A processing method for a butterfly-shaped composite material sandwich part

A composite material and processing method technology, applied in the field of composite material parts manufacturing, can solve the problems of long manufacturing cycle, high cost, and easily damaged surface of forming molds, and achieve the effects of uniform pressure transmission, accurate relative position, and completely consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

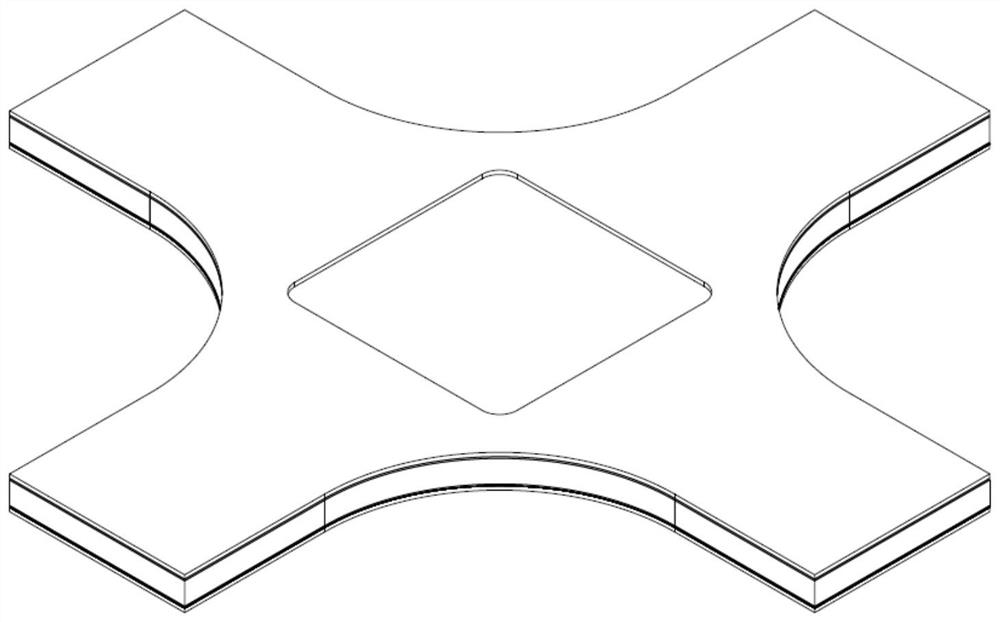

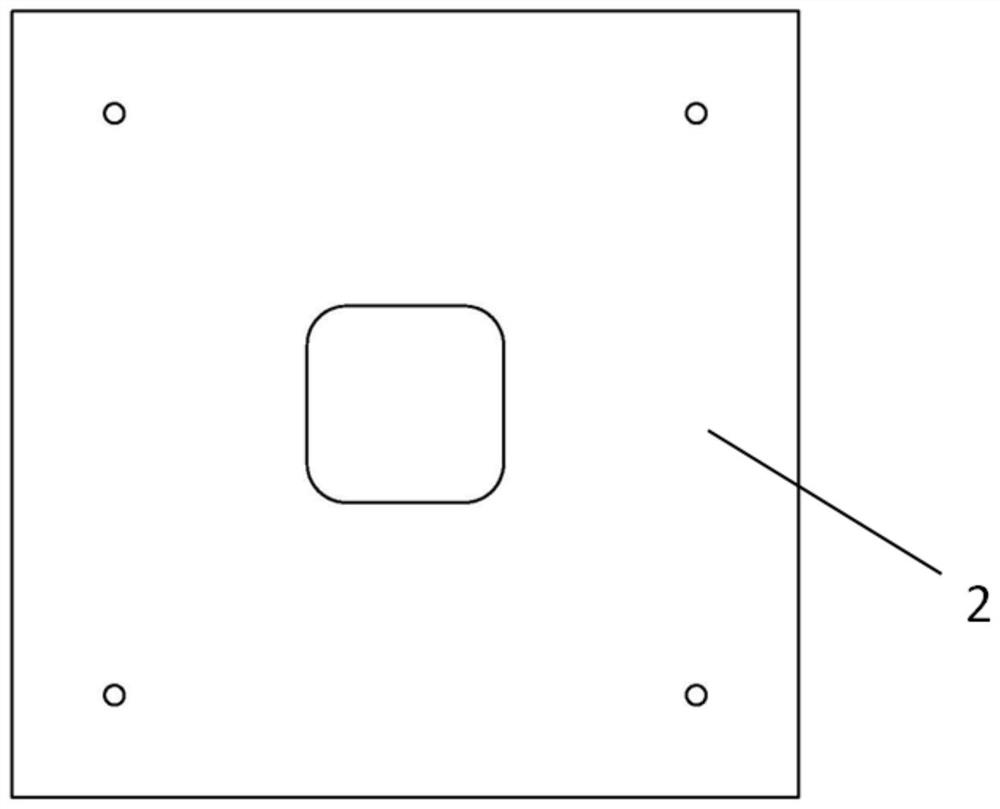

[0023] In this example, the butterfly-shaped composite material sandwich part is composed of the middle core layer 3, the upper panel 7 and the lower panel 8 sandwiching the upper and lower surfaces of the core layer, and the upper backing plate 1 and the lower backing plate 2 on the outer layers of the upper and lower panels. Openings with exactly the same shape and position should be processed on the backing plate, and the openings completely expose the surface of the panel below. Processing methods such as figure 1 -5 shown.

[0024] Cut the composite upper backing plate 1 and lower backing plate 2 with the same shape on the cured composite backing board wool, and process two craft pads in the wool surplus area that are completely consistent with the shape and thickness of the center opening of the backing board piece 5;

[0025] The core layer 3 and the upper and lower panels are processed into a rectangle consistent with the shape of the backing plate, and at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com