SVC-prefabricated sturgeon product processing method based on sous vide cooking technology

A processing method and technology of meat products, which is applied in the field of food processing, can solve the problems of uneven salt content and long processing time of products, and achieve the effects of good water retention, stable quality and extended storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

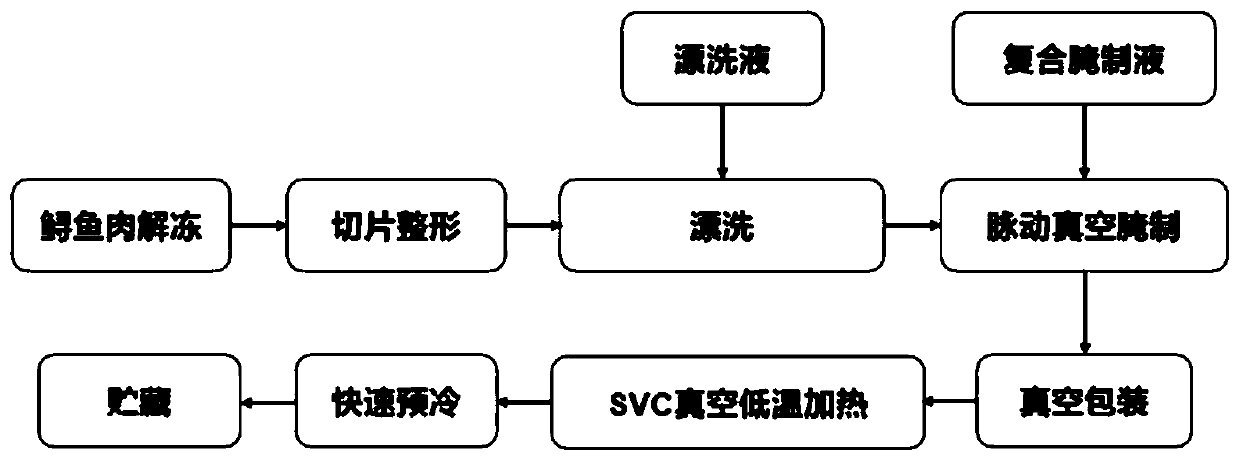

Method used

Image

Examples

Embodiment 1

[0060] 1) Thaw raw meat

[0061] Put the frozen sturgeon meat in a PE bag, heat-seal it under normal pressure, and then thaw it in a shower at a temperature of 20°C and a flow rate of 10m / min. The thawing time is 30 minutes. After thawing is complete, slices can be removed for shaping.

[0062] 2) Shaping and rinsing

[0063] Peel the thawed sturgeon meat and slice it. Each fillet is 5cm in length, 5cm in width and 2cm in thickness. Rinse the fish twice with 3 times the weight of rinsing solution, and the rinsing time is 8min each time. is 10°C. The formula of the rinsing liquid is: 0.2 g / 100 mL of sodium bicarbonate, 0.2 g / 100 mL of calcium chloride, 0.2 g / 100 mL of sodium citrate, and 1 g / 100 mL of carboxymethyl chitosan.

[0064] 3) Pulsating vacuum pickling

[0065] Add compound pickling liquid into the vacuum pot, and soak the fish fillets after shaping and rinsing according to the ratio of compound pickling liquid to fish meat of 1:3, set the temperature at 4°C, vacu...

Embodiment 2

[0081] 1) Thaw raw meat

[0082] Put the frozen sturgeon meat in a PE bag, heat-seal it under normal pressure, and then thaw it in a shower at a temperature of 25°C and a flow rate of 20m / min. The thawing time is 20 minutes. After thawing is complete, slices can be removed for shaping.

[0083] 2) Shaping and rinsing

[0084] Peel and slice the thawed sturgeon meat. Each fillet is 3cm in length, 3cm in width and 3cm in thickness. Rinse the fish twice with 4 times the weight of rinsing solution, each time for 5min, at a temperature of 4°C . The formula of the rinsing liquid is: sodium bicarbonate 0.4g / 100mL, calcium chloride 0.1g / 100mL, sodium citrate 0.1g / 100mL, carboxymethyl chitosan 2g / 100mL.

[0085] 3) Pulsating vacuum pickling

[0086] Add compound pickling liquid into the vacuum pot, and soak the fish fillets after shaping and rinsing according to the ratio of compound pickling liquid and fish meat to 1:4, set the temperature at 6°C, vacuum at -0.04MPa, and pulse Th...

Embodiment 3

[0102] 1) Thaw raw meat

[0103] Put the frozen sturgeon meat in a PE bag, heat-seal it under normal pressure, and then thaw it in a shower at a temperature of 22°C and a flow rate of 15m / min. The thawing time is 25 minutes. After thawing is complete, slices can be removed for shaping.

[0104] 2) Shaping and rinsing

[0105] Peel the thawed sturgeon meat, slice it, each fillet is 4cm in length, 4cm in width, and 2.5cm in thickness, rinse the fish twice with 3.5 times the weight of rinsing solution, each time for 7min, and the temperature is 6 ℃. The formula of the rinsing liquid is: sodium bicarbonate 0.3g / 100mL, calcium chloride 0.15g / 100mL, sodium citrate 0.15g / 100mL, carboxymethyl chitosan 1.5g / 100mL.

[0106] 3) Pulsating vacuum pickling

[0107] Add the compound pickling liquid into the vacuum pot, and soak the shaped fish fillets according to the ratio of the compound pickling liquid to the fish meat at a ratio of 1:3.5, set the temperature at 5°C, the vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com