Hot-melt adhesive sheet and production process thereof

A hot-melt film and production process technology, which can be used in heat-activated films/sheets, adhesives, films/sheets without carriers, etc., and can solve the problems of poor elasticity of hot-melt adhesives, inability to meet the comfort and aesthetics of shoes, and affecting the wearing of shoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

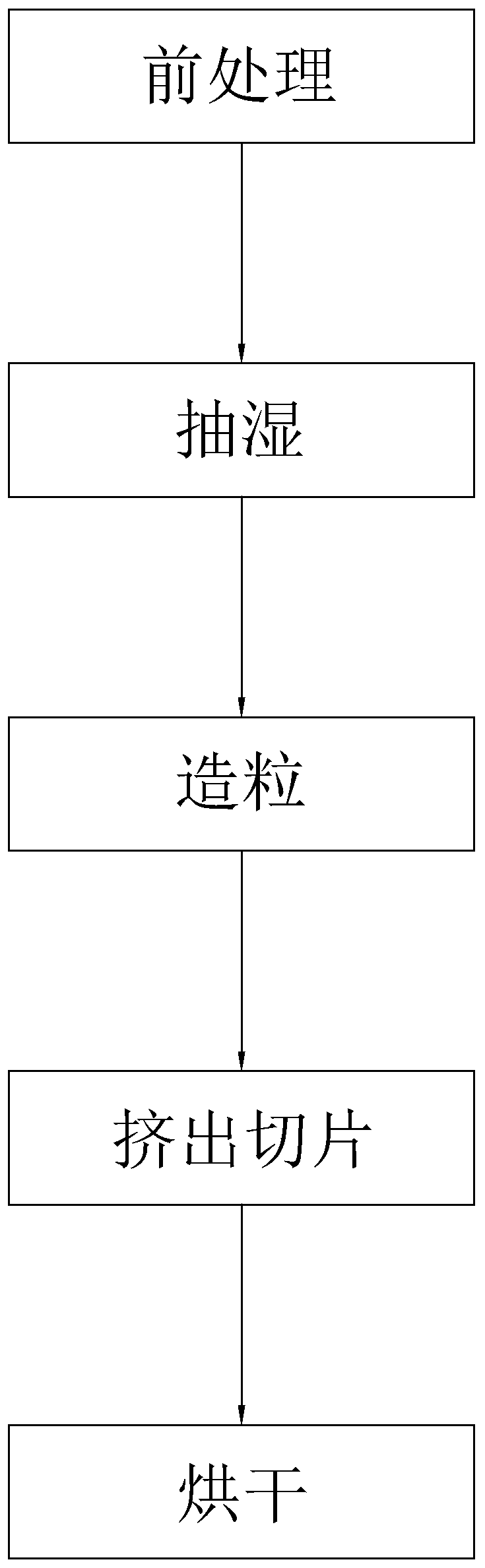

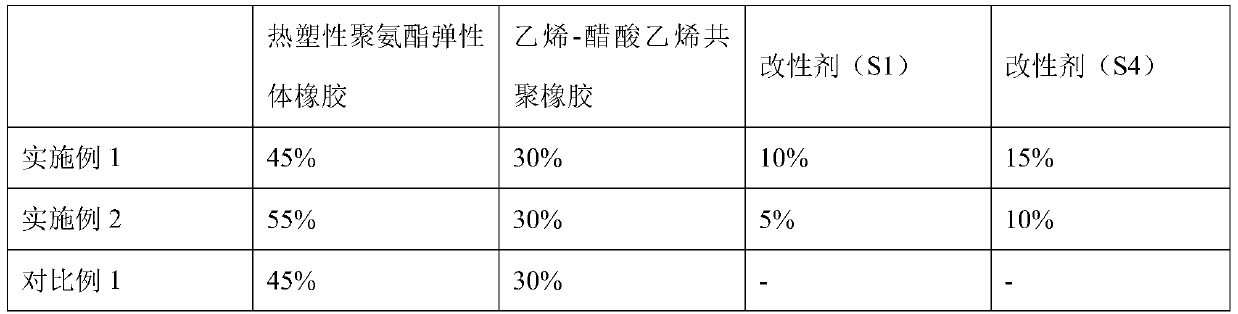

[0036] A production process of a hot-melt adhesive film, comprising the following steps:

[0037] S1. Pretreatment: Weigh the required components, add acrylic acid ethylene rubber copolymer to ethylene-vinyl acetate copolymer rubber, and use a high-speed mixer to pre-mix evenly for later use;

[0038] S2, dehumidification; transfer the material in S1 to the drying cylinder for dehumidification, the temperature is 45°C;

[0039] S3, granulation; adding the materials in S2 into a screw extrusion granulator, setting the temperature at 145°C, melt blending and extruding, the extruded mixture is cooled and granulated to obtain the primary product;

[0040] S4, extruding slices; mixing the initial product in S3 with thermoplastic polyurethane elastomer rubber and stirring evenly, then adding a certain amount of acrylic acid ethylene rubber copolymer, and transferring the material to the screw extrusion granulator after stirring evenly, The temperature is 145°C, melt blending and ex...

Embodiment 2

[0044] A production process of a hot-melt adhesive film, comprising the following steps:

[0045] S1. Pretreatment: Weigh the required components, add acrylic acid ethylene rubber copolymer to ethylene-vinyl acetate copolymer rubber, and use a high-speed mixer to pre-mix evenly for later use;

[0046] S2, dehumidification; transfer the material in S1 to the drying cylinder for dehumidification, the temperature is 55°C;

[0047] S3, granulation; adding the material in S2 into a screw extrusion granulator, setting the temperature at 165°C, melt blending and extruding, the extruded mixture is cooled and granulated to obtain the primary product;

[0048] S4, extruding slices; mixing the initial product in S3 with thermoplastic polyurethane elastomer rubber and stirring evenly, then adding a certain amount of acrylic acid ethylene rubber copolymer, and transferring the material to the screw extrusion granulator after stirring evenly, The temperature is 165°C, melt blending and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com