Preparation method and application of silicone rubber film with underwater self-healing capability and adhesiveness

A silicone rubber film, self-healing technology, applied in the direction of film/sheet, adhesive, adhesive type, etc. without carrier, can solve the problems of non-existence of self-healing, limited application, etc., and achieve extended service life and excellent mechanical properties , the effect of high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

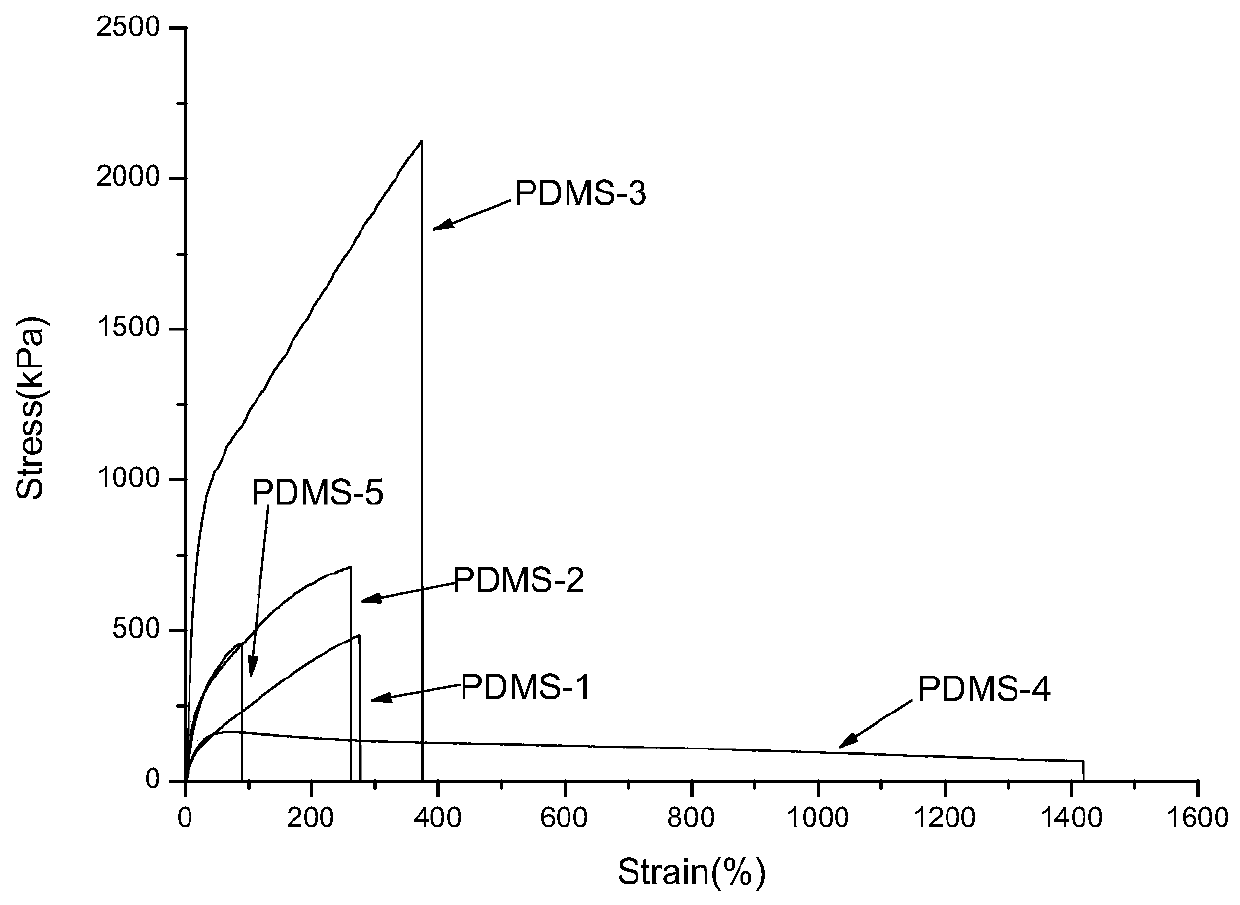

Embodiment 1

[0036] Get 5g bis(3-aminopropyl) end-capped poly(dimethylsiloxane) (H 2 N-PDMS-NH 2 ), 0.23g of 4,4'-diaminodiphenyl disulfide (APD) and 0.25g of terephthalaldehyde (TPA) were dissolved in 25mL of chlorobenzene, and the solution was fully stirred at room temperature for 25min. After it was completely dissolved, the A chlorobenzene solution of 0.51 g of isophorone diisocyanate and 0.07 g of tris(2-aminoethyl)amine (both at a concentration of 0.1 g / ml) was slowly dropped into the above mixed solution respectively. After stirring at 60°C for 3 hours, pour the mixed solution into a polytetrafluoroethylene mold with a length of 10cm, a width of 10cm, and a height of 5mm, dry at 60°C for 12 hours, and then increase the temperature to 80°C for 12 hours to obtain the silicone rubber The thickness of the thin film (PDMS-1) is about 1 mm, and it is taken out and stored in a petri dish.

Embodiment 2

[0038] Get 7g bis(3-aminopropyl) end-capped poly(dimethylsiloxane) (H 2 N-PDMS-NH 2 ), 0.32g of 4,4'-diaminodiphenyl disulfide (APD) and 0.35g of terephthalaldehyde (TPA) were dissolved in 30mL of chlorobenzene, and the solution was fully stirred at room temperature for 20min. After it was completely dissolved, the 0.72 g of isophorone diisocyanate and 0.19 g of tris(2-aminoethyl)amine in chlorobenzene (concentrations both 0.1 g / ml) were slowly dropped into the above mixed solution respectively. After reacting at 60°C for 3 hours, pour the mixed solution into a polytetrafluoroethylene mold with a length of 10cm, a width of 10cm, and a height of 5mm, and dry it at 60°C for 24 hours. The thickness of the obtained silicone rubber film (PDMS-2) is about 1.5mm , Take it out and store it in a petri dish.

Embodiment 3

[0040] Get 5g bis(3-aminopropyl) end-capped poly(dimethylsiloxane) (H 2 N-PDMS-NH 2 ) and 0.23g of 4,4'-diaminodiphenyl disulfide (APD) were dissolved in 25mL of chlorobenzene, the solution was fully stirred at room temperature for 30min, after complete dissolution, 0.93g of isophorone diisocyanate and a chlorobenzene solution of 0.07 g of tris(2-aminoethyl)amine (concentration: 0.1 g / ml) were slowly dropped into the above mixed solution respectively. After reacting at 60°C for 2.5h, pour the mixed solution into a polytetrafluoroethylene mold with a length of 7cm, a width of 7cm, and a height of 5mm, and dry it at 70°C for 24 hours. The thickness of the obtained silicone rubber film (PDMS-3) is about 1mm. And it is relatively transparent, and it is preserved with polypropylene film after taking it out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com