A lens that directly produces a ring-shaped hollow focused beam

A focused beam and annular technology, applied in the field of optical lenses, can solve the problems of unfavorable practical application of annular hollow focused beams, difficulty in system installation and debugging, and difficulty in ensuring accuracy, so as to simplify the difficulty of system installation and debugging, low component cost, Easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

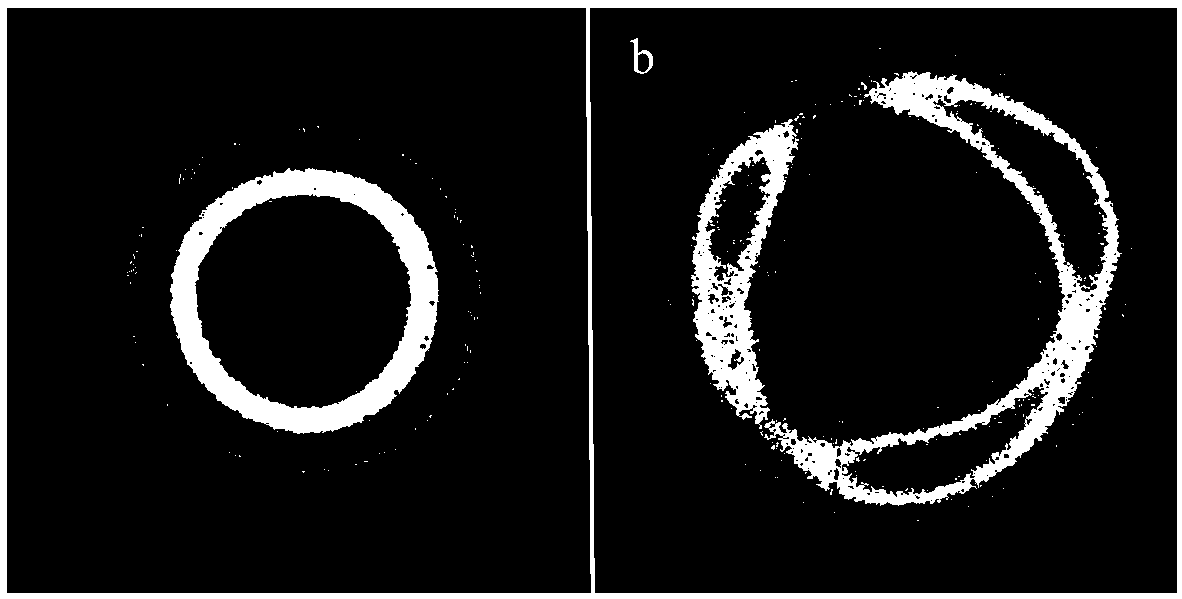

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

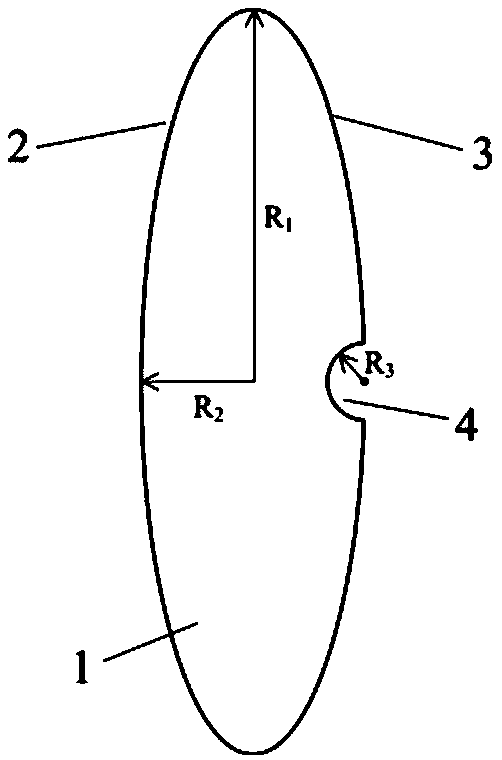

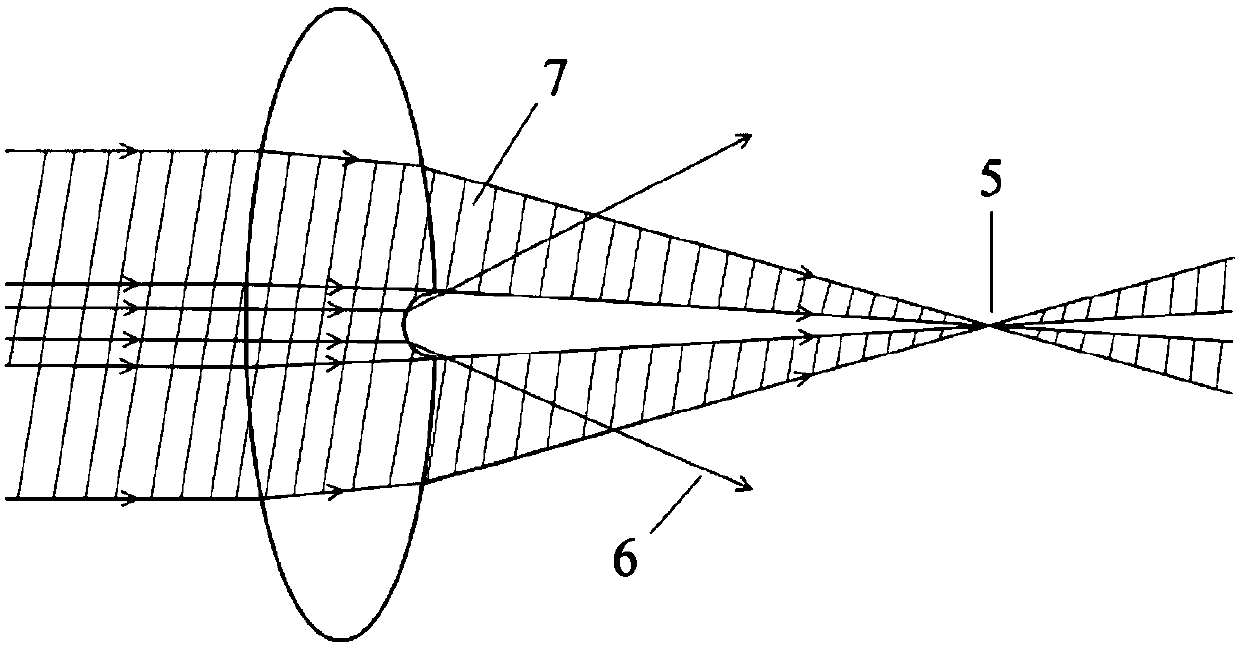

[0033] like figure 1As shown, the embodiment of the present invention is provided with convex lens 1, and convex lens 1 is provided with beam input surface 2 and beam output surface 3, is provided with concave cavity 4 at the center of the beam output surface 3 of convex lens 1, and the depth of concave cavity 4 is much smaller than The thickness of the central axis of the convex lens 1, the aperture of the concave cavity 4 is much smaller than the diameter of the convex lens 1, and the curvature of the surface of the concave cavity 4 is much larger than the curvature of the beam input surface 2 of the convex lens.

[0034] The section surface of the convex le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com