Preparation method of N-acetylneuraminic acid dihydrate

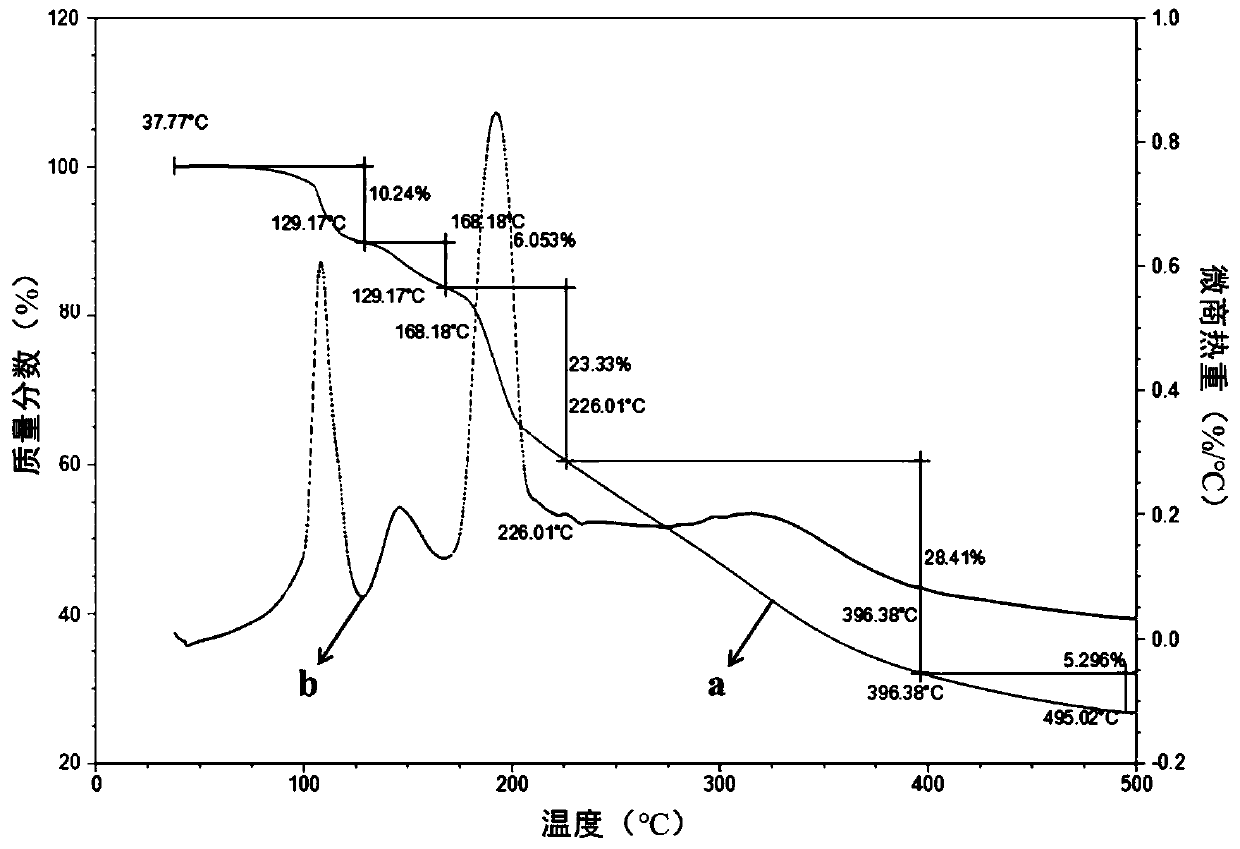

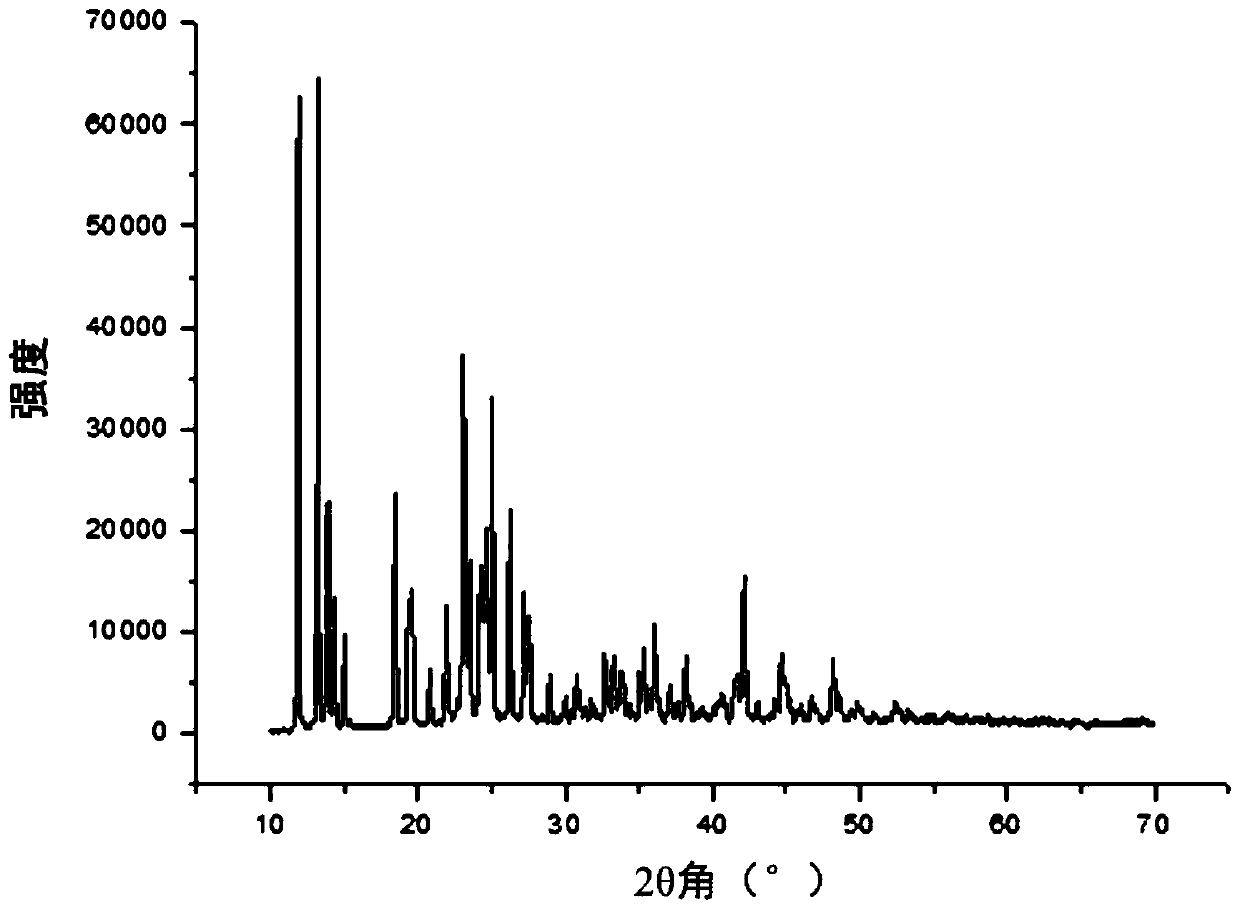

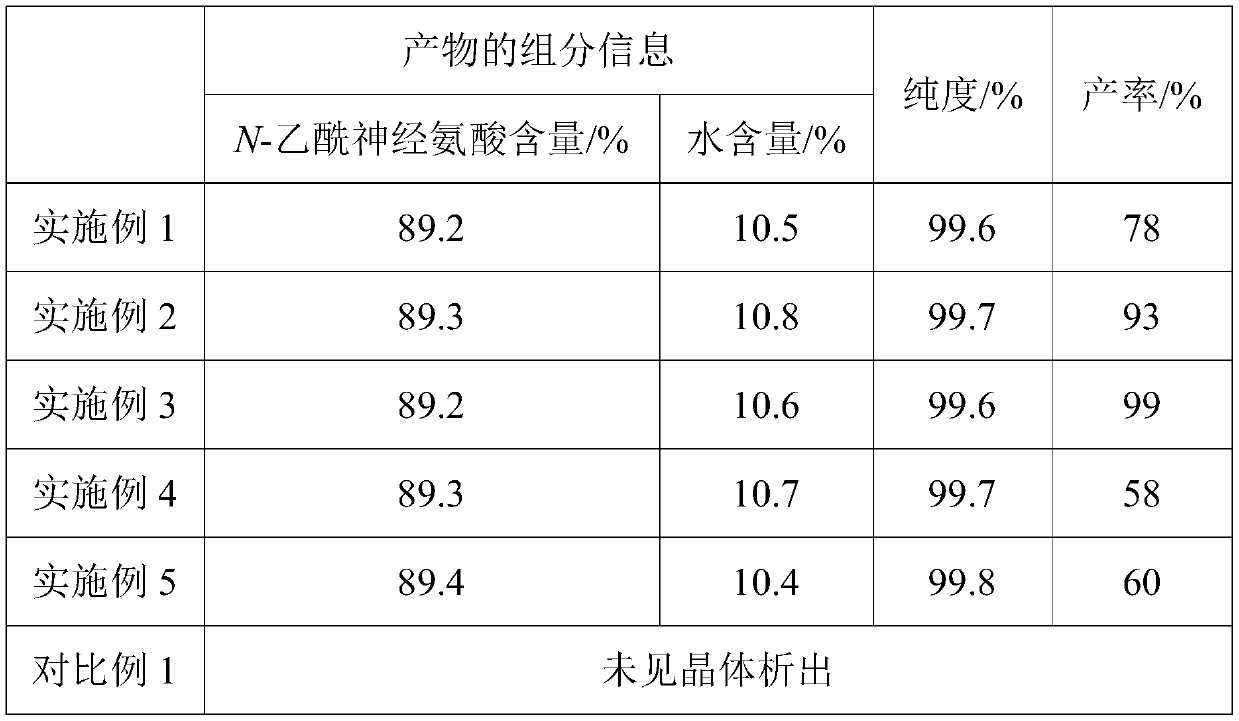

A technology of neuraminic acid dihydrate and acetylneuraminic acid, which is applied in the field of biochemistry, can solve the problems of strong corrosion of reaction equipment, low preparation efficiency, and slow crystallization speed on standing, and achieve high stability, mild conditions, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a preparation method of N-acetylneuraminic acid dihydrate, the specific steps are as follows:

[0049] (1) Mix 5g of N-acetylneuraminic acid with 100mL of pure water. After it is completely dissolved, add 0.2g of activated carbon to the aqueous solution of N-acetylneuraminic acid, and decolorize it in a constant temperature oscillating water bath at 30°C for 15 minutes. Then filter with a 0.22 μm filter membrane to collect the filtrate;

[0050] (2) Add 5 times the volume of acetonitrile to the filtrate obtained in step (1), let stand at 4°C for crystallization for 12 hours, then filter with a 0.22 μm filter membrane to collect the solid phase;

[0051] (3) The solid phase obtained in step (3) was washed with 75% aqueous ethanol, and then dried in an oven at 60° C. under normal pressure for 4 hours to obtain the N-acetylneuraminic acid dihydrate crystal.

Embodiment 2

[0053] This embodiment provides a preparation method of N-acetylneuraminic acid dihydrate, the specific steps are as follows:

[0054] (1) Mix 10g of N-acetylneuraminic acid with 100mL of pure water, and after it is completely dissolved, use a 0.22μm filter membrane to remove impurities and collect the filtrate;

[0055] (2) Add 7 times the volume of acetone to the filtrate obtained in step (1), let stand at 25°C for crystallization for 24 hours, then filter with a 0.22 μm filter membrane to collect the solid phase;

[0056] (3) The solid phase obtained in step (3) was washed with 75% ethanol aqueous solution, and then dried in a vacuum oven at 40° C. for 6 hours to obtain the N-acetylneuraminic acid dihydrate crystal.

Embodiment 3

[0058] This embodiment provides a preparation method of N-acetylneuraminic acid dihydrate, the specific steps are as follows:

[0059] (1) Mix 20g of N-acetylneuraminic acid with 100mL of pure water. After it is completely dissolved, add 0.3g of activated carbon to the aqueous solution of N-acetylneuraminic acid, and decolorize it in a constant temperature oscillating water bath at 40°C for 30 minutes. Then filter with a 0.22 μm filter membrane to collect the filtrate;

[0060] (2) Add 10 times the volume of crystallization hydration agent (equal volume mixture of acetonitrile and acetone) to the filtrate obtained in step (1), let stand at 10°C for crystallization for 18 hours, then filter with a 0.22 μm filter membrane to collect the solid phase;

[0061] (3) The solid phase obtained in step (3) was washed with 75% ethanol aqueous solution, and then dried in a vacuum oven at 50° C. for 3 hours to obtain the N-acetylneuraminic acid dihydrate crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com