Adjustable hot-blast stove

A hot blast stove and furnace body technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of difficult adjustment accuracy, waste of resources, heavy workload, etc., to ensure fast supply, save costs, The effect of increasing the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

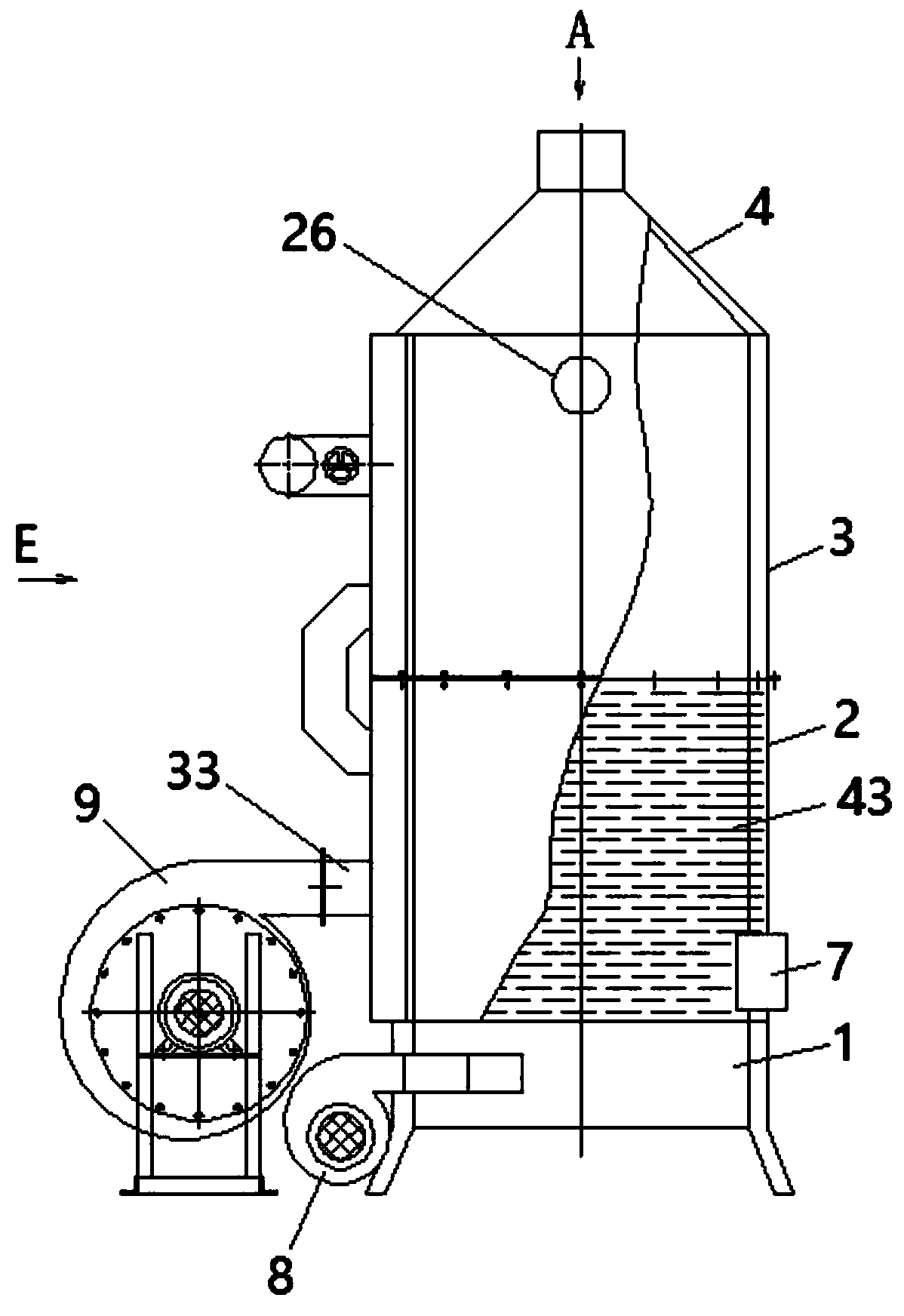

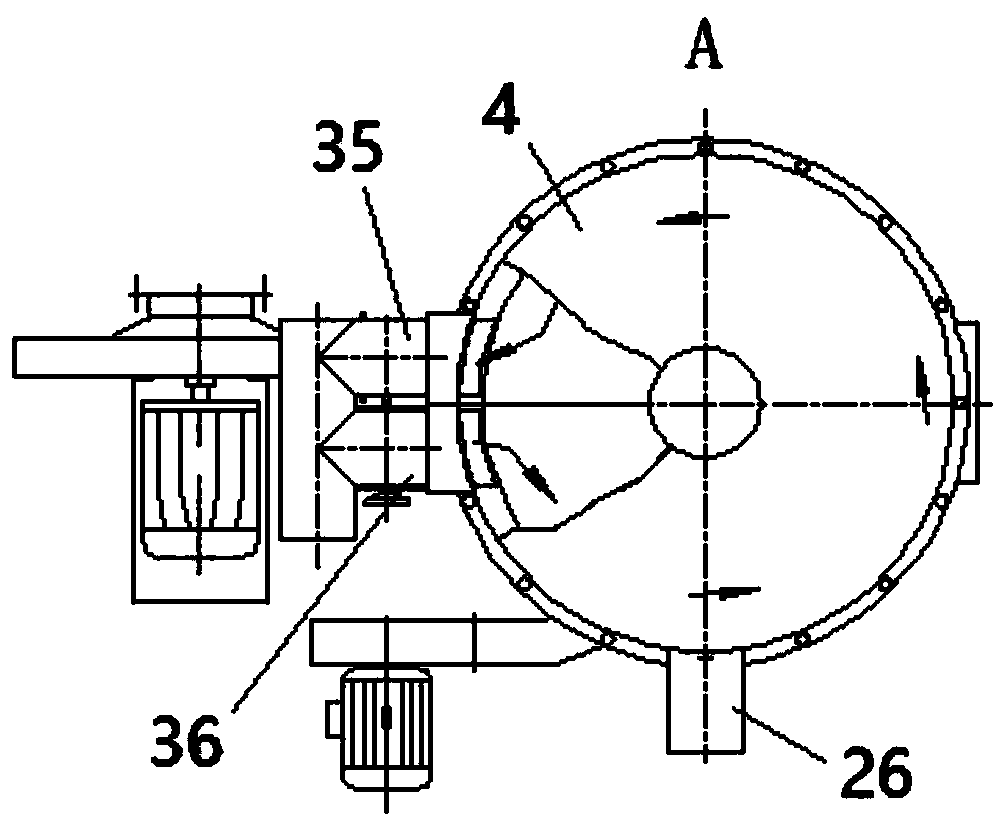

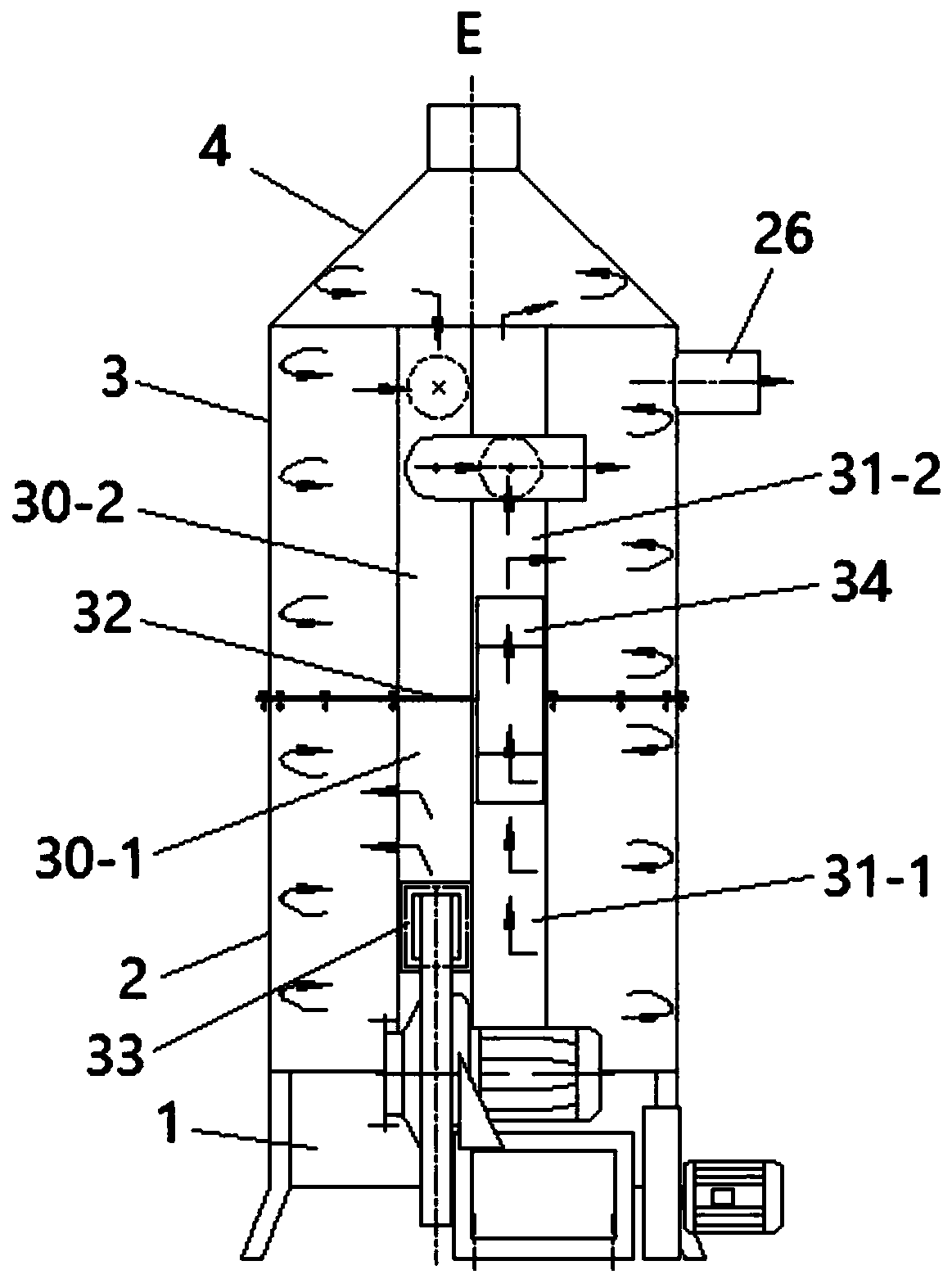

[0041] Referring to the accompanying drawings, an adjustable hot blast stove includes a furnace body. The furnace body includes a furnace bottom 1, a furnace body lower section 2, a furnace body upper section 3 and a furnace roof 4 distributed sequentially from bottom to top. The interior of the furnace bottom 1 A refractory brick 5 and a fire grate 6 are provided at the inner junction with the lower section 2 of the furnace body. One side of the bottom of the furnace bottom 1 and one side of the bottom of the lower section 2 of the furnace body are respectively provided with a slag discharge port and a fuel injection port 7. The furnace body Combustion-supporting blower 8 and high-pressure blower 9 are respectively provided on one side of the furnace, and a plurality of combustion-supporting air ducts 10 are respectively provided in the furnace bottom 1. One end of the plurality of combustion-supporting air ducts 10 is closed, and the other end is connected with the air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com