High-temperature biogas production device in agricultural waste straw mixed raw materials

A technology of agricultural waste and mixed raw materials, which is applied in the field of high-temperature biogas production equipment, can solve the problems of difficult feeding and discharging, difficult sealing, and high operating costs, and achieve the effects of reasonable design, solving the problem of slag discharge, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

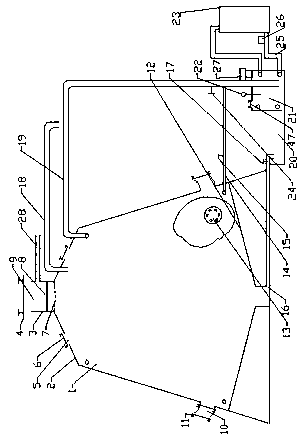

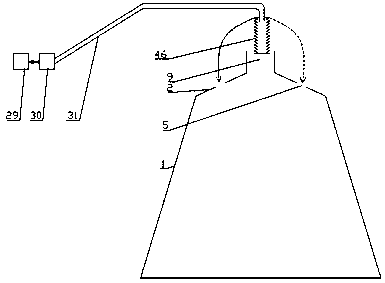

[0044] like Figure 1-5 As shown in , the high-temperature biogas production device of agricultural waste and straw mixed raw materials includes a double-cone fermenter and an automatic slagging system. Tank top 2, gas storage tank 3, gas storage tank cover 4 and bolt seal ring, peripheral feed port 5, feed port cover 6 and bolt seal ring, anti-floating filter grate 7, biogas slurry upper plane 8, center feed Port 9, corresponding to manual assisted slag discharge window 10, window cover 11 and bolt sealing ring, inverted cone fermenter bottom 12, air guide pipe 28, slag discharge channel 16, slag discharge valve 17, overflow pipe 18, biogas slurry return pipe 19. Biogas slurry tank 20, thermometer 22, boiler 23, boiler heating circulation pipe 25, circulation pump 26, biogas slurry return motor 27, the top of the ladder-type fermentation tank 1 is integrally equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com