Carbon fiber acoustic baffle applied to underwater detection equipment

An underwater detection equipment and carbon fiber technology, applied in the field of vibration reduction and noise reduction, can solve the problems of interfering with the normal operation of underwater acoustic detection equipment, insufficient strength of low-density foam materials, and heavy sound baffle plate, and improve the detection performance of the equipment. , excellent sound insulation performance, reducing the effect of vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

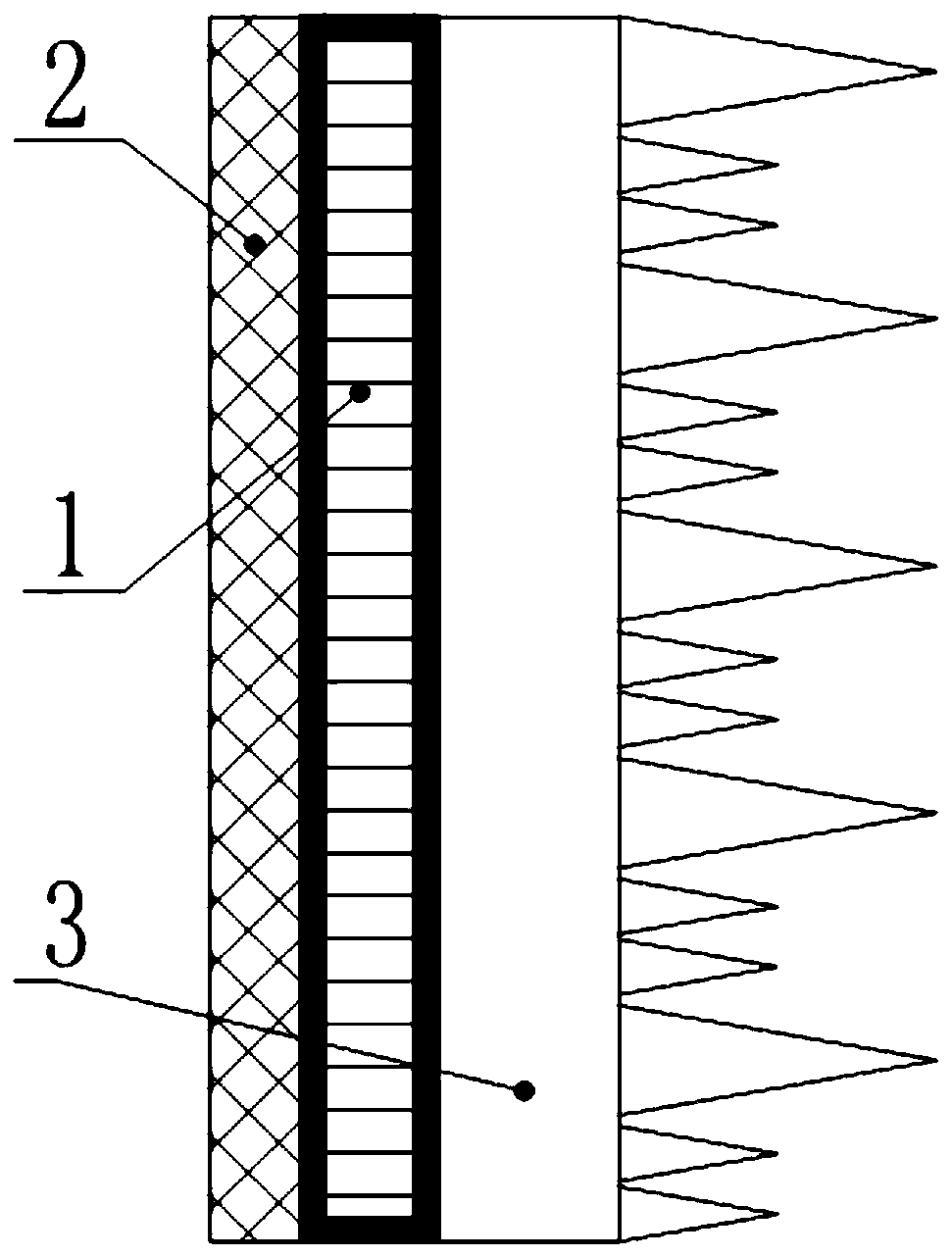

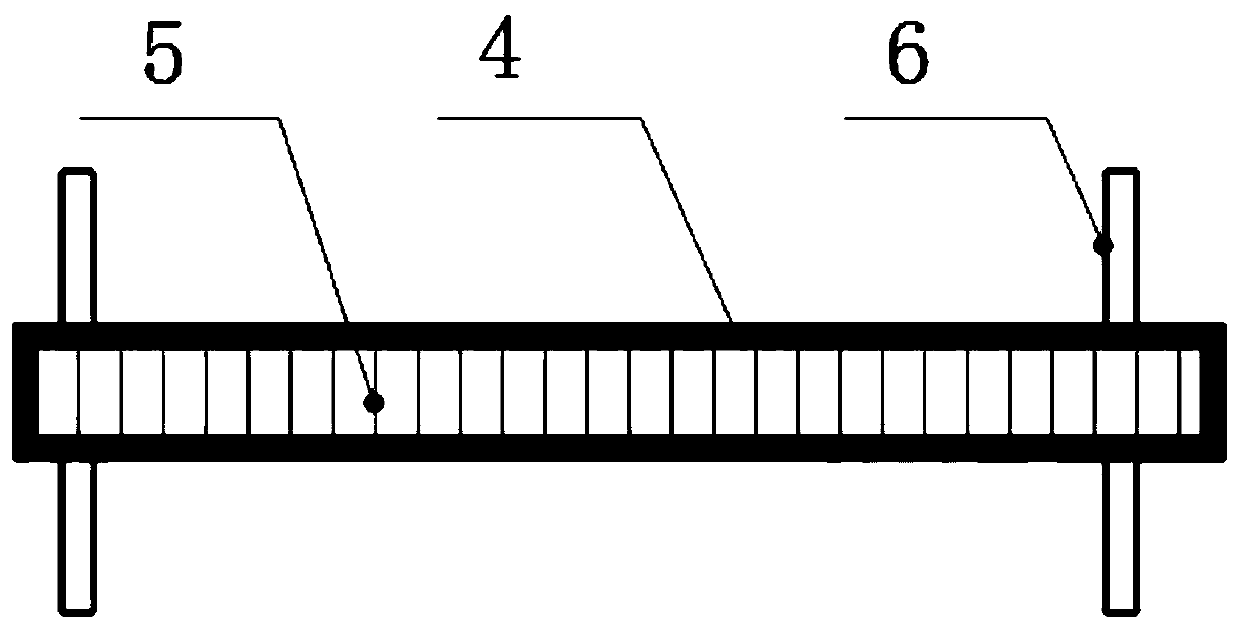

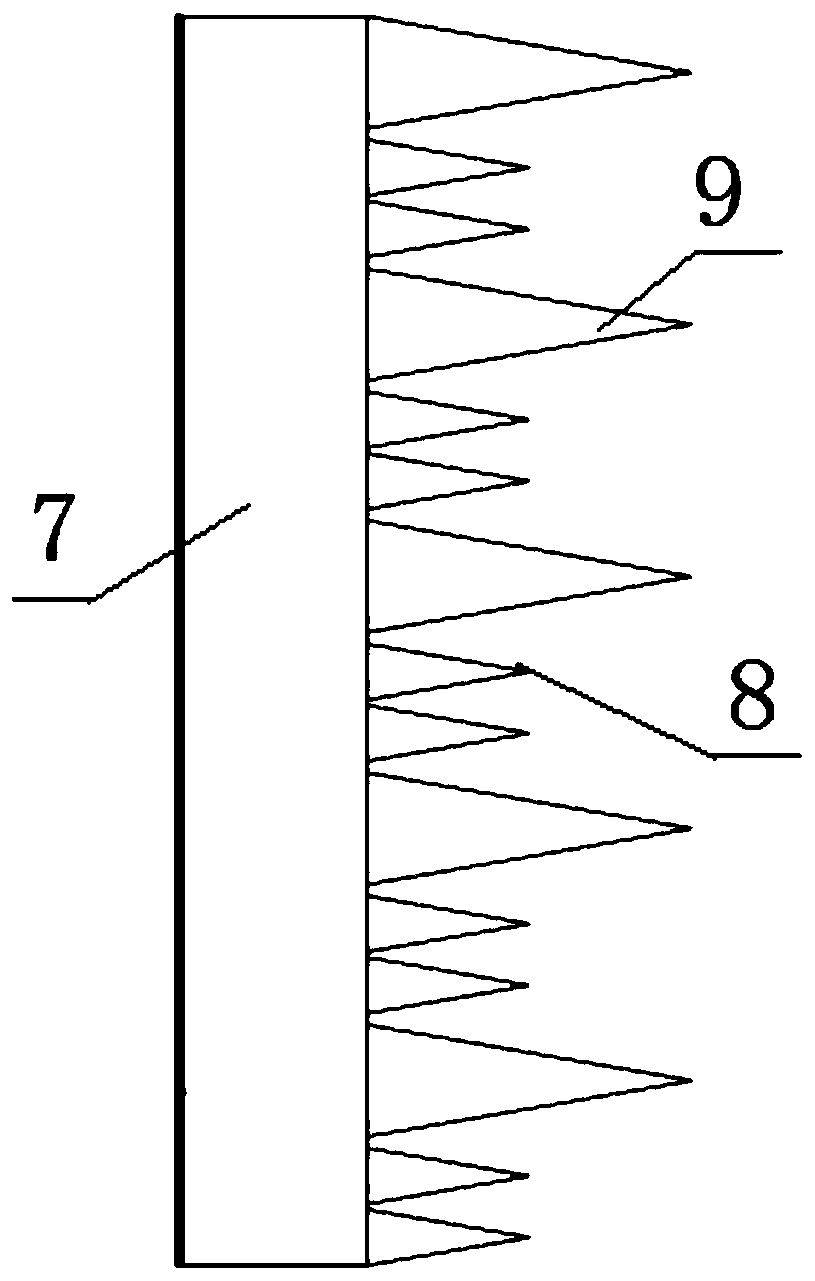

[0019] according to figure 1 , 2 , 3, this embodiment provides a carbon fiber acoustic baffle for underwater detection equipment, including a baffle main body 1, a damping layer 2 and a sound-absorbing layer 3, one side of the baffle main body 1 is tightly bonded A damping layer 2 is combined, and the other side of the baffle main body 1 is tightly bonded with a sound-absorbing layer 3. The baffle main body 1 adopts a structure in which an outer shell 4 wraps a carbon fiber honeycomb core material 5, and the carbon fiber honeycomb core material 5 and The outer casing 4 is composed of carbon fiber reinforced resin, the outer casing 4 and the carbon fiber honeycomb core material 5 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com