Hollow anchor rod having functions of geological detection and anchoring and exhaust and grouting method of hollow anchor rod

A technology for geological exploration and bolting, which is applied in the installation of bolting, excavation, and earth-moving drilling and mining, etc., can solve the problems of inability to realize grouting, high construction safety risks, and multi-manpower, so as to facilitate the installation of prediction chips and reduce construction safety. Risk, anchoring powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

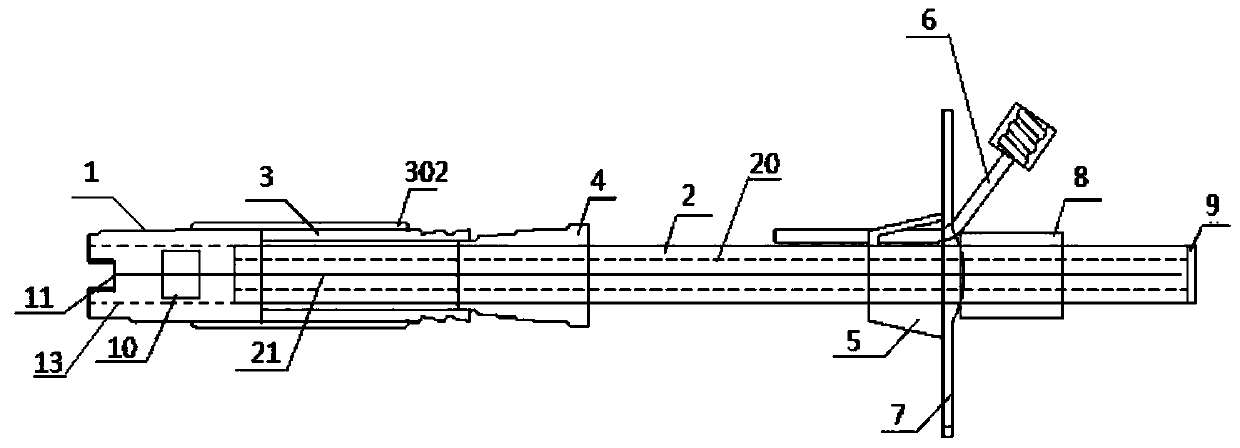

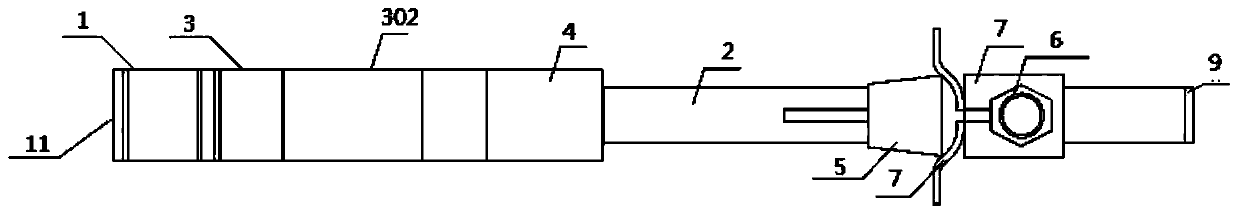

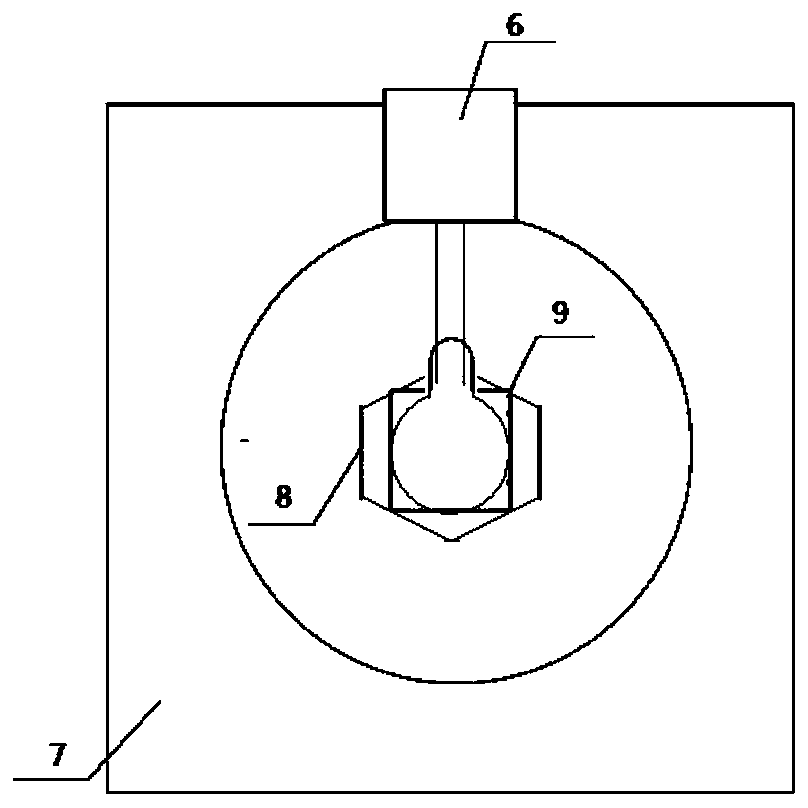

[0045] like Figure 1-6 As shown, a hollow bolt with geological detection and anchoring functions, including shell expansion anchor head 1, anchor rod 2, shell expansion piece 3, steel plug 4, grout stopper 5, grouting pipe 6, backing plate 7, Nut 8, plug 9, described expansion shell anchor head 1 is installed on the top of described hollow anchor rod, is connected and fixed with described anchor rod 2 by expanding shell piece 3 and steel plug 4, and its exterior is provided with prediction sensing chip 10 And the exhaust and slurry discharge groove 11, the anchor rod 2 is provided with a through anchor rod inner hole 20, and the inside of the anchor rod inner hole 20 is provided with a predictive sensor module and a signal transmission line 21; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com