Controllable release halloysite loaded molybdate corrosion inhibitor and preparation method thereof

A technology of molybdate and corrosion inhibitor, which is applied in the field of corrosion inhibitors, can solve problems such as economic loss, resource and energy waste, and reduce material performance, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Na 2 MoO 4 2H 2 O (8.0 g) was dissolved in 100 ml of deionized water, and then 4 g of HNTs was added thereto to form a suspension, called A suspension.

[0026] (2) Transfer suspension A to a 100ml beaker, then place the beaker in a vacuum tank, and use a vacuum pump to evacuate to 1.325E3Pa (1.325×10 3 Pa, that is, 1325Pa), and maintain the pressure for 90 minutes, and then put the system back under normal pressure for 30 minutes, which is called the completion of a loading process. Repeating the above cycle process will complete 3 loading experiments.

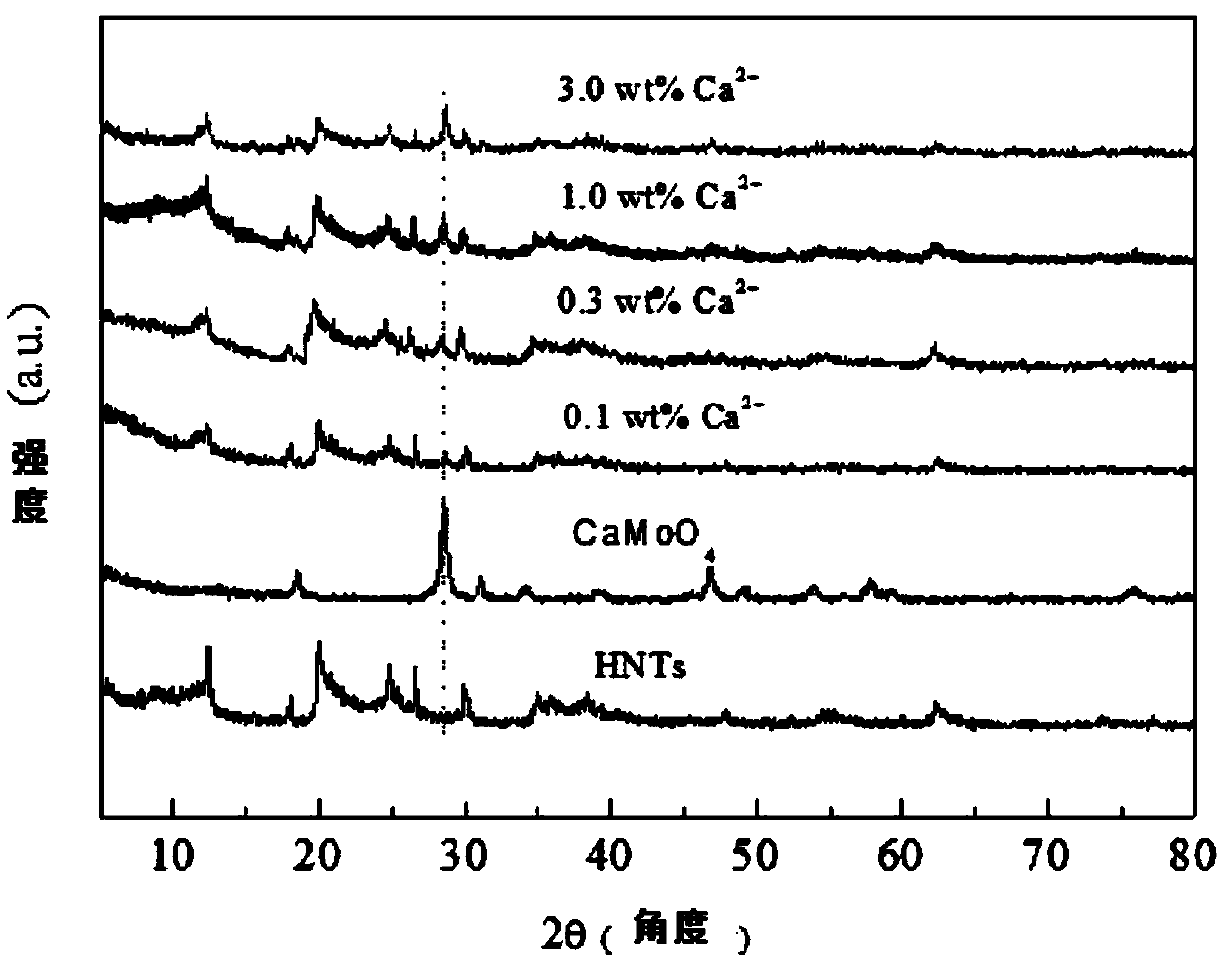

[0027] (3) After 3 times of loading, the sample was centrifuged, washed and re-dispersed to 5.0wt% CaCl 2 Stir in the solution for 10min, finally centrifuge, wash, dry at 80°C for 24h, and then grind to obtain HNTs loaded molybdate and CaMoO 4 Encapsulated corrosion inhibitor materials (Ca-Na 2 MoO 4 -HNTs).

Embodiment 2

[0029] (1) Na 2 MoO 4 2H 2 O (10.0 g) was dissolved in 100 ml of deionized water, and then 8 g of HNTs was added thereto to form a suspension, called A suspension.

[0030] (2) Transfer the suspension A to a 100ml beaker, then place the beaker in a vacuum tank, and use a vacuum pump to evacuate to 1.325E3Pa, and maintain the pressure for 60min, then put the system back under normal pressure 120min is called completing a loading process. Repeating the above cycle process will complete 6 loading experiments.

[0031] (3) After 6 times of loading, the sample was centrifuged, washed and re-dispersed to 3.0wt% CaCl 2 Stir in the solution for 15min, finally centrifuge, wash, dry at 40°C for 24h, and then grind to obtain HNTs loaded molybdate and CaMoO 4 Encapsulated corrosion inhibitor materials (Ca-Na 2 MoO 4 -HNTs).

Embodiment 3

[0033] (1) Na 2 MoO 4 2H 2 O (15.0 g) was dissolved in 100 ml of deionized water, and then 6 g of HNTs was added thereto to form a suspension, called A suspension.

[0034] (2) Transfer the suspension A to a 100ml beaker, then place the beaker in a vacuum tank, and use a vacuum pump to evacuate to 1.325E3Pa, and maintain this pressure for 120min, then put the system back under normal pressure 30min is called the completion of a loading process. Repeating the above cycle process will complete 2 loading experiments.

[0035] (3) The samples after three loadings were centrifuged, washed and re-dispersed to 1.0wt% CaCl 2 Stir in the solution for 5min, finally centrifuge, wash, dry at 60°C for 24h, and then grind to obtain HNTs loaded molybdate and CaMoO 4 Encapsulated corrosion inhibitor materials (Ca-Na 2 MoO 4 -HNTs).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com