Ferrule member

A ferrule and component technology, applied in the direction of optical components, light guides, optics, etc., can solve the problems of large transmission loss, difficulty in obtaining, dust sensitivity, etc., and achieve the effect of reducing transmission loss and increasing the optical damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

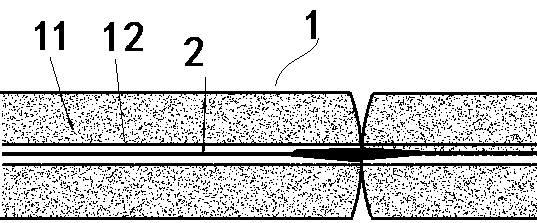

[0018] The specific embodiment of ferrule part of the present invention, as figure 1 As shown, the ferrule component 1 includes a ferrule housing 11, and the ferrule housing 11 is provided with an optical fiber passage 12 for inserting and fixing the optical fiber 2. The ferrule component 1 in this embodiment is a multi-core ferrule. The multi-core ferrule can connect multiple optical fibers 2 in one ferrule part, which can reduce the cost. In other embodiments, the multi-core ferrule can also be selected. In other embodiments, the ferrule component may also be a single-core ferrule. In this embodiment, the multi-core ferrule is specifically selected as an MT ferrule, and the optical fiber 2 inserted in the ferrule part 1 is an optical fiber with an enlarged mode field diameter at the butt end, that is, a single fiber with a mode field diameter greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com