A method of controlling the martensitic structure of r260 rail flash welded joints

A technology of head martensite and rail, which is applied in the field of controlling the martensite structure of R260 rail flash welding head, can solve the problems of failing to pass the welding type inspection, appearing point-like martensite structure, and shifting to the right, and achieves good promotion and application prospects. Simple effect of control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

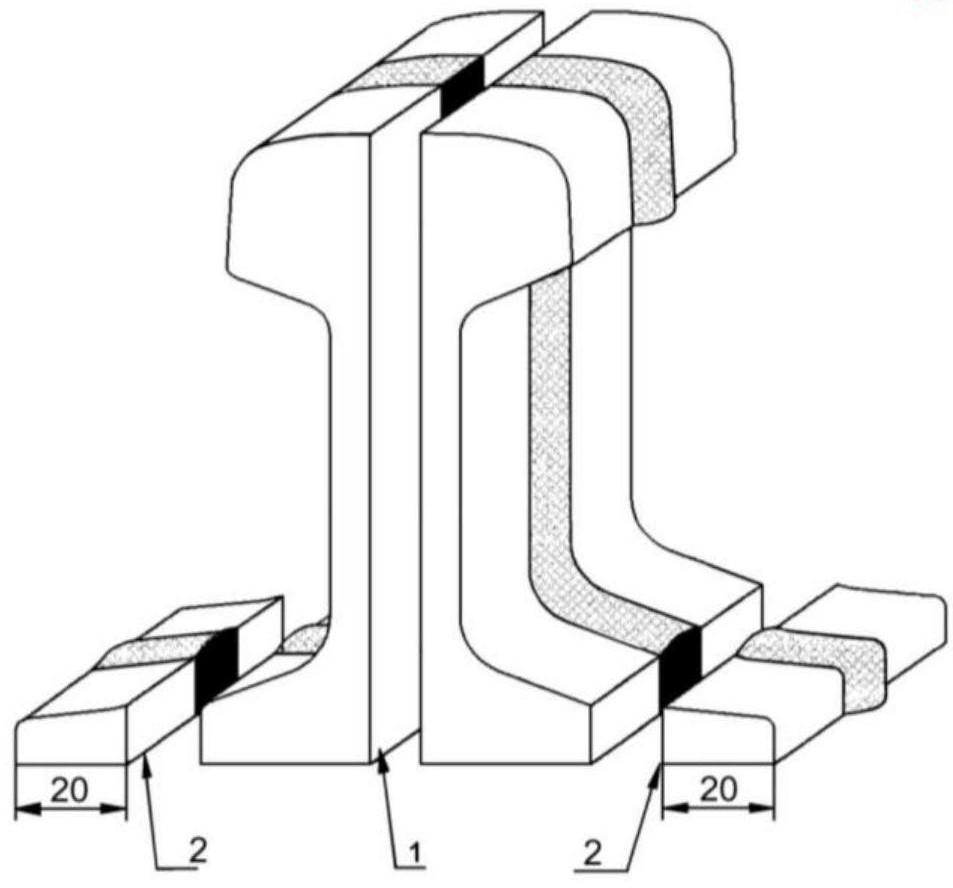

[0025] When controlling the content of Mn in the parent metal composition of R260 rail at the lower limit of 0.75%, the content of C in other chemical components at the upper limit, and Si at ≤0.30%, it is necessary to add 0.25% Cr and 0.03% V to the molten steel during the steelmaking process. In order to meet the mechanical properties of the hot-rolled rails that are normally produced and rolled by the Universal Line, Rm≥880MPa, tread hardness≥260HB, use rail mobile flash welders or fixed flash welders, and use pulsation or preheating flash with a large heat input of 7.5MJ After welding, the actual welding upsetting amount is kept at 13.0mm, and the joint is air-cooled to room temperature after the joint pushing is completed.

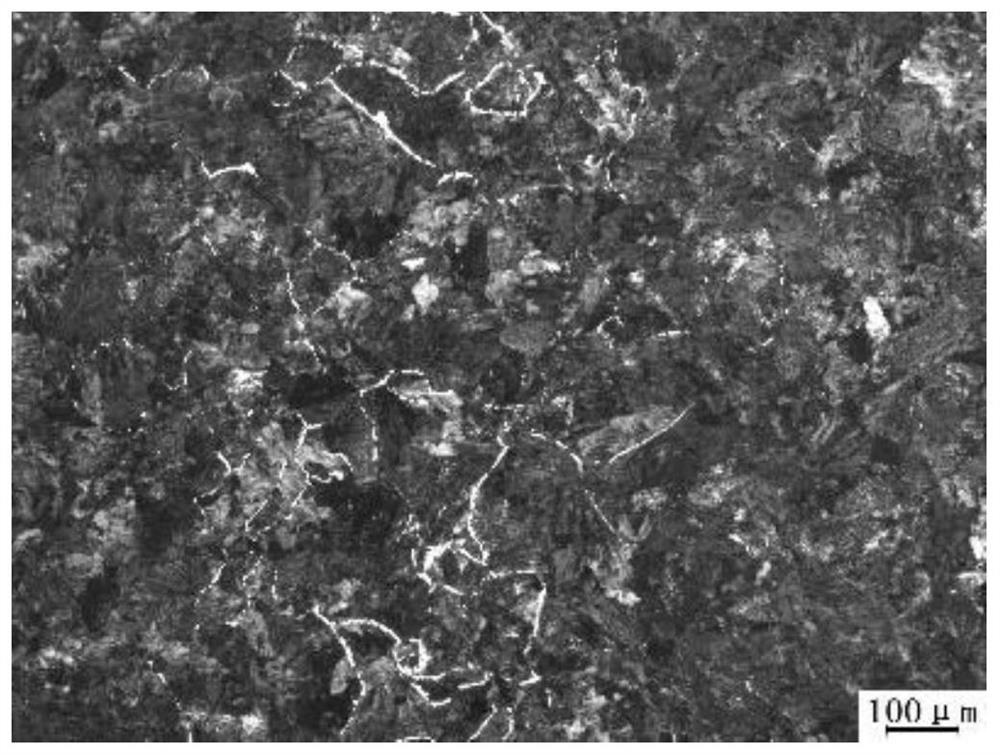

[0026] After testing, according to EN14587-2:2009 standard requirements of rail head and rail foot specified position inspection confirmed no martensitic structure, the corresponding metallographic structure is as follows figure 2 As shown, and in th...

Embodiment 2

[0028] When controlling the content of Mn in the parent metal composition of R260 rail to be at the lower limit of 0.77%, the content of other chemical components C at the upper limit, and Si at ≤0.30%, it is necessary to add 0.25% Cr and 0.03% V to the molten steel during the steelmaking process. In order to meet the mechanical properties of the hot-rolled rails that are normally produced and rolled by the universal line, the mechanical properties of the hot-rolled rails should meet Rm≥880MPa, and the hardness of the tread surface should be ≥260HB. The rail mobile flash welder or fixed flash welder is used, and a large heat input of 8.0MJ is used. Pulse or preheating flash After welding, the actual welding upsetting amount is kept at 13.5mm, and the joint is air-cooled to room temperature after the joint pushing is completed.

[0029] After testing, according to the requirements of EN14587-2:2009 standard, it is confirmed that there is no martensitic structure in the specified...

Embodiment 3

[0031] When controlling the content of Mn in the parent material of R260 rail to be at the lower limit of 0.80%, the content of C in other chemical components at the upper limit, and Si at ≤0.30%, it is necessary to add 0.22% Cr and 0.03% V to the molten steel during the steelmaking process. In order to meet the mechanical properties of the hot-rolled rails that are normally produced and rolled by the universal line, Rm≥880MPa, tread hardness≥260HB, use the rail mobile flash welder or fixed flash welder, and use 8.5MJ large heat input pulsation or preheating flash After welding, the actual welding upsetting amount is kept at 14.0mm, and the joint is air-cooled to room temperature after the joint pushing is completed.

[0032] After testing, according to the requirements of EN14587-2:2009 standard, the position inspection of the rail head and rail foot has confirmed that there is no martensite structure, and the static bending load of five consecutive R260 rail joints in this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com