N-15 marked microcystis and production method thereof

A technology of microcystin and N-15, which is applied in the preparation methods of peptides, microorganism-based methods, biochemical equipment and methods, etc., can solve the problem of unclear synthetic routes, single nitrogen source of medium, and uncontrollable processes, etc. problem, to achieve the effect of simple and easy to operate production method, low cultivation cost and easy quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0078] The purification of embodiment 3 microcystins

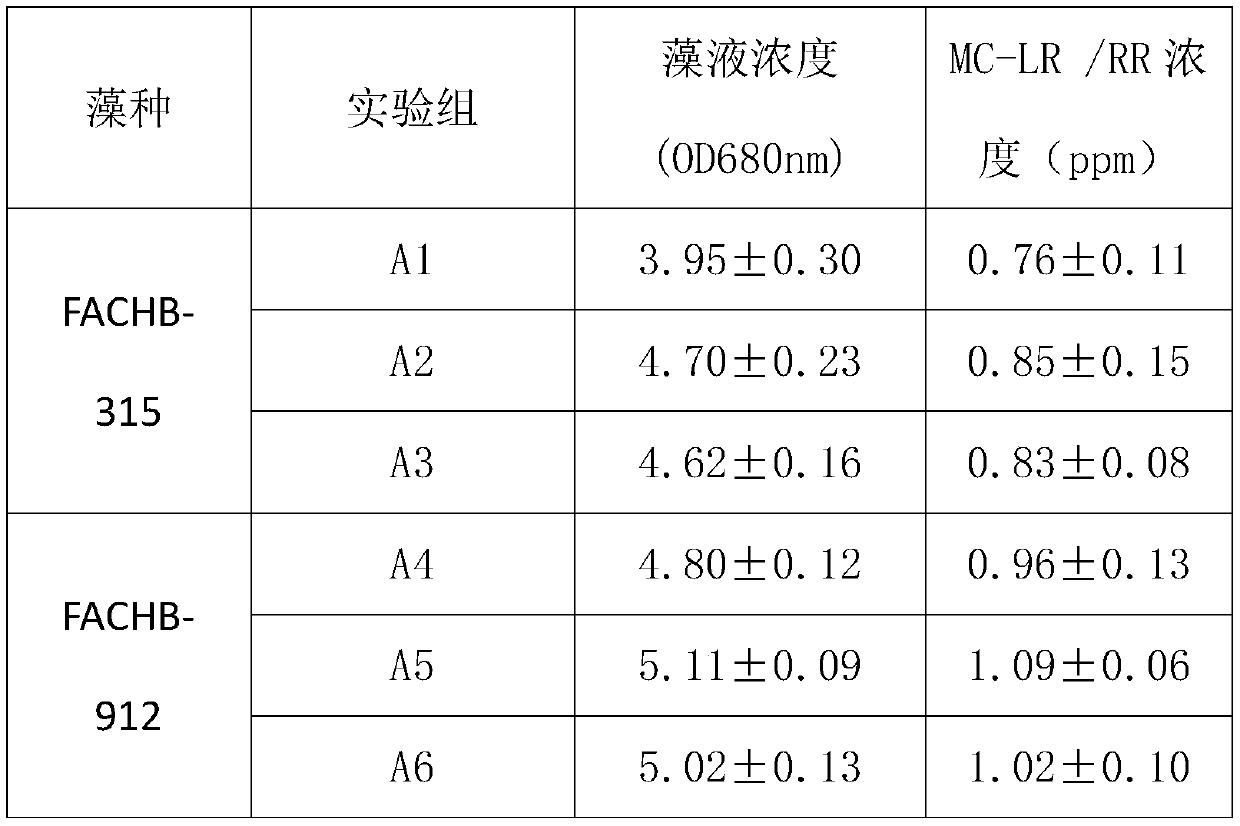

[0079] (1) Preliminary purification: The microcystin crude extract after three transfers (the original MC-LR / RR concentrations were 1.89±0.16ppm and 1.36±0.04ppm respectively) was subjected to vacuum rotary evaporation at 40°C , Preliminary purification was carried out through an adsorption column to obtain an initial pure liquid. In this example, D101 macroporous resin was selected as a filler to perform preliminary purification of the crude extract. The steps are as follows:

[0080] A. The pretreatment of adsorption column: the 100mm*1000mm chromatographic column that swells (95% ethanol) overnight 1000g macroporous adsorption resin is loaded into the bottom with 6 layers of gauze;

[0081] B. Rinse the column twice with 1000ml 95% ethanol;

[0082] C. Use 1000ml ddH 2 O rinse column 4 times;

[0083] D. Loading of algae toxin crude extract;

[0084] E. Elution steps: successively use 1000ml ddH 2 O was eluted twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com