24 hours, and the coffee shell powder and wood powder were dried in a blast drying oven at 105°C for 4 hours. Then mix lignin, coffee shell powder, wood powder, polyethylene, compatibilizer, filler, lubricant and dispersant in a high-speed mixer according to the above ratio for 20 minutes at a speed of 1000r / min; melt in a twin-screw extruder For mixing, the temperatures in Zone 1...

Embodiment 2

[0043] The wood-plastic composite material based on lignin and coffee husk powder of this embodiment includes the following raw materials in mass percentage:

[0044] 20% lignin, 10% coffee shell powder, 30% wood powder, density 0.90-0.96g / cm 3 20% polyethylene, 10% maleic anhydride grafted polyethylene, 8% calcium carbonate, 1% paraffin, 1% dispersant (0.5% each of stearic acid and calcium stearate).

[0045] The preparation method of the above-mentioned wood-plastic composite material that this embodiment also relates to is carried out as follows:

[0046]Firstly, the lignin was dried at 60°C for 24 hours, and the coffee shell powder and wood powder were dried in a blast drying oven at 105°C for 4 hours. Then mix lignin, coffee shell powder, wood powder, polyethylene, compatibilizer, filler, lubricant and dispersant in a high-speed mixer according to the above ratio for 20 minutes at a speed of 1000r / min; melt in a twin-screw extruder For mixing, the temperatures in Zone 1...

Embodiment 3

[0049] The wood-plastic composite material based on lignin and coffee husk powder of this embodiment includes the following raw materials in mass percentage:

[0050] 15% lignin, 15% coffee shell powder, 30% wood powder, density 0.90-0.96g / cm 3 25% polyethylene, 5% maleic anhydride grafted polyethylene, 8% calcium carbonate, 1% paraffin, 1% dispersant (0.5% each of stearic acid and calcium stearate).

[0051] The preparation method of the above-mentioned wood-plastic composite material that this embodiment also relates to is carried out as follows:

[0052] Firstly, the lignin was dried at 55°C for 24 hours, and the coffee shell powder and wood powder were dried in a blast drying oven at 105°C for 4 hours. Then mix lignin, coffee shell powder, wood powder, polyethylene, compatibilizer, filler, lubricant and dispersant in a high-speed mixer according to the above ratio for 20 minutes at a speed of 1000r / min; melt in a twin-screw extruder For mixing, the temperatures in Zone 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com