Composite luminescent fiber and preparation method and application thereof

A technology of luminescent fiber and composite fiber, which is applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component synthetic polymer rayon, etc., to achieve the effect of simple manufacturing process, full elasticity and high luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

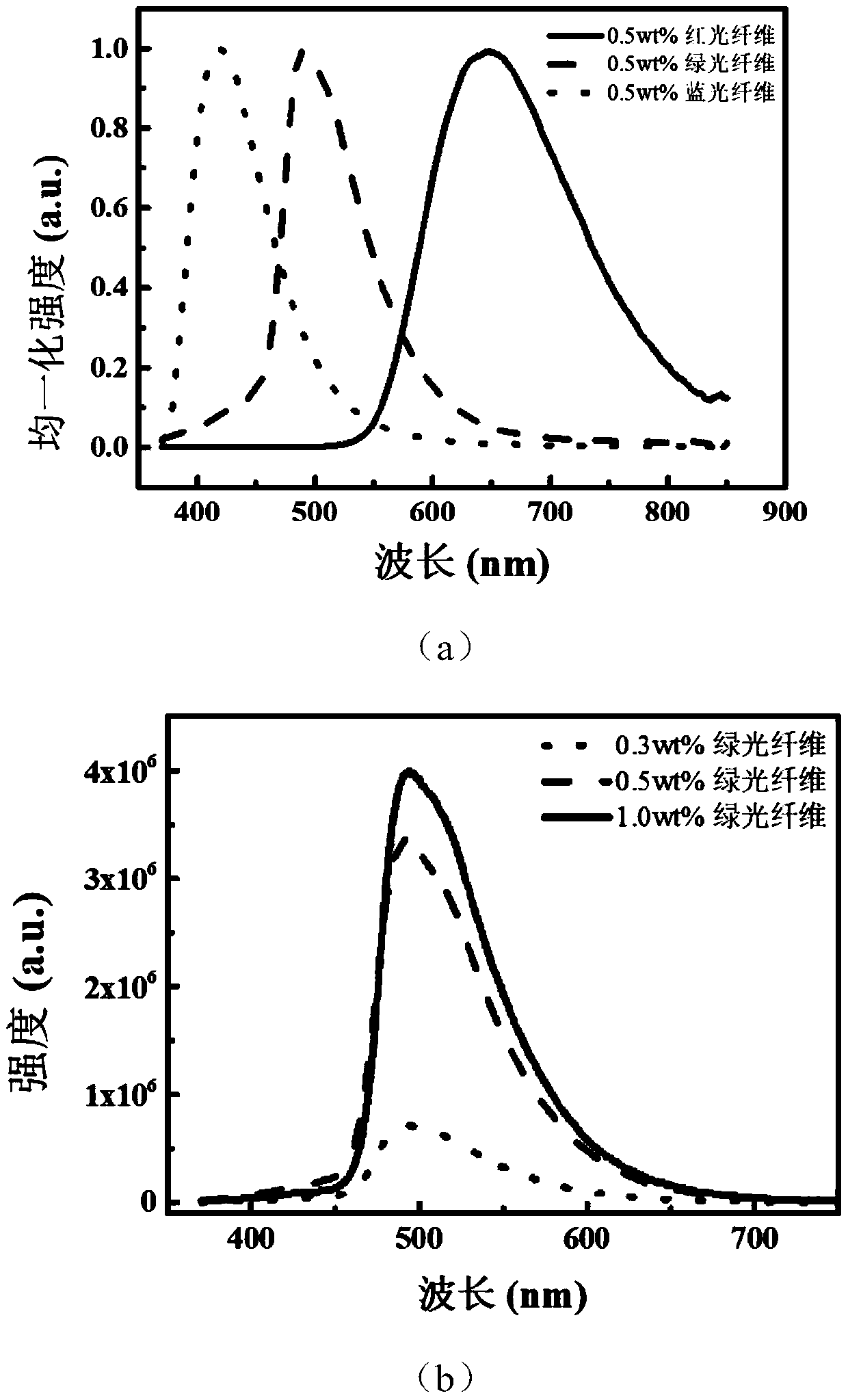

[0071] By adopting the preparation method provided by the invention, composite spinning of the polymer and aggregation-induced luminescent AIE molecules is realized, so as to prepare composite luminescent fibers. Since AIE molecules are highly luminescent under the excitation of ultraviolet light, and the polymer can provide the mechanical properties required for the composite fiber, the formed polymer / AIE composite luminescent fiber has excellent luminescence and mechanical properties that meet the requirements.

[0072] According to the present invention, the first solvent and the second solvent are each independently selected from at least one of methylene chloride, cyclohexane, phenol, toluene, acetonitrile, chlorobenzene and methyl acetate.

[0073] According to the present invention, in step 4), the conditions of the pre-curing treatment are: the pre-curing temperature is 40-80° C., and the pre-curing time is 5-40 min.

[0074] In the present invention, the pre-curing tr...

preparation example

[0119] use as figure 1 The spinning method shown to prepare luminescent fibers, the specific operation steps are:

[0120] Transfer the spinning solution into a 100ml syringe, and heat the oil bath temperature to 150°C at the same time. The syringe pump extrudes the spinning solution into the oil bath at a speed of 8ml / min., and the spinning solution solidifies rapidly in the oil bath. For fibers, the curing time is 8s, and then the fibers are collected on the winding shaft at a line speed of 2m / min., and finally washed and dried.

Embodiment 1

[0122] Step 1): Prepare aggregation-induced emission (AIE) molecule solution: add 0.006 g of aggregation-induced emission (AIE) molecule II into dichloromethane to obtain aggregation-induced emission (AIE) solution;

[0123] Step 2): Prepare AIE@PDMS component A compound solution: add 1.82g of PDMS component A to the aggregation-induced emission (AIE) molecular solution described in step 1), and stir manually to make it fully mixed and uniform ; Then put the prepared composite liquid into a vacuum drying oven at 40°C for 4 hours to be vacuum-dried;

[0124] Step 3): Prepare AIE@PDMS composite solution: add 0.18 g of PDMS component B to the composite solution described in step 2), stir well to make it evenly mixed, and obtain AIE@PDMS composite solution;

[0125] Step 4): Prepare AIE@PDMS spinning solution: put the AIE@PDMS composite solution described in step 3) into a 60°C oven and heat for 10 minutes, then cool for 30 minutes to form a spinning solution;

[0126] Step 5): P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com