Preparation process of explosion proof type magnetostrictive liquid level meter

A magnetostrictive liquid level and preparation process technology, which is applied in the direction of buoy liquid level indicators, etc., can solve the problems of a sharp increase in the cost of magnetostrictive liquid level gauges, very high straightness requirements for waveguide wires, and expensive imported waveguide wires. , to achieve good insulation, high hardness, and reduce storage space and length requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and embodiments:

[0029] The invention provides a preparation process of an explosion-proof magnetostrictive level gauge, which includes the following steps:

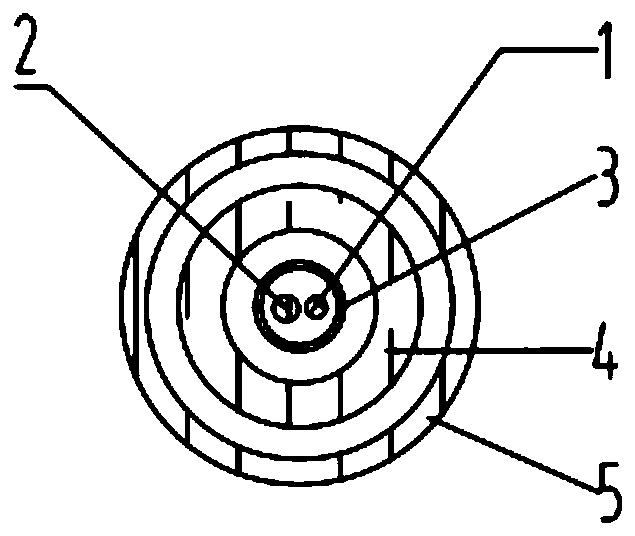

[0030] Step 1): Weld the waveguide wire 1 and the feeder line 2, weld one end of the waveguide wire 1 and the feeder line 2, and pass them into the inner protection tube 3 in parallel, and the solder joints of the waveguide wire 1 and the feeder line 2 are protected by a heat shrink tube;

[0031] Step 2): Insert the inner protective tube 3 into the corrugated tube 4, and then thread the corrugated tube 4 into the outer protective tube 5;

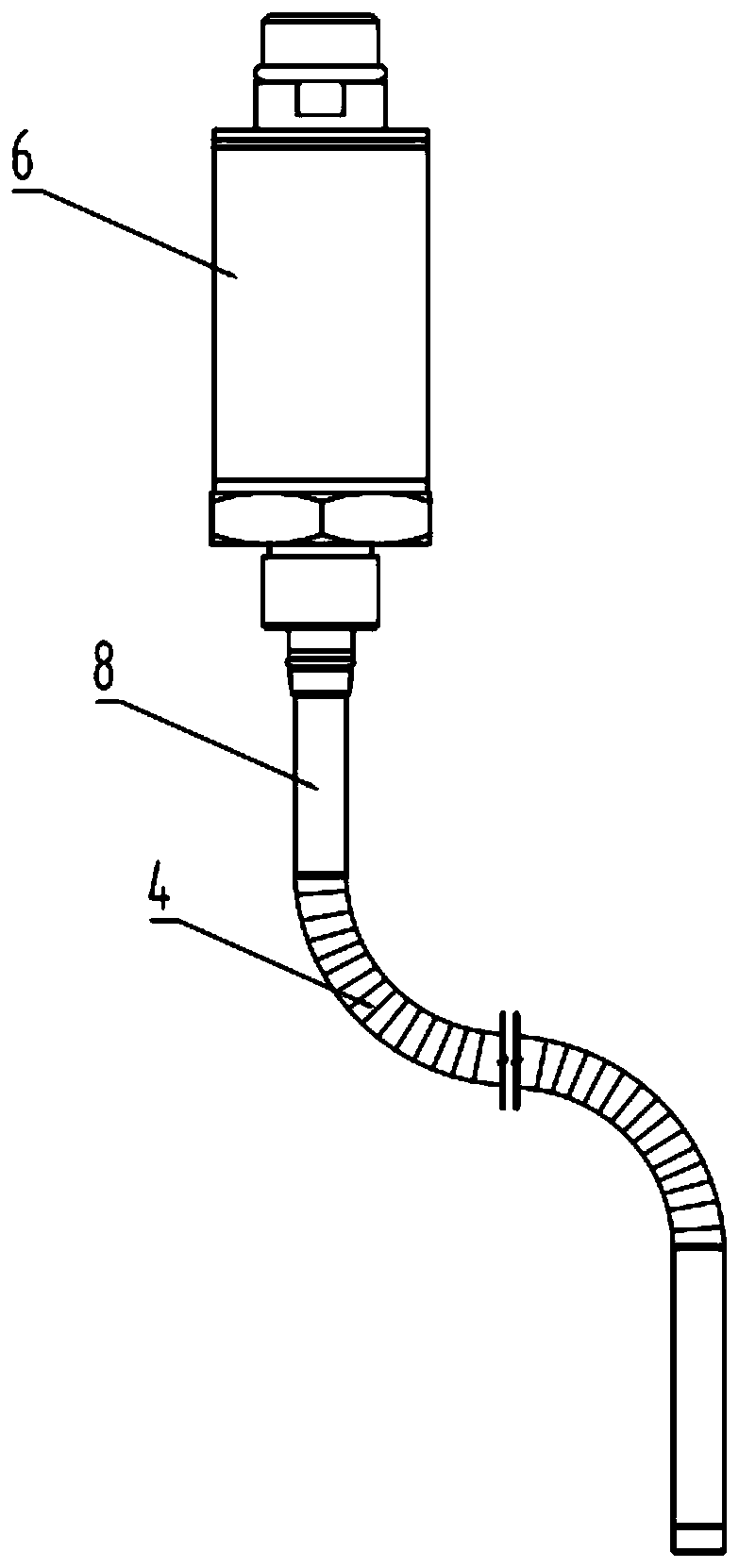

[0032] Step 3): The bellows 4 and the steel pipe 8 are welded, and the inner protection tube 3 and the electronic warehouse 6 are fixedly connected;

[0033] Step 4): Weld the steel pipe 8 and the electronic warehouse 6;

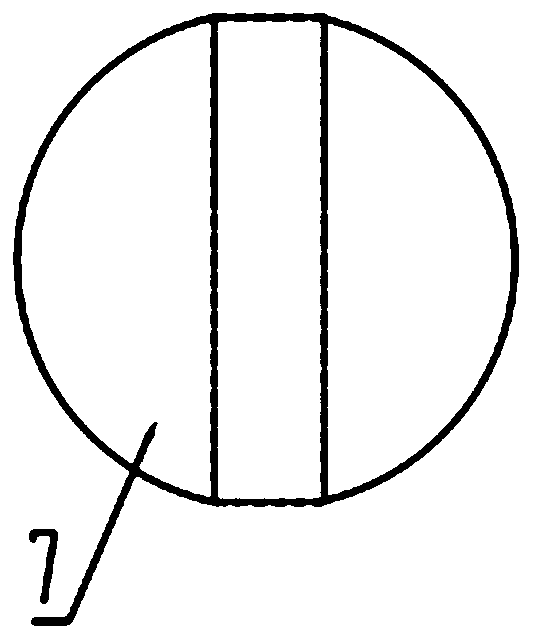

[0034] Step 5) Install the maglev ball 7 on the outside of the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetostriction coefficient | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com