Ethylene propylene diene monomer rubber sealing material with low compression permanent deformation, and preparation method thereof

A technology of permanent deformation of EPDM rubber, which is applied in the field of EPDM rubber, and can solve the problem of large influence range of mechanical properties of EPDM rubber, increase of elastic modulus, and decrease of deformation performance of EPDM rubber, etc. problems, achieve good flexibility and deformability, reduce compression set, and good elastic sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

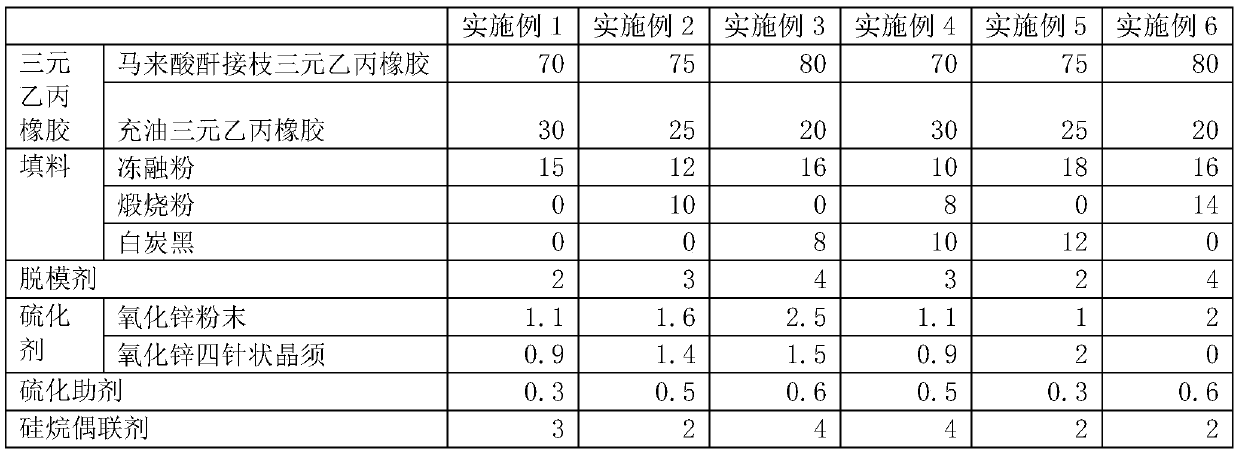

Embodiment 1~6

[0052] A kind of EPDM rubber sealing material with low compression set, its raw material includes the following composition and its mass parts,

[0053] EPDM rubber 100 parts,

[0054] Filling 15-30 parts,

[0055] Release agent 2 to 4 parts,

[0056] 2 to 4 parts of vulcanizing agent,

[0057] Vulcanization aid 0.3~0.6 parts,

[0058] 18-25 parts of carbon black,

[0059] Sulfur S-80 0.1~0.4 parts,

[0060] 2-4 parts of silane coupling agent.

[0061] 70-80 parts of EPDM rubber is maleic anhydride grafted EPDM rubber, and the rest is oil-extended EPDM rubber.

[0062] The filler includes one or more of freeze-thaw powder, calcined powder, and white carbon black, and the freeze-thaw powder accounts for more than 33wt% of the filler, the calcined powder accounts for less than 45.5wt% of the filler, and the white carbon black is The proportion of the filler is less than 40wt%.

[0063] The particle size of the freeze-thaw powder is 400-600nm. The preparation method of th...

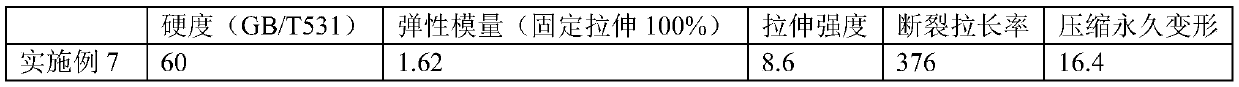

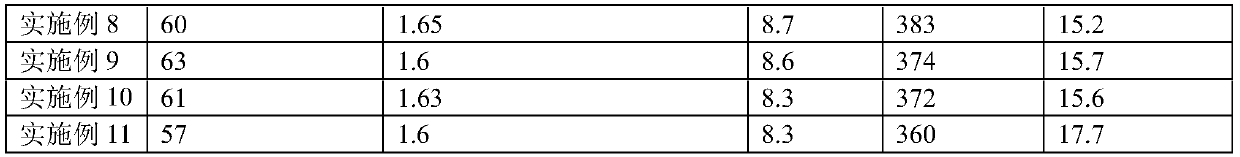

Embodiment 7

[0101] An EPDM sealing material with low compression set, based on Example 4, the difference is that the catalyst used is zinc sulfide powder.

Embodiment 8

[0103] An EPDM sealing material with low compression set, based on Example 4, the difference is that the catalyst used is zinc sulfide whisker.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com