Method for controlling martensite structure of R260 steel rail flash welding head

A head martensite and rail technology, which is used in the field of controlling the martensite structure of R260 rail flash welded joints, can solve the problems of point-like martensite structure, failure to pass the welding type inspection, right shift, etc., and achieve a simple and good control process. The effect of promoting application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

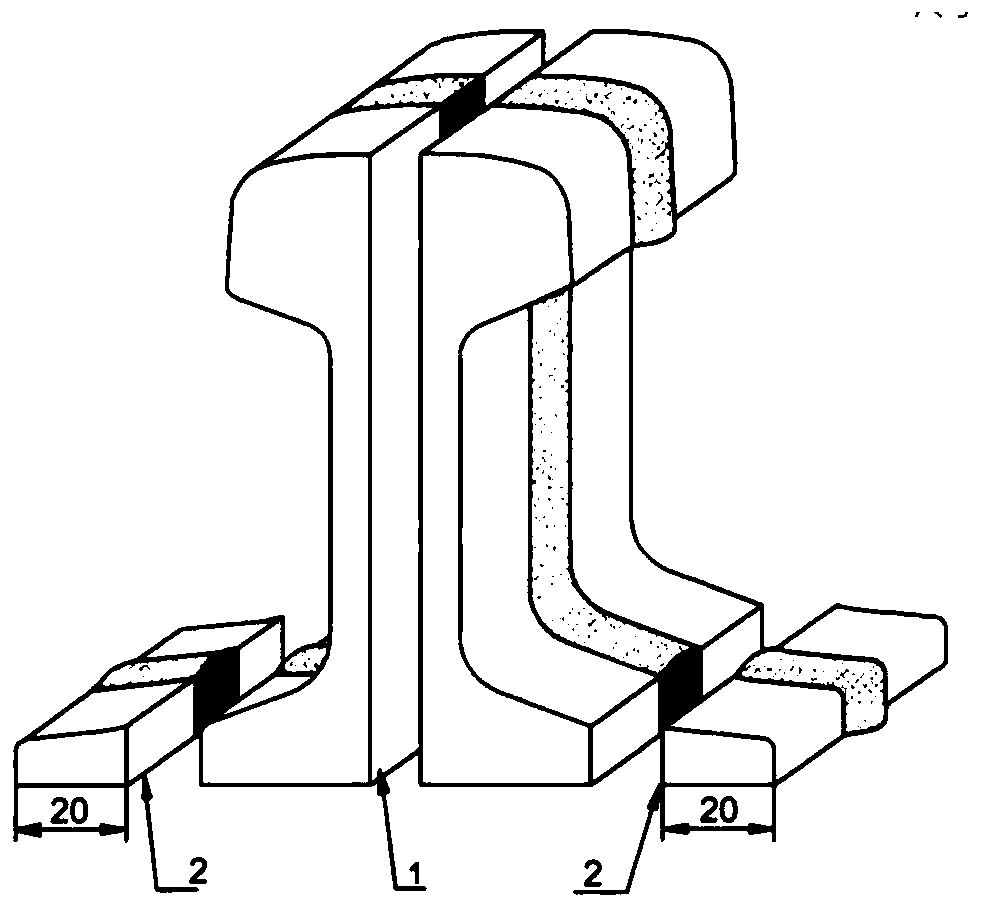

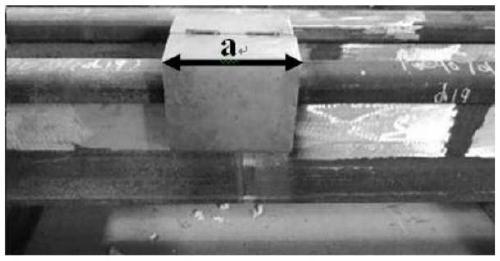

[0036]Control the Mn content in the base metal composition of R260 rails to 1.1% Mn, the C content of other chemical components to the middle and lower limits, and keep Si at ≤0.30%. The mechanical properties of the hot-rolled rails that are normally produced and rolled by the universal line meet Rm≥880MPa, and the tread hardness ≥260HB, use rail mobile flash welder or fixed flash welder, adopt 8.5MJ large heat input after pulsating or preheating flash welding, the actual welding upsetting amount is kept at 14.0mm, when the joint pushing is completed, it is air-cooled to 550 When the temperature is lower than ℃, the rail head insulation device with a thickness of 35mm embedded in aluminosilicate fiber cotton in the hinged structure or the full-section rail insulation device is used for slow cooling. The length of the insulation and slow cooling device is 210mm. With the device, allow the joint to air cool to room temperature.

[0037] After testing, the joints are inspected ac...

Embodiment 2

[0039] Control the Mn content in the base metal composition of R260 rail to 1.03% Mn, the C content in other chemical components to the middle and lower limits, and keep Si at ≤0.30%. The mechanical properties of the hot-rolled rails that are normally produced and rolled by the universal line meet Rm≥880MPa, and the tread hardness ≥260HB, use rail mobile flash welding machine or fixed flash welding machine, adopt 8.5MJ large heat input after pulsating or preheating flash welding, the actual welding upsetting amount is kept at 14.00mm, when the joint pushing is completed, it is air-cooled to 560 When the temperature is below 280°C, use the rail head heat preservation device with a hinged structure embedded in 35mm thick aluminosilicate fiber cotton or the full-section rail heat preservation device for slow cooling. With the device, allow the joint to air cool to room temperature.

[0040] After testing, the joints are inspected according to the specified position of the rail he...

Embodiment 3

[0042] Control the content of Mn in the parent material of R260 rail to 1.07%, the content of C in other chemical components to the middle and lower limits, and keep Si at ≤0.30%. The mechanical properties of the hot-rolled rails normally produced and rolled by the universal line meet Rm≥880MPa, and the tread hardness≥ 260HB; use rail mobile flash welding machine or fixed flash welding machine, adopt 9.0MJ large heat input after pulsating or preheating flash welding, the actual welding upsetting amount is kept at 14.5mm, and when the joint pushing is completed, it is air-cooled to 560°C When using a hinged structure with 35mm-thick aluminosilicate fiber cotton embedded in the rail head insulation device or a full-section rail insulation device for slow cooling, the length of the insulation and slow cooling device is 220mm. When the slow cooling temperature is below 280°C, remove the insulation device , and allow the connector to air cool to room temperature.

[0043] After tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tread hardness | aaaaa | aaaaa |

| Deflection | aaaaa | aaaaa |

| Deflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com