Method for preparing perovskite thin film through low temperature quenching and application of perovskite thin film

A technology of perovskite and perovskite precursors, applied in the field of solar cells, can solve the problems of hindering the industrialization of perovskite cells, poor film uniformity, backwardness, etc., and achieve high photoelectric conversion efficiency and stability, high Absorption coefficient and carrier mobility, the effect of avoiding solvent turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a method for preparing a perovskite film by low-temperature quenching, comprising the following steps:

[0030] (1) Configure the perovskite precursor solution: MAI and PbI 2 Dissolve in DMSO solution according to the molar ratio of 1:1, the concentration is 1mol / L.

[0031] (2) Spin-coating method: pre-coat the perovskite precursor solution on a 2cm*2cm FTO substrate, and the spin-coating condition is 3000 rpm for 20 seconds.

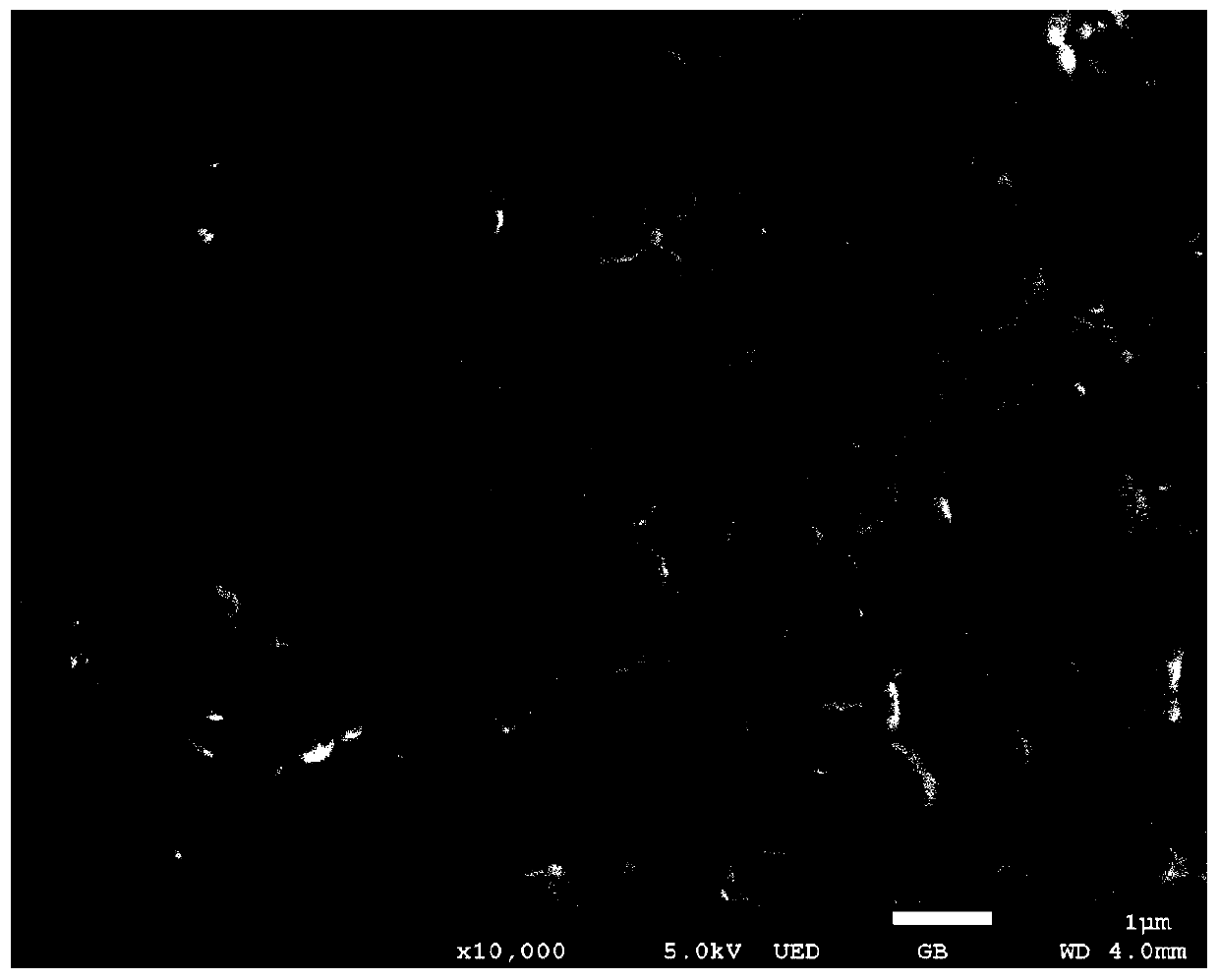

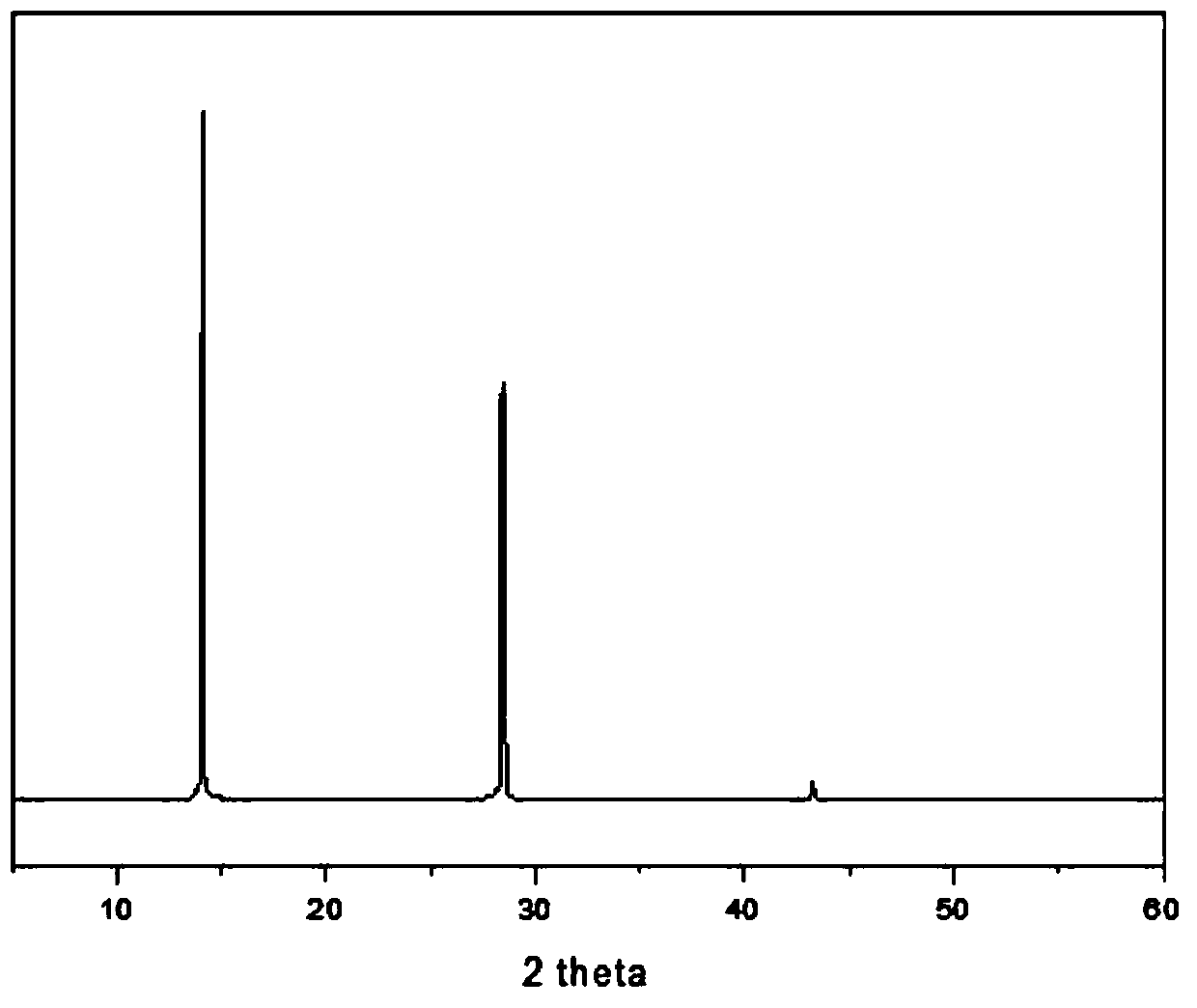

[0032] (3) The pre-coated perovskite wet film was immersed in liquid nitrogen for 30 seconds, and then taken out.

[0033] (4) In order to prevent condensation of water vapor, dry the quenched film with 0.5MPa nitrogen for 30 seconds.

[0034] (5) Put the dried film on a heating platform and anneal for 10 min at 100° C. to obtain a perovskite film.

[0035] (6) Spin-coat PCBM on the perovskite film, anneal for 10 minutes, then spin-coat BCP, and anneal for 10 minutes.

[0036] (7) Evaporate a metal Ag electrode on the ...

Embodiment 2

[0038] The invention provides a method for preparing a perovskite film by low-temperature quenching, comprising the following steps:

[0039] (1) Configure the perovskite precursor solution: FAI and PbI 2 Dissolve in DMF solution according to the molar ratio of 1:1, the concentration is 1.2mol / L.

[0040] (2) Scrape coating method: pre-coat the perovskite precursor solution on a 2cm*2cm FTO substrate, and the scrape coating conditions are 100um scraper height and 3mm / s speed.

[0041] (3) The pre-coated perovskite wet film was immersed in liquid helium for 30 seconds, and then taken out.

[0042] (4) In order to prevent condensation of water vapor, dry the quenched film with 0.5MPa argon for 30 seconds.

[0043] (5) Put the dried film on a heating platform and anneal for 30 minutes at 170° C. to obtain a perovskite film.

[0044] (6) Spin-coat PCBM on the perovskite film, anneal for 10 minutes, then spin-coat BCP, and anneal for 10 minutes.

[0045] (7) Evaporate a metal A...

Embodiment 3

[0047] The invention provides a method for preparing a perovskite film by low-temperature quenching, comprising the following steps:

[0048] (1) Configure the perovskite precursor solution: mix CsI and PbI 2 Dissolve in DMF solution according to the molar ratio of 1:1, the concentration is 1.2mol / L.

[0049] (2) Scrape coating method: pre-coat the perovskite precursor solution on a 2cm*2cm FTO substrate, and the scrape coating conditions are 100um scraper height and 3mm / s speed.

[0050] (3) The pre-coated perovskite wet film was immersed in liquid helium for 30 seconds, and then taken out.

[0051] (4) In order to prevent condensation of water vapor, dry the quenched film with 0.5MPa argon for 30 seconds.

[0052] (5) Put the dried film on a heating platform and anneal for 30 minutes at 170° C. to obtain a perovskite film.

[0053] (6) Spin-coat PCBM on the perovskite film, anneal for 10 minutes, then spin-coat BCP, and anneal for 10 minutes.

[0054] (7) Evaporate a met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com