Warehouse hardened pavement and manufacturing method, hardened pavement based warehouse and mounting technology

A technology for warehouses and roadbeds, applied in the field of hardened pavement and production of warehouses, warehouses based on hardened pavements and installation processes, can solve problems such as being unsuitable for large warehouses and workshops, reduce plastering procedures, improve project quality, and resist water penetration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

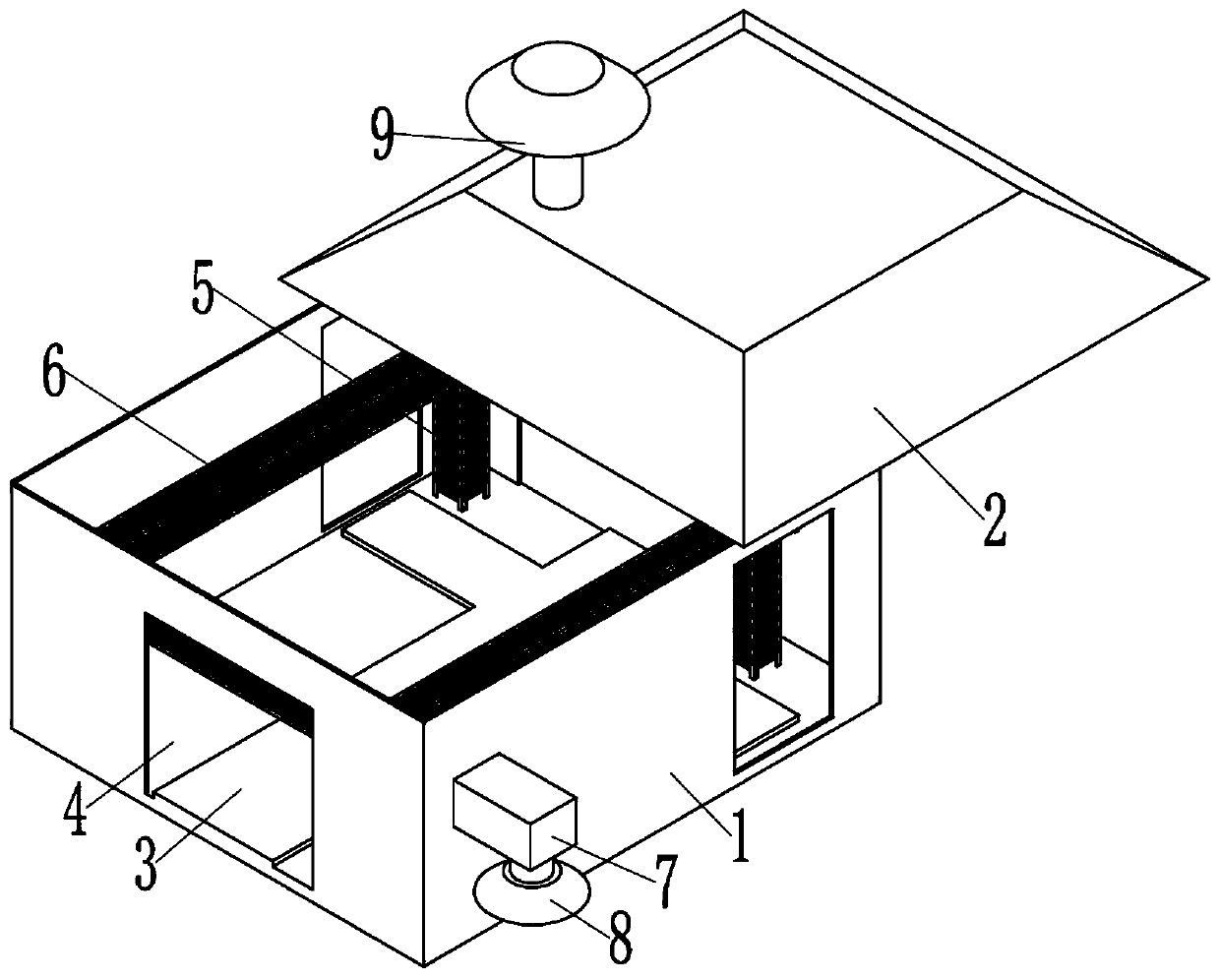

[0067] like Figure 1-8 As shown, the autoclaved lightweight sand-based aerated block member of this embodiment includes a composite column structure 5 installed in a dry warehouse;

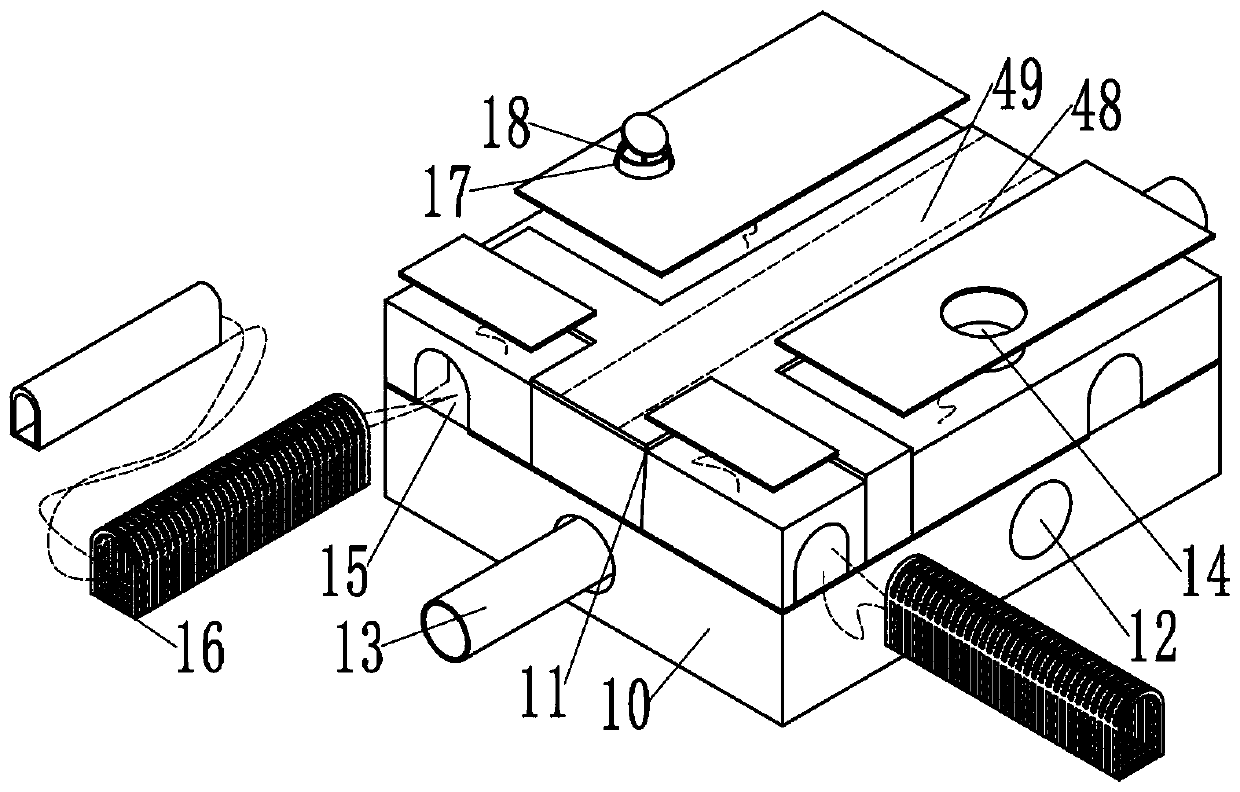

[0068] The composite column structure 5 includes a column support frame 32 vertically arranged, a column frame cutout hole 34 distributed on the column support frame 32, a column connecting frame 35 arranged between adjacent column support frames 32, and a column frame through the column frame cutout hole 34. The column side net plate 33 installed on the side wall of the column support frame 32, the column horizontal connecting frame 38 arranged at the upper end of the column support frame 32 and connected with the composite beam structure 6, and the column horizontal connecting frame 38 arranged at the lower end of the column support frame 32 and connected with the foundation The column bottom connecting frame 39, the column complex side wall 36 installed or pre-cast on the column support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com