Dust disposing device

A dust treatment and body technology, which is applied in the methods of preventing pollution, sleeve/socket connection, pipe/pipe joint/pipe fittings, etc. Dust accumulation and other problems, to achieve the effect of increasing the failure rate, increasing the number of maintenance, and easy cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

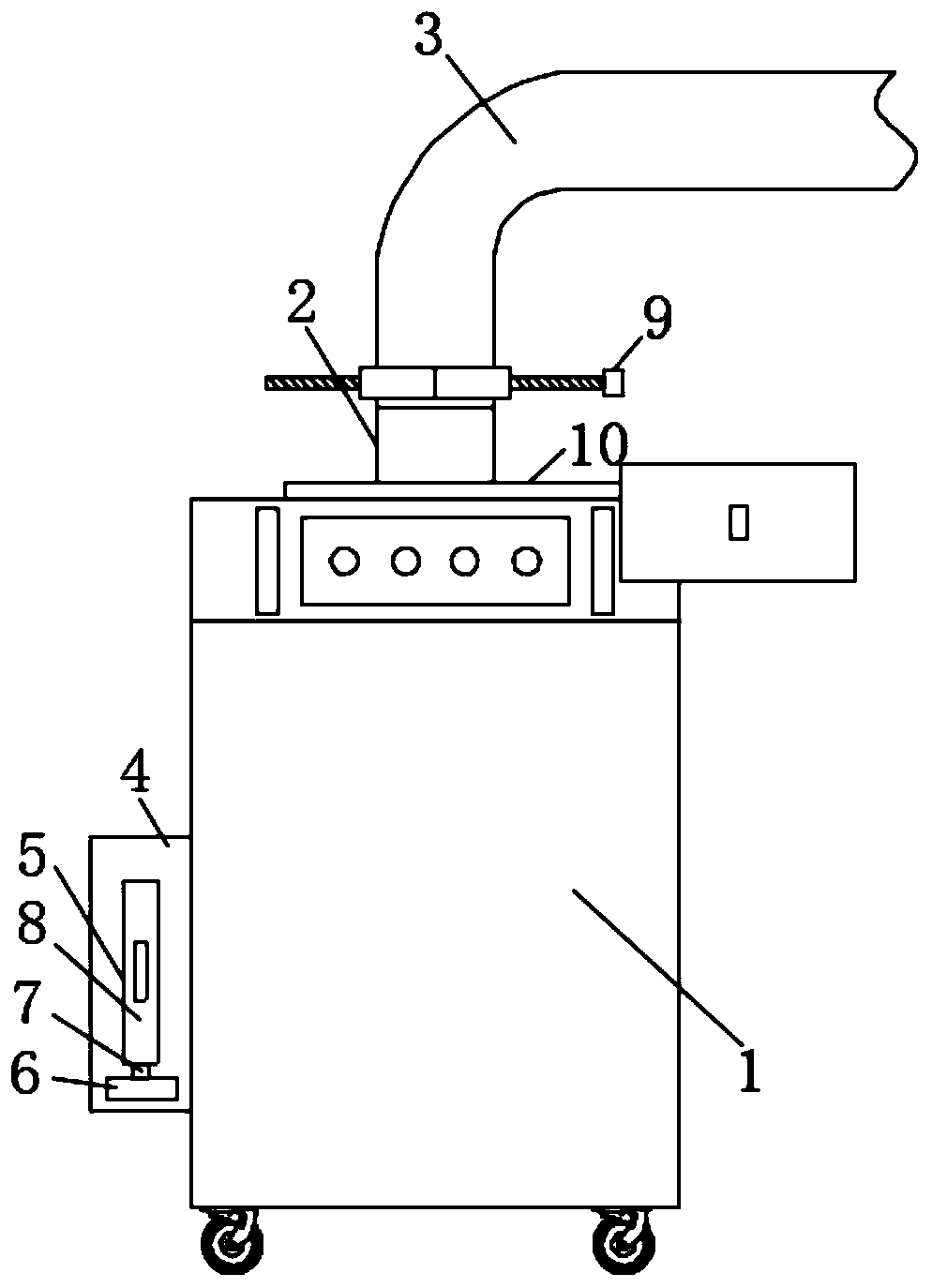

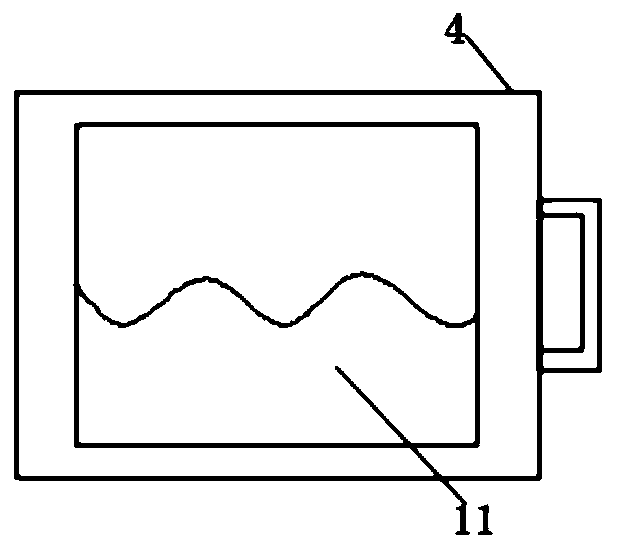

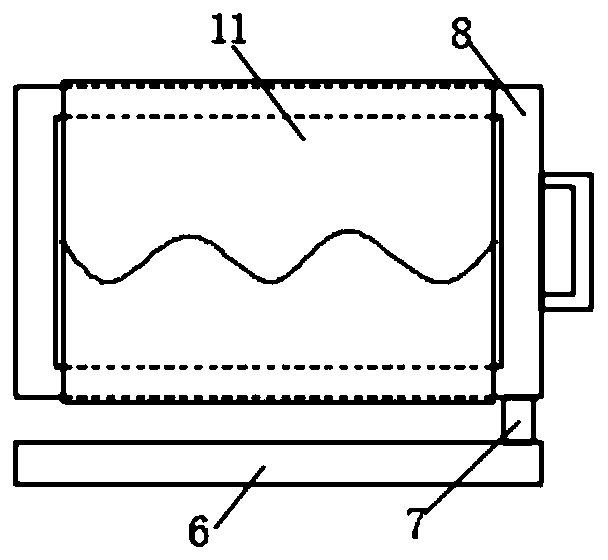

[0024] see Figure 1 to Figure 5 , the present invention provides a technical solution: a dust treatment device, including a body 1, a nozzle 2, and an air pipe 3, a fixed frame 4 is arranged on the side of the body 1, and a sliding mechanism 5 is arranged on the surface of the fixed frame 4, and the sliding mechanism 5 includes Slide plate 6, connecting column 7, square frame 8, the outside of square frame 8 is provided with gauze cover 11, and the top of body 1 is provided with firm mechanism 9, and firm mechanism 9 comprises fixed beam 12, screw mandrel 13, slide block 14, firm The half ring 15, the fixed beam 12 is in a vertical state, the screw mandrel 13 passes through the fixed beam 12 vertically, the body 1 is provided with a shielding mechanism 10 near the side position, and the shielding mechanism 10 includes a stable beam 16, a connecting rod 17, and a shielding cover 18, A connecting block 19 is arranged inside the stabilizing beam 16 .

[0025] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com