Cable combustion fire simulation system and method for full-size underground space

An underground space and simulation system technology, applied in teaching models, educational appliances, instruments, etc., can solve the problems of insufficient cable fire research and high difficulty in cable fire research, and achieve the effect of eliminating potential safety hazards and reducing economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

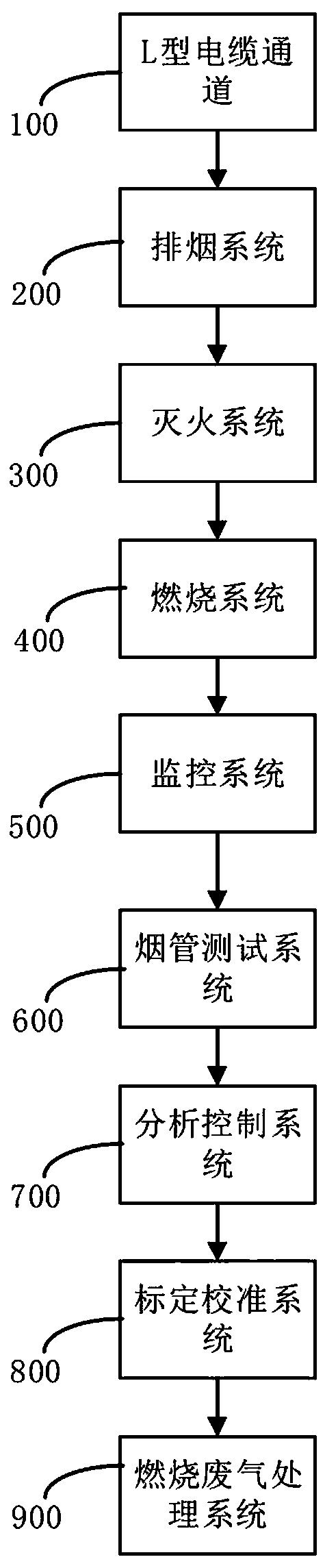

[0064] figure 1 It is a schematic diagram of the implementation flow of a full-scale underground space cable combustion fire simulation system and device provided by the embodiment of the present application. As shown in the figure, the method may include the following steps:

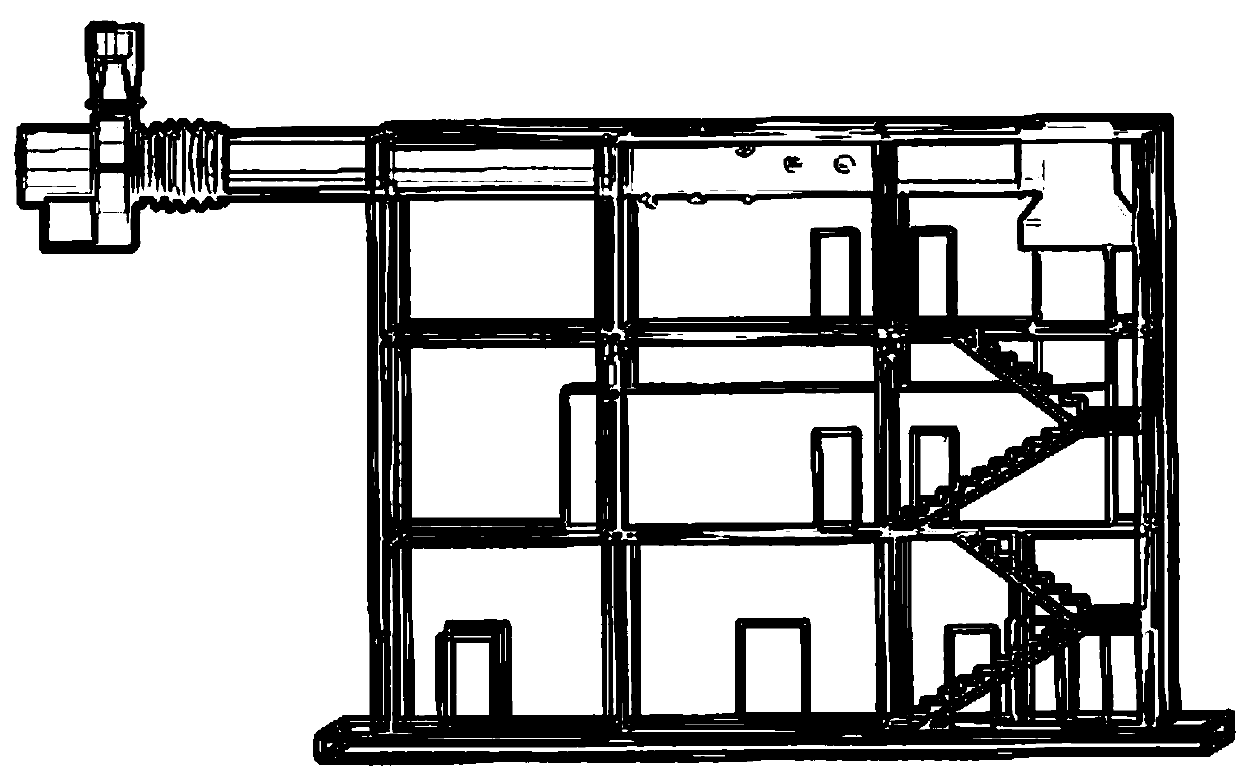

[0065] Step 1, the cable is mode-burned in the L-shaped cable channel. The L-shaped cable channel is the main part of the full-scale simulation analysis laboratory. It adopts a steel structure and is composed of a proportional size model of the L-shaped channel composed of a 2m horizontal channel and a 4m*2m*1m longitudinal channel. It is used in tunnels. Simulation of combustion conditions. The main structure of the channel is equipped with a fire-proof and heat-insulation system, and the thickness of the heat-insulation layer is required to be 300 mm, which can meet the fire resistance requirements of 1000 degrees Celsius and withstand 20 minutes. The L-shaped cable channel is also equipped with oth...

Embodiment 2

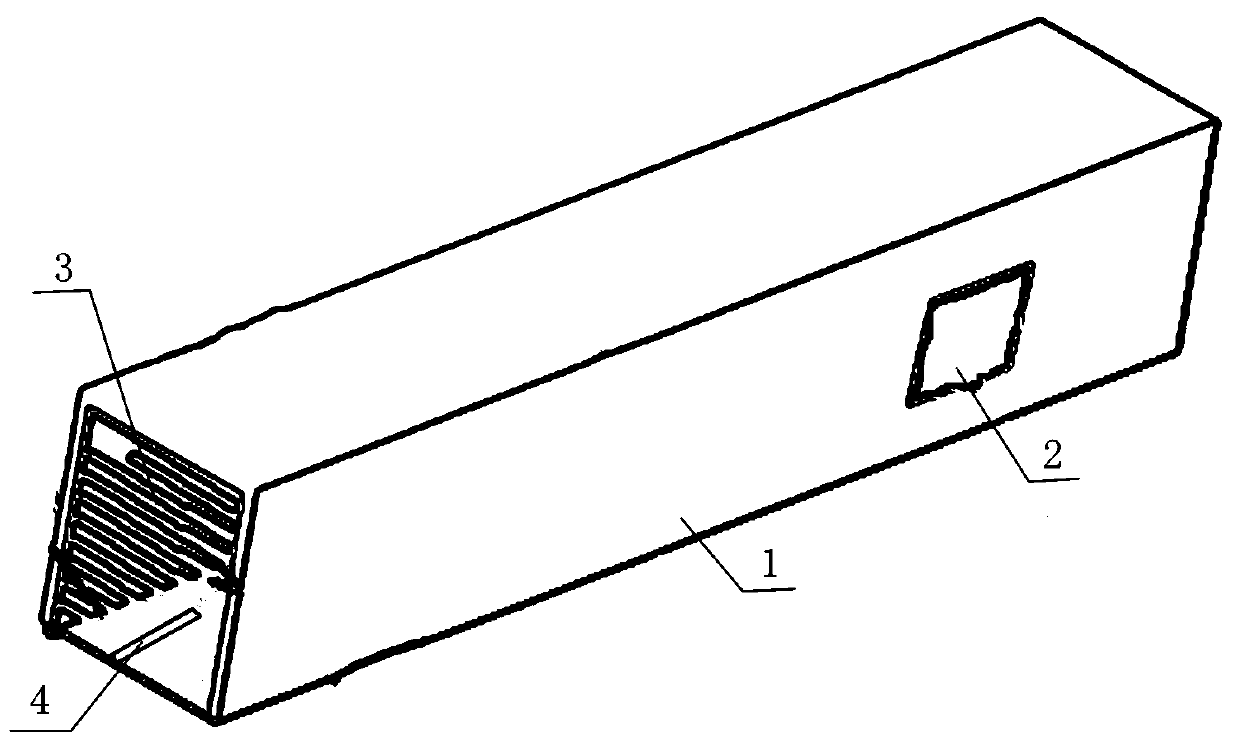

[0076] Figure 4 It is a schematic diagram of the cable channel main body of a full-scale underground space cable combustion fire simulation system provided by the embodiment of the present application. For the convenience of description, only the parts related to the embodiment of the present application are shown.

[0077] The cable channel body includes:

[0078] L-shaped steel structure in the channel, heat insulation layer, two-way cable support, explosion-proof glass isolation observation window, drainage groove;

[0079] The L-shaped steel structure, heat insulation layer, two-way cable support, explosion-proof glass isolation observation window, and drainage groove are rationally combined in sequence;

[0080] The L-shaped steel structure is composed of a transverse channel structure and a longitudinal channel structure, and the transverse channel structure is designed with different interfaces according to actual working conditions, and the longitudinal channel is de...

Embodiment 3

[0085] Figure 5 It is a full-scale underground space cable combustion fire simulation system and smoke pipe test system provided by the embodiment of the application. For the convenience of description, only the parts related to the embodiment of the application are shown.

[0086] The smoke pipe test system includes:

[0087] Laser smoke density test system, temperature field test system and calorimetry system.

[0088] The laser smoke density testing system is composed of a laser light source and a photoelectric sensor. The light source is emitted by the laser light source, and the photoelectric sensor receives the light signal, so as to realize the non-contact smoke density measurement.

[0089] The temperature field test system is composed of Omgea K-type thermocouples and couple brackets to achieve high-precision temperature field measurement. Among them, the selected OMEGA thermocouple is produced by the American omega engineering company. This company is the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com