Self-stabilizing polyvinyl chloride resin preparation method

A polyvinyl chloride resin and self-stabilizing technology, which is applied in the field of self-stabilizing polyvinyl chloride resin and its preparation, can solve the problems of adding organic tin environmental protection heat stabilizers and other problems, so as to avoid changes in polymer properties, slow down dehydrochlorination, The effect of delaying the generation of free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

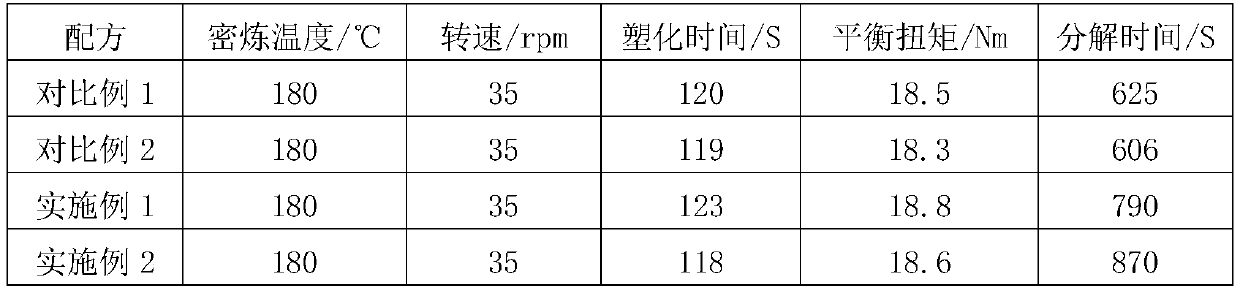

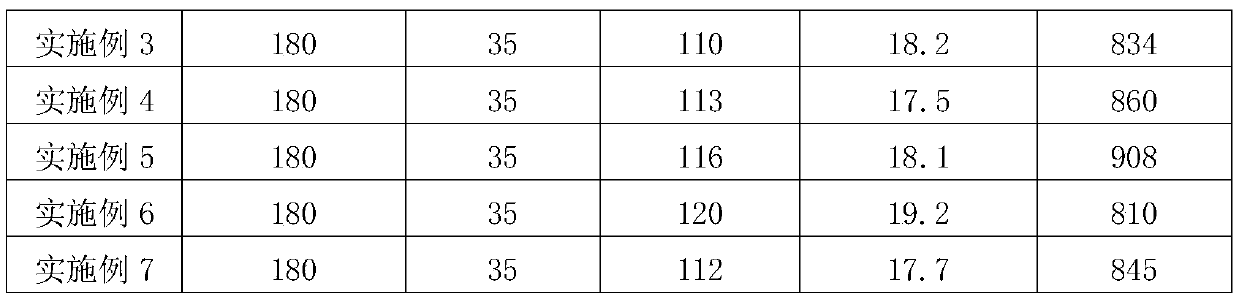

Examples

Embodiment 1

[0030] Get the production raw material of following weight part: Deionized water: 160 parts; Vinyl chloride: 100 parts; Main dispersant: 0.016 part; Auxiliary dispersant: 0.005 part; Antioxidant: 0.006 part; pH regulator: 0.006 part; Terminator: 0.015 part.

[0031] The main dispersant is composed of two kinds of polyvinyl alcohol and hydroxypropyl methylcellulose with different degrees of alcoholysis, that is, 0.008 parts of KH-20 with a degree of alcoholysis of 81, 0.004 parts of L-10 with a degree of alcoholysis of 72, Composed of 0.004 parts F-50 hydroxypropyl methylcellulose. The auxiliary dispersant is 0.005 parts of polyvinyl alcohol LL-02 with an alcoholysis degree of 50. The composite initiator is composed of 0.008 parts of di(2-ethyl)hexyl peroxydicarbonate and 0.004 parts of cumyl peroxyneodecanoate. The pH regulator is ammonium bicarbonate, and the addition amount is 0.006 parts. The composite terminator consists of 0.006 parts of N,N-diethylhydroxylamine, 0.006...

Embodiment 2

[0034] Get the production raw material of following weight part: Deionized water: 160 parts; Vinyl chloride: 100 parts; Main dispersant: 0.016 part; Auxiliary dispersant: 0.005 part; Antioxidant: 0.006 part; pH regulator: 0.006 part; Terminator: 0.015 part.

[0035] The main dispersant is composed of two kinds of polyvinyl alcohol and hydroxypropyl methylcellulose with different degrees of alcoholysis, that is, 0.008 parts of KH-20 with a degree of alcoholysis of 81, 0.004 parts of L-10 with a degree of alcoholysis of 72, Composed of 0.004 parts F-50 hydroxypropyl methylcellulose. The auxiliary dispersant is 0.005 parts of polyvinyl alcohol LL-02 with an alcoholysis degree of 50. The composite initiator is composed of 0.008 parts of di(2-ethyl)hexyl peroxydicarbonate and 0.004 parts of cumyl peroxyneodecanoate. The pH regulator is ammonium bicarbonate, and the addition amount is 0.006 parts. The composite terminator consists of 0.006 parts of N,N-diethylhydroxylamine, 0.006...

Embodiment 3

[0038] Get the production raw material of following weight part: Deionized water: 160 parts; Vinyl chloride: 100 parts; Main dispersant: 0.016 part; Auxiliary dispersant: 0.005 part; Antioxidant: 0.006 part; pH regulator: 0.006 part; Terminator: 0.015 part.

[0039] The main dispersant is composed of two kinds of polyvinyl alcohol and hydroxypropyl methylcellulose with different degrees of alcoholysis, that is, 0.008 parts of KH-20 with a degree of alcoholysis of 81, 0.004 parts of L-10 with a degree of alcoholysis of 72, Composed of 0.004 parts F-50 hydroxypropyl methylcellulose. The auxiliary dispersant is 0.005 parts of polyvinyl alcohol LL-02 with an alcoholysis degree of 50. The composite initiator is composed of 0.008 parts of di(2-ethyl)hexyl peroxydicarbonate and 0.004 parts of cumyl peroxyneodecanoate. The pH regulator is ammonium bicarbonate, and the addition amount is 0.006 parts. The composite terminator consists of 0.006 parts of N,N-diethylhydroxylamine, 0.006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com