Arsenic removal nanofiber film with dual nanometer function core loads and preparing method thereof

A nanofiber membrane and nano-functional technology, which is applied in fiber treatment, textiles and papermaking, non-woven fabrics, etc., can solve the problems of low adsorption capacity and adsorption efficiency, insufficient structural strength, and low adsorption capacity, and achieve excellent chemical affinity, Effect of improving oxidation efficiency and improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

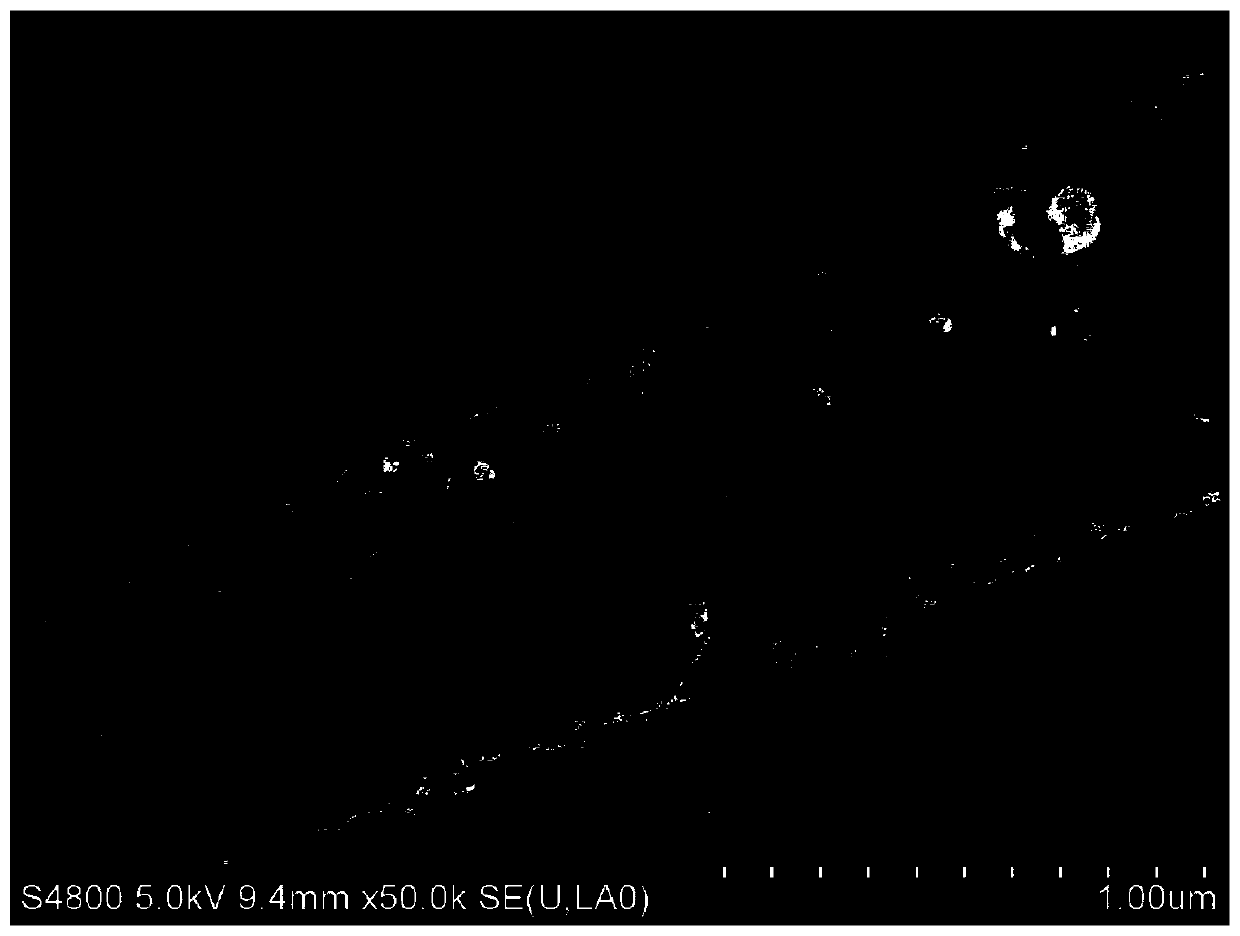

[0030] A preparation method for arsenic-removing nanofiber membrane loaded with double nanometer functional core, comprising the following steps:

[0031] (1) PAN is dissolved in the mixed solvent of DMF and acetone to obtain PAN solution, then La(NO 3 ) 3 ·6H 2 O is added in the PAN solution to obtain the electrospinning solution; wherein, the volume ratio of DMF and acetone in the mixed solvent is 3:1, the mass ratio of PAN and La element in the electrospinning solution is 10:1, and the PAN in the electrospinning solution The mass fraction of is 8wt%;

[0032] (2) Electrospinning the electrospinning solution obtained in step (1) through an electrospinning device to obtain an electrospun film; wherein, the parameters of the electrospinning are: the spinning voltage is 20kv, and the receiving distance is 20cm.

[0033] (3) Place the electrospun membrane obtained in step (2) in a dopamine hydrochloride solution with a dopamine concentration of 2 g / L, vibrate at a speed of 13...

Embodiment 2

[0038] A preparation method for arsenic-removing nanofiber membrane loaded with double nanometer functional core, comprising the following steps:

[0039] (1) PAN is dissolved in the mixed solvent of DMF and acetone to obtain PAN solution, then La(NO 3 ) 3 ·6H 2 O is added in the PAN solution to obtain the electrospinning solution; wherein, the volume ratio of DMF and acetone in the mixed solvent is 2:1, the mass ratio of PAN and La element in the electrospinning solution is 8:1, and the PAN in the electrospinning solution The mass fraction of is 6wt%;

[0040] (2) Electrospinning the electrospinning solution obtained in step (1) through an electrospinning device to obtain an electrospun membrane; wherein, the parameters of the electrospinning are: the spinning voltage is 15kv, and the receiving distance is 30cm.

[0041] (3) Place the electrospun membrane obtained in step (2) in a dopamine hydrochloride solution with a dopamine concentration of 3 g / L, vibrate at a speed of...

Embodiment 3

[0045] A preparation method for arsenic-removing nanofiber membrane loaded with double nanometer functional core, comprising the following steps:

[0046] (1) PAN is dissolved in the mixed solvent of DMF and acetone to obtain PAN solution, then La(NO 3 ) 3 ·6H 2 O is added in the PAN solution to obtain the electrospinning solution; wherein, the volume ratio of DMF and acetone in the mixed solvent is 4:1, the mass ratio of PAN and La element in the electrospinning solution is 15:1, and the PAN in the electrospinning solution The mass fraction of is 10wt%;

[0047] (2) Electrospinning the electrospinning solution obtained in step (1) through an electrospinning device to obtain an electrospun film; wherein, the parameters of the electrospinning are: the spinning voltage is 30kv, and the receiving distance is 15cm.

[0048] (3) Place the electrospun membrane obtained in step (2) in a dopamine hydrochloride solution with a dopamine concentration of 1 g / L, vibrate at a speed of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com