Graphene aerogel hollow fiber, its preparation method and application

A graphene aerogel, graphene hydrogel technology, applied in the manufacture of hollow filaments, chemical characteristics of fibers, chemical instruments and methods, etc. Multi-functional applications and other issues, to achieve excellent fluid transport performance, high-efficiency light-to-heat conversion performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned graphene airgel hollow fiber, which includes:

[0077] 1) Using coaxial needle-assisted sol-gel technology to prepare graphene hydrogel hollow fibers;

[0078] 2) Carry out supercritical fluid drying and / or freeze-drying treatment to described graphene hydrogel hollow fiber, while keeping gel network from being destroyed, remove solvent molecule in gel, obtain graphene airgel hollow fiber fiber.

[0079] In some preferred embodiments, the step 1) specifically includes:

[0080] A graphene oxide liquid crystal is provided, wherein the graphene oxide liquid crystal is concentrated from a graphene oxide aqueous solution, the graphene oxide aqueous solution is subjected to high-speed centrifugation, and the lower layer dispersion is collected to obtain the graphene oxide liquid crystal;

[0081] Inject the graphene oxide liquid crystal into the coagulation ba...

Embodiment 1

[0115] (a) 5mg / mL graphene oxide liquid crystal and 0.001wt% HCl solution were injected into 0.1wt% HCl solution at the same time through a coaxial needle at an injection speed of 10 μL / min to obtain a continuous graphene oxide hydrogel hollow fiber.

[0116] (b) soaking the graphene oxide hydrogel hollow fiber in step a) in an aqueous ascorbic acid solution, and standing at 5° C. for 72 hours to obtain a graphene hydrogel fiber.

[0117] (c) replacing the graphene hydrogel hollow fiber in step b) with an ethanol solvent, and supercritically drying at 33° C. for 24 hours to obtain a graphene airgel hollow fiber.

[0118] (d) uniaxially weaving the graphene airgel hollow fiber into a fabric in step c), and then crimping it to obtain a graphene airgel hollow fiber reel. Then the reel is soaked in the silica gel pre-solidified solution and cured to obtain the silica gel-graphene airgel hollow fiber reel composite. Test water evaporation performance under 1.0 sun.

[0119] The ...

Embodiment 2

[0122] (a) 15mg / mL graphene oxide liquid crystal and 6wt% calcium chloride solution are simultaneously injected into 3wt% cetyltrimethylammonium bromide aqueous solution at an injection speed of 50 μL / min through a coaxial needle to obtain continuous graphene oxide hydrogel hollow fibers.

[0123] (b) soaking the graphene oxide hydrogel hollow fiber in step a) in an aqueous solution of hydroiodic acid, and standing at 100°C for 0.5h to obtain a graphene hydrogel fiber.

[0124] (c) Freeze-drying the graphene hydrogel hollow fiber in step b) at -50° C. for 24 hours to obtain a graphene airgel hollow fiber.

[0125] (d) Integrating and winding the graphene airgel hollow fibers in step c) into bundles, then immersing the graphene airgel hollow fiber bundles in the ethylene oxide pre-solidified liquid, curing to obtain ethylene oxide - Graphene airgel hollow fiber bundle composite. Test water evaporation performance under 1.0 sun.

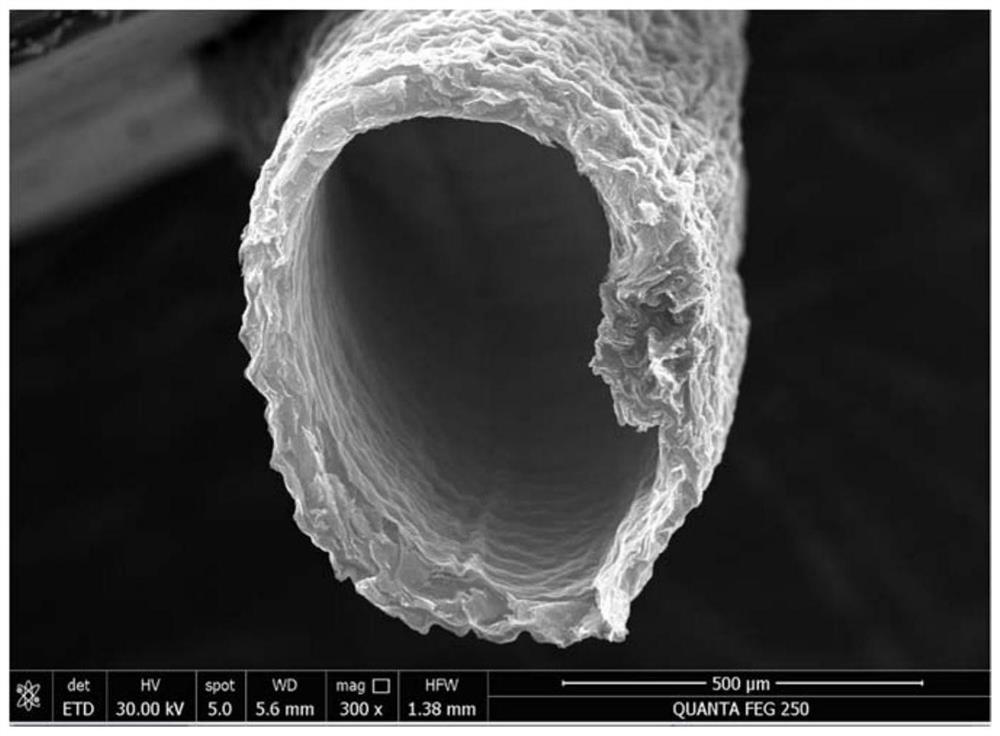

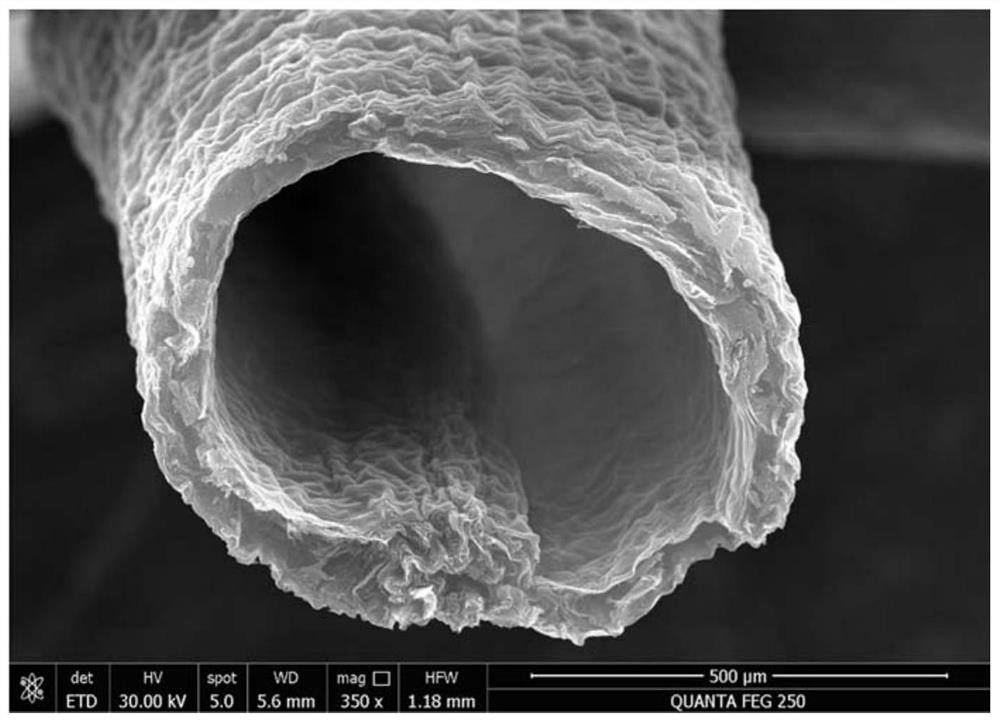

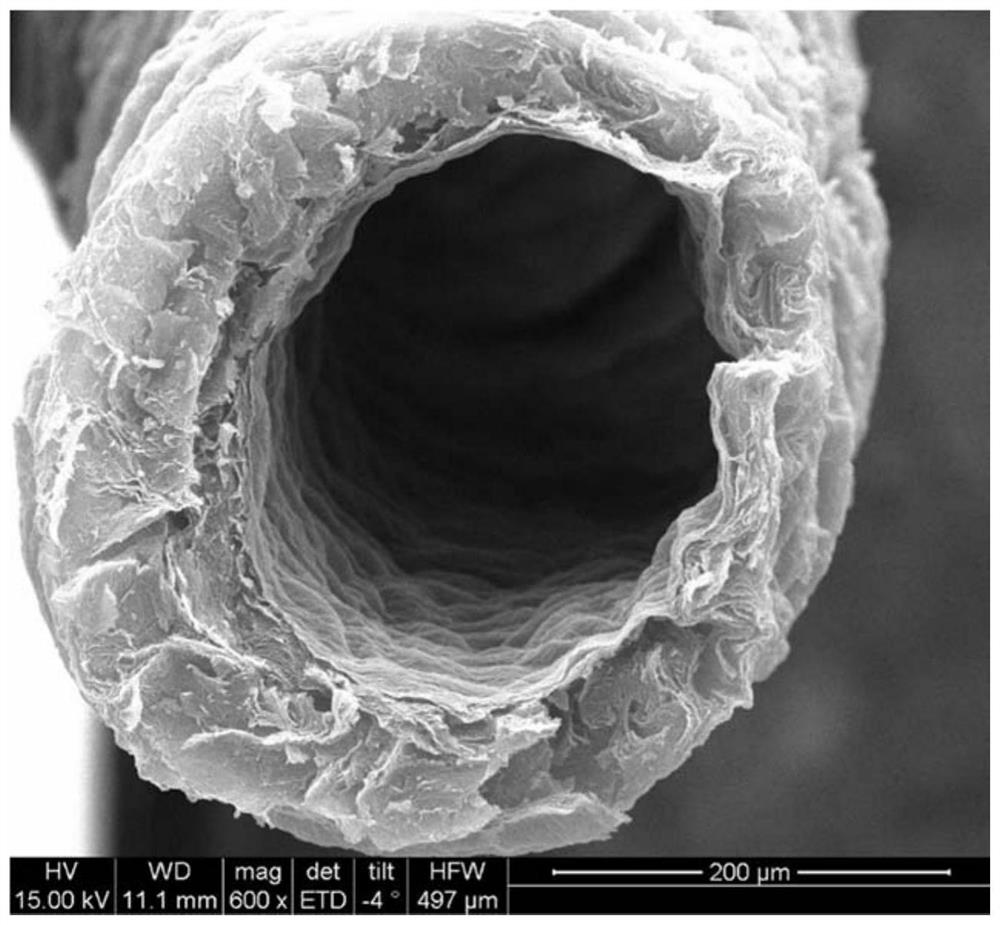

[0126] The scanning electron microscope photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com