Preparation method of L-selenomethionine

A technology of selenomethionine and dimethyl sulfate, which is applied in the field of preparation of L-selenomethionine, can solve the problems that are not conducive to labor protection and environmental protection, have foul-smelling selenium-methanol gas, and are not environmentally friendly, so as to achieve the benefit of labor Conservation and environmental protection, mild conditions, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

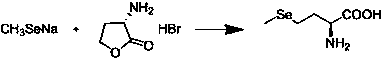

[0020] The invention provides a method for preparing L-selenomethionine. Compound 1 and compound 2 react to form compound 3. Compound 3 is reduced by sodium borohydride and then reacted with dimethyl sulfate to obtain the final product L-selenomethionine. . The synthetic route is .

[0021] The method of the present invention comprises two steps of step A and step B.

[0022] Step A, react compound 1 and compound 2 in a solvent, filter after reaction to obtain green solid compound 3, wherein the solvent is water, ethanol or methanol, the reaction temperature is 0-60°C (preferably 20-40°C), and the reaction The time is 3-10 hours (preferably 4-6 hours).

[0023] Compound 1 is , Compound 2 is , compound 3 is .

[0024] The molar ratio of compound 1 and compound 2 is 1:0.8-4, preferably 1:0.9-2.

[0025] This step specifically includes:

[0026] Preparation of compound 1: add sodium hydroxide to water at room temperature, add selenium particles after the sodium hydro...

Embodiment 1

[0029] Add sodium hydroxide (4.0 g, 0.1 mol) into water (30 ml) at room temperature, add selenium particles (7.9 g, 0.1 mol) after the sodium hydroxide is completely dissolved, and then add hydrazine hydrate (6.4 g, 0.1 mol) dropwise ), the dropwise addition was completed, and the temperature was slowly raised to 35°C for 3 hours, under nitrogen protection, compound 2 [(26.3g, 0.1mol) dissolved in 60ml of water] was added dropwise at this temperature, and reacted at 35°C for 3 hours after the dropwise addition was completed. After the reaction was completed, the temperature of the reaction system was lowered to 5° C., suction filtered, and dried to obtain 18.76 g of a green solid with a crude yield of 79.8% and an HPLC purity of 95%.

Embodiment 2

[0031] Add sodium hydroxide (4.0 g, 0.1 mol) into ethanol (30 ml) at room temperature, add selenium particles (7.9 g, 0.1 mol) after the sodium hydroxide is completely dissolved, and then add hydrazine hydrate (6.4 g, 0.1 mol) dropwise ), the dropwise addition was completed, and the temperature was slowly raised to 40°C for 3 hours, protected by nitrogen, and compound 2 [(23.7g, 0.09mol) dissolved in 60ml of ethanol] was added dropwise at this temperature, and reacted at 40°C for 4 hours after the dropwise addition was completed. After the reaction was completed, the temperature of the reaction system was lowered to 5° C., suction filtered, and dried to obtain 20.6 g of a green solid, with a crude product yield of 60.4% and an HPLC purity of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com