A new ultra-thin terminal lead for laminated components

A technology of laminated components and left-end leads, which is applied in the field of solar cell components, can solve the problems of increasing the cost of laminated components, low stamping efficiency, and slow speed, and achieve the effects of improving market competitiveness, improving stamping efficiency, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

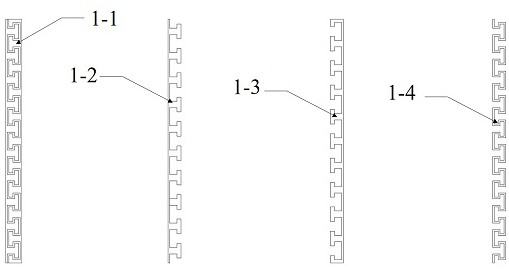

[0034] figure 1 It is the stamping design drawing of the ultra-thin end leads used in the lamination used in the embodiment, and the left end leads 1-2, the right end leads 1-3 and the stamping residue 1-4 are densely arranged on the ultra-thin substrate 1-1. In embodiment 1, the ultra-thin substrate 1-1 has a length of 150mm and a width of 10mm; after stamping, the left and right end leads 1-2 and 1-3 are 150mm long and 8mm wide; , the total length of the residual material is 290mm, and the proportion of the residual material to the substrate is 19.3%.

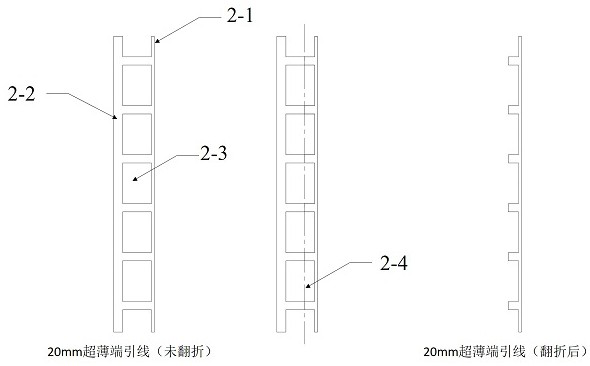

[0035] figure 2 It is the currently commonly used 20mm wide ultra-thin end lead stamping pattern. The pattern u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com