Prefabricated block for bridge expansion joint and using method thereof

A technology of expansion joints and prefabricated blocks, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of vehicle jumping, unsatisfactory expansion joint flatness, loss of use function of expansion joints, etc., to achieve high flatness and avoid waste clogging Effect of expansion joints, good initial compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

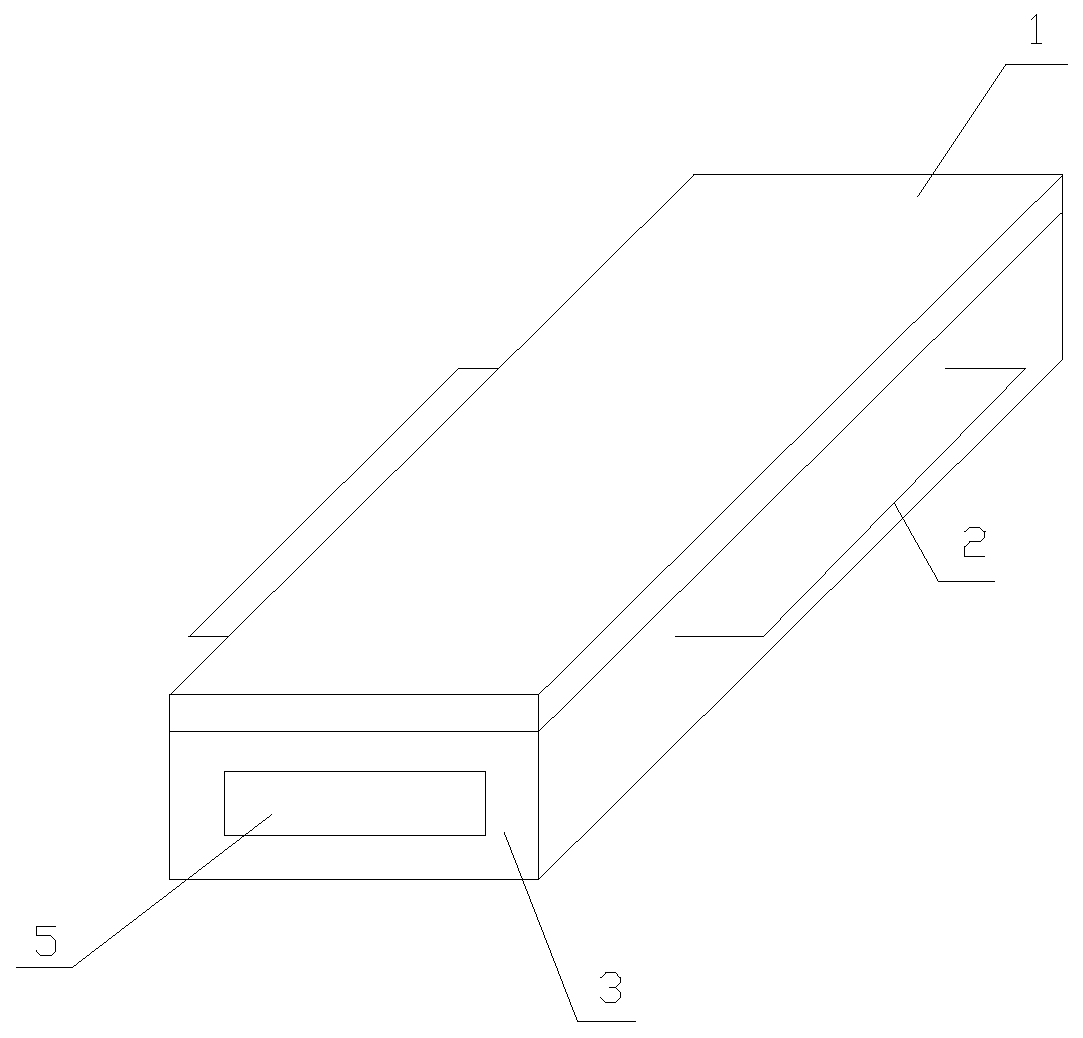

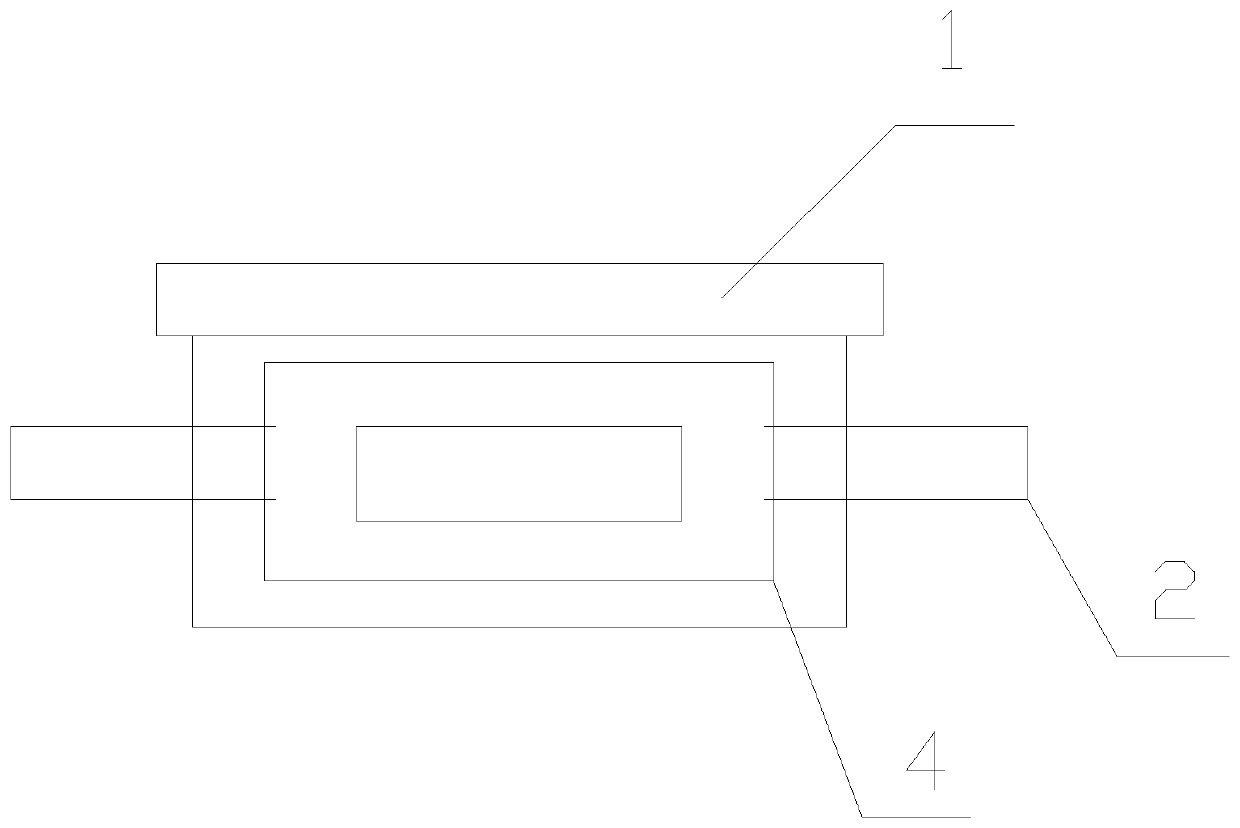

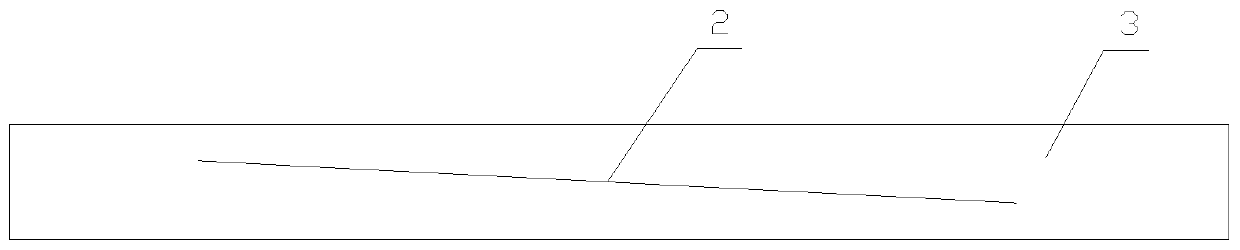

[0030] A prefabricated block for bridge expansion joints, comprising a steel plate 1, a hook 2 with a circular cross section, a prefabricated plate 3, a skeleton 4 and a socket 5, and the two sides of the prefabricated plate 3 are symmetrically provided with a hook 2, The frame 4 includes main ribs, vertical ribs and stirrups, the main ribs, vertical ribs and stirrups are fixedly connected to each other, the steel plate 1 is fixedly connected to the frame 4, the hook 2 is fixedly connected to the frame 4, and the socket 5 Located in the middle of the section of the prefabricated slab 3, one end of the hook 2 passes through the upper part of the side of the prefabricated slab 3, and the other end of the hook 2 passes through the lower part of the side of the prefabricated slab 3. The side of the plate 3 is an inclined structure, and the lower surface of the steel plate 1 coincides with the upper surface of the prefabricated plate 3 . The area of the lower surface of the steel...

Embodiment 2

[0033] The difference from Embodiment 1 is that the section of the hook 2 is rectangular.

Embodiment 3

[0035] A method for using prefabricated blocks for bridge expansion joints, comprising the following steps:

[0036] S1, the sliding shoe alignment method is used to pretreat the asphalt pavement, remove debris and other debris in the bridge expansion joint 6, and place the prefabricated slab 3 in the bridge expansion joint 6;

[0037] S2. Brush the release agent on the upper and lower surfaces of the steel plate 1 respectively;

[0038] S3, the connection between the prefabricated panels 3 is realized through the socket 5 by means of tenons, and the gaps in the direction of the road surface are filled with asphalt-impregnated wood panels;

[0039] S4. Place elevation piles at intervals of 10 meters within the length range of 30 meters on both sides of the bridge expansion joint 6, and pave the asphalt concrete surface layer by nailing piles. When passing through the expansion joint 6 of the bridge, the nail pile is laid out in advance; due to the rigid treatment method of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com