Machine-sprayed thick-layer polymer repairing mortar and preparation method thereof

A repairing mortar and polymer technology, applied in the field of building materials, can solve the problem that the repairing mortar is difficult to meet the demand, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

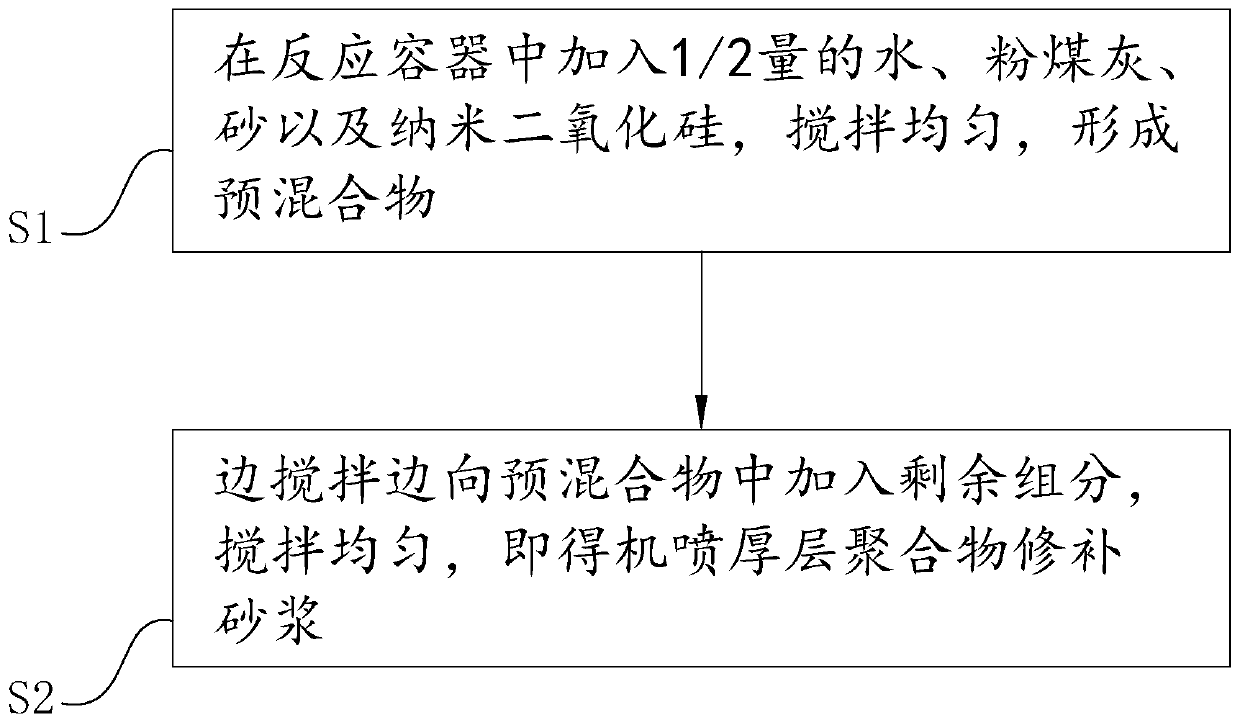

Method used

Image

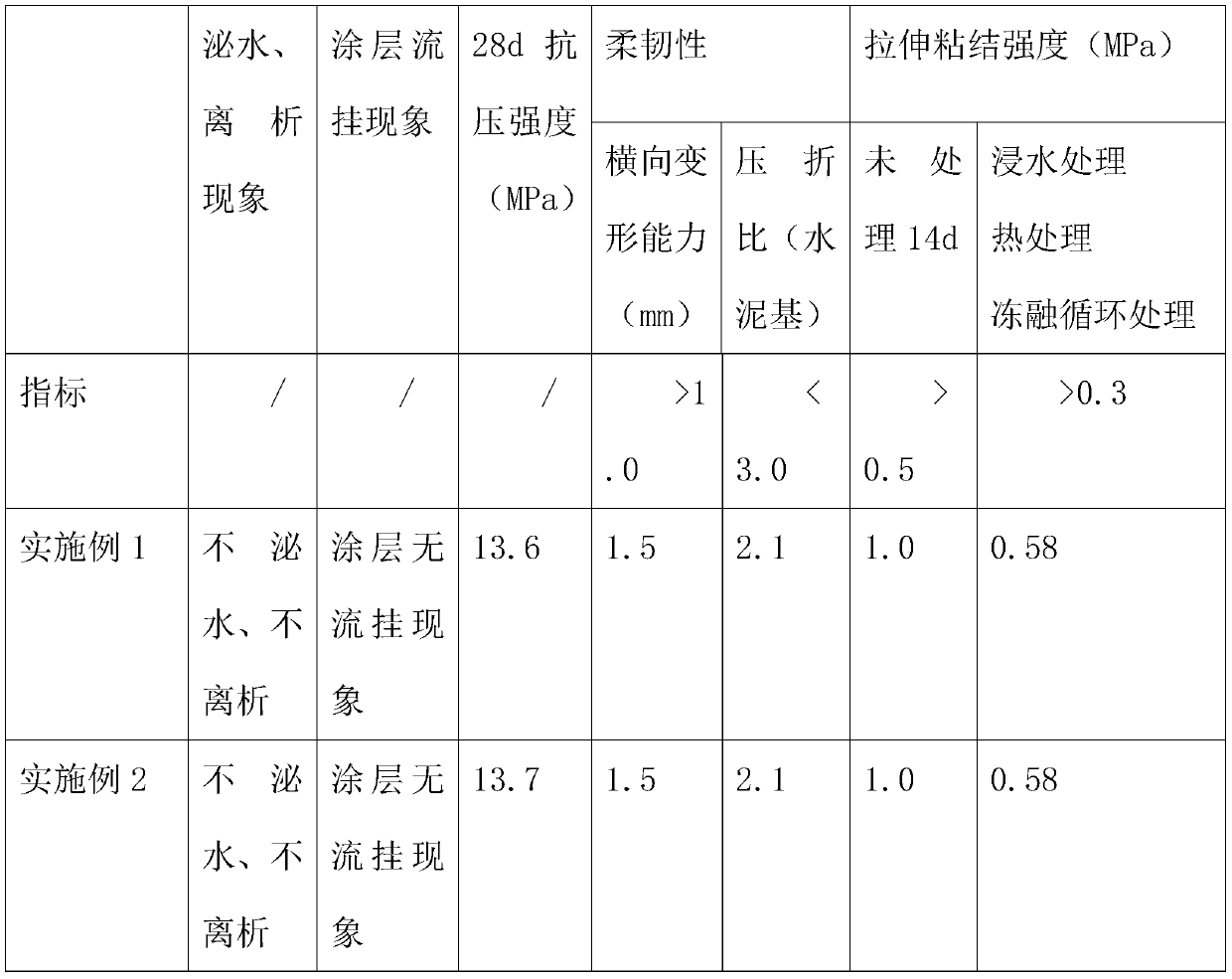

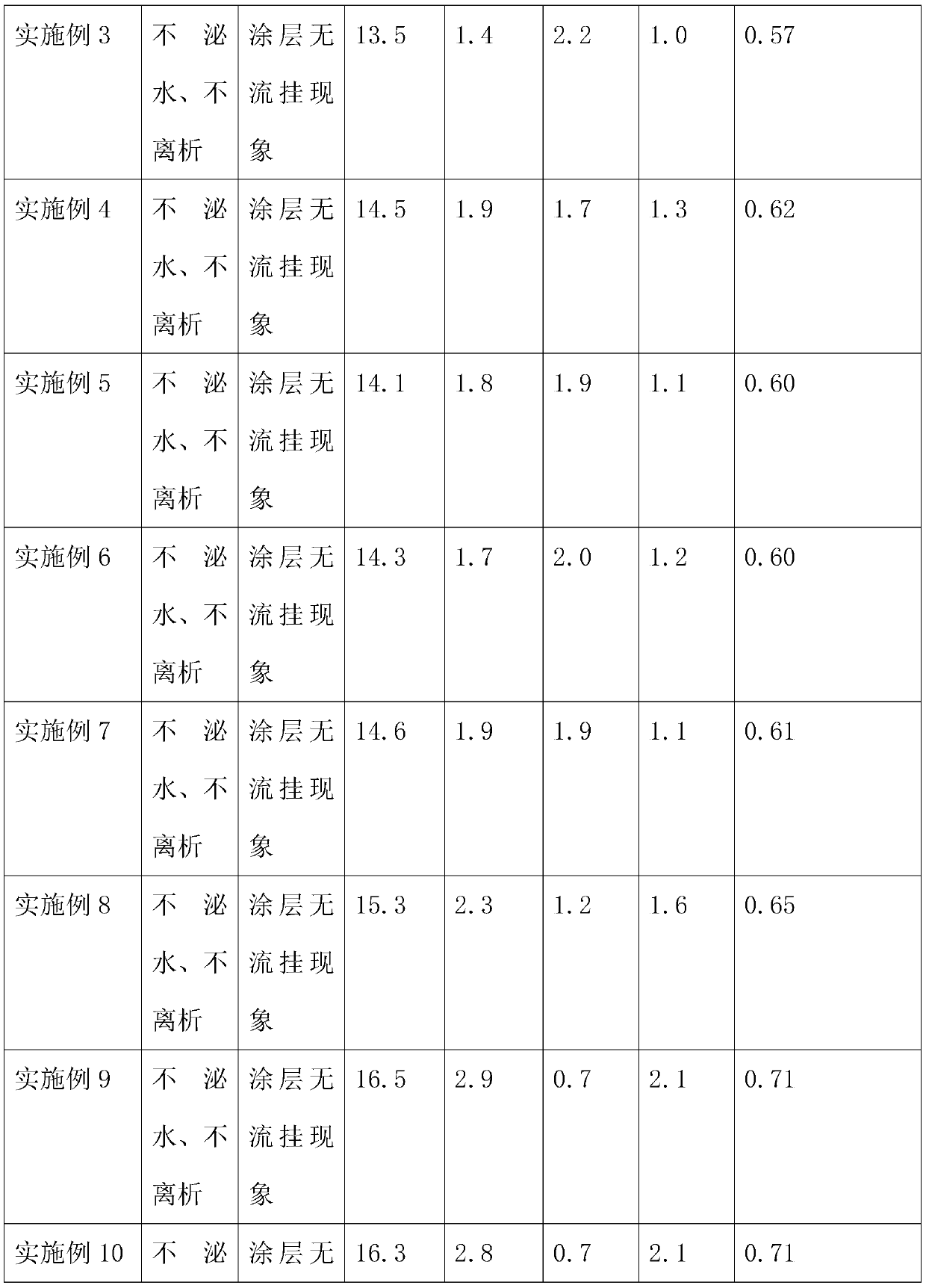

Examples

Embodiment 1

[0071] A machine-sprayed thick-layer polymer repair mortar, comprising the following components:

[0072] Portland cement 15kg; water 7kg; fly ash 10kg; sand 70kg; nano-silica 12kg; ethylene-vinyl acetate copolymer 3kg; Benzene anthracene 0.75kg.

[0073] In this embodiment, the sand consists of 28kg of continuously graded sand with a particle size of 0.15-0.6mm, 14kg of continuously graded sand with a particle size of 0.6-1.18mm, 14kg of continuously graded sand with a particle size of 1.18-2.36mm, and 14kg of continuously graded sand with a particle size of 0.6-1.18mm. It is made of 2.36-4.75mm continuous graded sand evenly mixed.

[0074] The preparation method of machine-sprayed thick-layer polymer non-repair mortar is as follows:

[0075] S1. In a 150L stirred tank, under normal temperature, stir at a speed of 250r / min. While stirring, add 3.5kg of water, 10kg of fly ash, 70kg of sand and 12kg of nano-silica, and stir evenly to form a premix;

[0076] S2. Add 15 kg of ...

Embodiment 2

[0078] A machine-sprayed thick-layer polymer repair mortar, comprising the following components:

[0079] Portland cement 12.5kg; water 5kg; fly ash 12kg; sand 73.5kg; nano silicon dioxide 10kg; ethylene-vinyl acetate copolymer 4kg; Biphenylanthracene 1kg.

[0080] In this embodiment, the sand consists of 29.4kg of continuously graded sand with a particle size of 0.15-0.6mm, 14.7kg of continuously graded sand with a particle size of 0.6-1.18mm, 14.7kg of continuously graded sand with a particle size of 1.18-2.36mm, and 14.7kg of continuously graded sand with a particle size of 2.36-4.75mm is uniformly mixed.

[0081] The preparation method of machine-sprayed thick-layer polymer non-repair mortar is as follows:

[0082] S1. In a 150L stirring tank, stir at a speed of 250r / min at room temperature, add 2.5kg of water, 12kg of fly ash, 73.5kg of sand and 10kg of nano-silica while stirring, and stir evenly to form a premix ;

[0083] S2. Add 12.5kg of Portland cement, 2.5kg of ...

Embodiment 3

[0085] A machine-sprayed thick-layer polymer repair mortar, comprising the following components:

[0086] Portland cement 10kg; water 6kg; fly ash 8kg; sand 77kg; nano-silica 11kg; ethylene-vinyl acetate copolymer 5kg; Anthracene 0.5kg.

[0087] In this embodiment, the sand consists of 30.8kg of continuously graded sand with a particle size of 0.15-0.6mm, 15.4kg of continuously graded sand with a particle size of 0.6-1.18mm, 15.4kg of continuously graded sand with a particle size of 1.18-2.36mm, and 15.4kg of continuously graded sand with a particle size of 2.36-4.75mm is uniformly mixed.

[0088] The preparation method of machine-sprayed thick-layer polymer non-repair mortar is as follows:

[0089] S1. In a 150L stirred tank, stir at a speed of 250r / min under normal temperature conditions, add 3kg of water, 8kg of fly ash, 77kg of sand and 11kg of nano silicon dioxide while stirring, and stir evenly to form a premixture;

[0090] S2. Add Portland cement 10kg, water 3kg, et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com