Flexible gradient fatigue-resistant rubber and preparation method thereof

A fatigue-resistant, rubber-based technology, applied in the field of rubber, can solve problems such as the difficulty of simultaneous vulcanization molding, the decline in the mechanical properties of rubber materials, fatigue resistance, and the difficulty of molding, so as to ensure orderly gradient distribution, reduce quality, and achieve The effect of the Soft Gradient property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

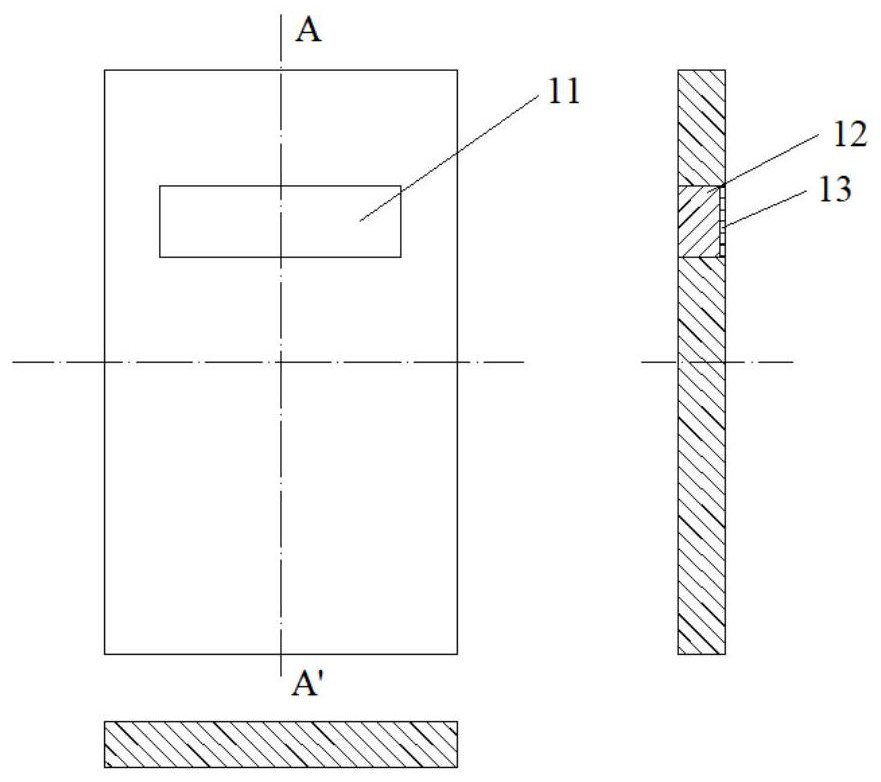

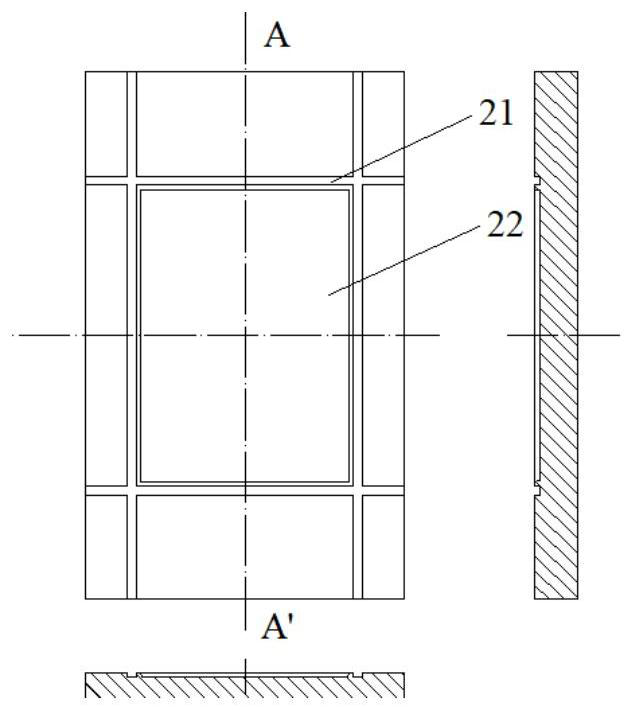

[0028] The preparation method of the flexible gradual fatigue-resistant lightweight rubber according to an exemplary embodiment of the present invention includes the following steps:

[0029] Step 1: Mix 5-15 parts with an average particle size of 7-40nm and a specific surface area of 100-500m 2 Add nano-silica per gram and 30-50 parts of hollow melamine microspheres with a particle size of 2-10 μm to 5-10 parts of liquid coumarone, stir at 100-500 rpm for 5-20 minutes, and drop 0.05-0.15 parts of Si69 , continue to stir for 3-5min, add to 90 parts of liquid rubber with a molecular weight of 10000-30000, the rubber is any one of natural rubber, styrene-butadiene rubber or butadiene rubber, stir for 10-20min, continue to add zinc oxide, stearin Acid, anti-aging agent and accelerator, stirred for 15-30min to obtain mixture A, the zinc oxide is a zinc oxide predispersion with 50% content, the dispersion medium is aromatic oil, and the stearic acid is 50% content Stearic acid p...

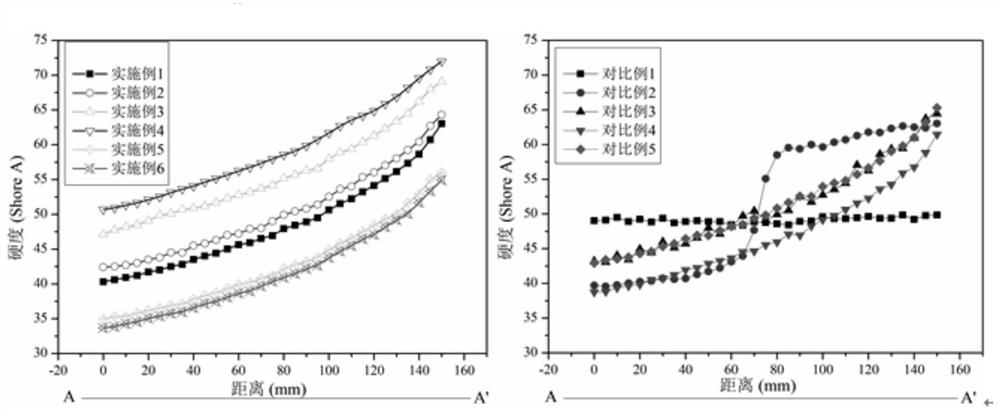

Embodiment 1

[0039] Step 1: Mix 5 parts with an average particle size of 7nm and a specific surface area of 500m 2 Nano-silica per gram and 30 parts of hollow melamine microspheres with a particle size of 2 μm were added to 5 parts of liquid coumarone, stirred at 100 rpm for 20 minutes, 0.05 parts of Si69 was added dropwise, continued to stir for 3 minutes, and 90 parts of melamine with a molecular weight of 10000 In the liquid rubber, rubber is natural rubber, stirs 10min, continues to add 10 parts of zinc oxides, 4 parts of stearic acid, 4 parts of antioxidants and 4 parts of accelerators, stirs 15mins, obtains mixture A, and described zinc oxide is 50 % content of the zinc oxide predispersion, the dispersion medium is an aromatic hydrocarbon oil, and the stearic acid is the stearic acid predispersion of 50% content, the dispersion medium is an aromatic hydrocarbon oil, and the accelerator is 50% of the content of the accelerator M. Accelerator pre-dispersion, dispersion medium is arom...

Embodiment 2

[0043] Step 1: Take 7 parts with an average particle size of 15nm and a specific surface area of 200m 2 Nano-silica per gram and 35 parts of hollow melamine microspheres with a particle size of 4 μm were added to 6 parts of liquid coumarone, stirred at 150 rpm for 8 minutes, 0.08 parts of Si69 was added dropwise, continued to stir for 4 minutes, and added to 90 parts of In the liquid rubber, rubber is natural rubber, stirs 12min, continues to add 10 parts of zinc oxides, 4 parts of stearic acid, 6 parts of antioxidants and 6 parts of accelerators, stirs 18mins, obtains mixture A, and described zinc oxide is 50 % content of the zinc oxide predispersion, the dispersion medium is an aromatic oil, and the stearic acid is the stearic acid predispersion of 50% content, the dispersion medium is an aromatic oil, and the accelerator is the 50% content of the accelerator NOBS Accelerator pre-dispersion, the dispersion medium is aromatic oil, the anti-aging agent is 50% content anti-ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com