Refractory ramming mass for hot metal ladle of ferrosilicon electric furnace and preparation method for refractory ramming mass

A technology of ramming material and electric furnace, which is applied in the field of refractory ramming material for ferrosilicon electric furnace ladle and its preparation, can solve the problems of personal and equipment safety hazards, serious molten iron sticking, low safety factor, etc. The effect of sufficient aggregate and enhanced material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

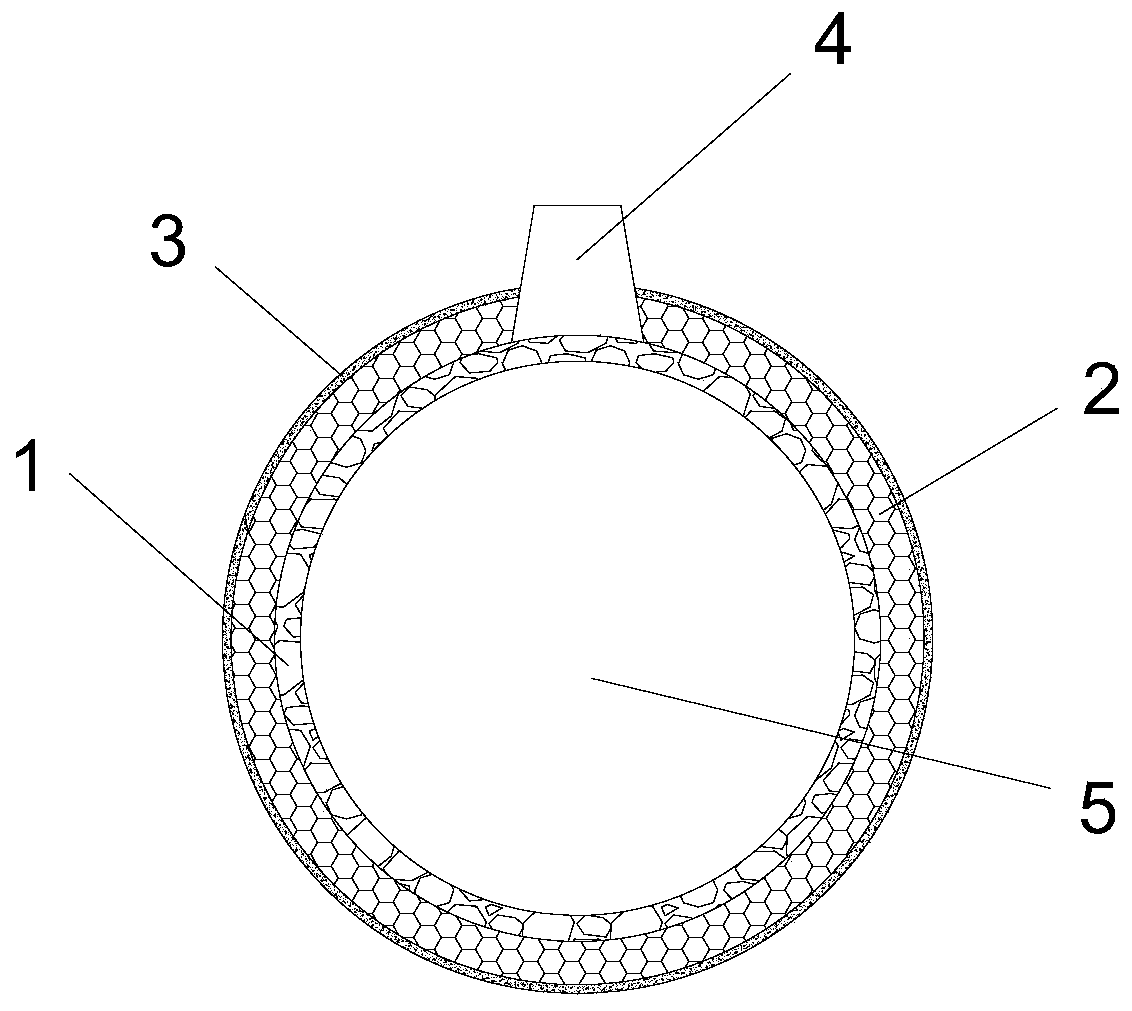

Image

Examples

Embodiment Construction

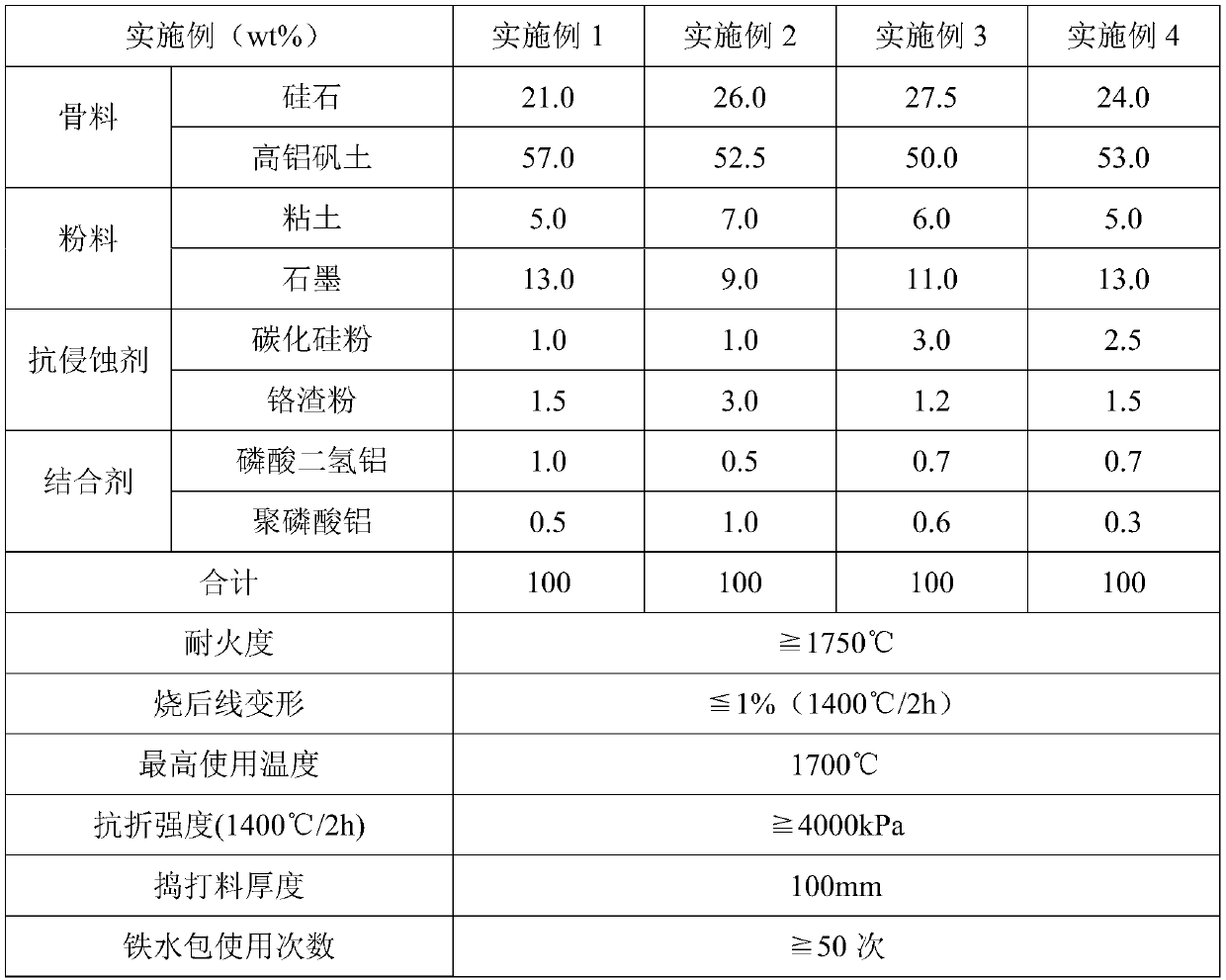

[0042] The following provides specific implementations of a refractory ramming material for a ferrosilicon electric furnace ladle of the present invention and a preparation method thereof, but the present invention is not limited to the provided examples.

[0043] The composition of raw materials in Examples 1-4 of the present invention is shown in Table 1;

[0044] The method for preparing the refractory ramming material for the iron ladle of the ferrosilicon electric furnace in the embodiment 1-4 of the present invention, the steps are:

[0045] (1) Weigh aluminum dihydrogen phosphate and aluminum polyphosphate by weight percentage, add 4 times the weight of water in a ratio of 1:4 by weight, and heat to 50°C and stir until aluminum dihydrogen phosphate and aluminum polyphosphate Dissolve all in water to form an additive solution;

[0046] (2) Weigh the clay, graphite, silicon carbide powder, and chromium slag powder according to weight percentages and pre-mix, then add silica and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com