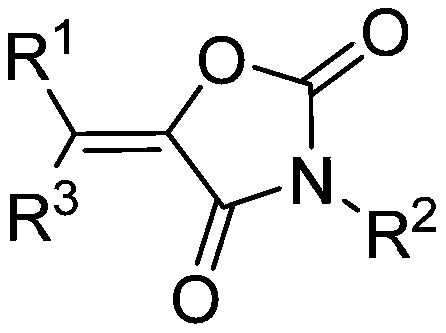

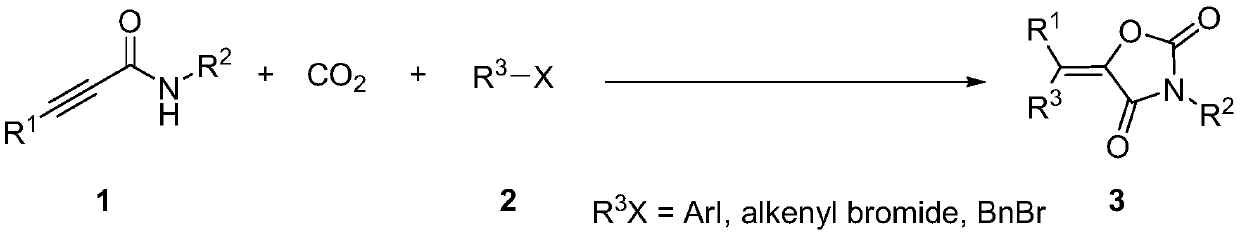

Method for producing tetra-substituted vinyl 2,4-oxazolidinedione from carbon dioxide

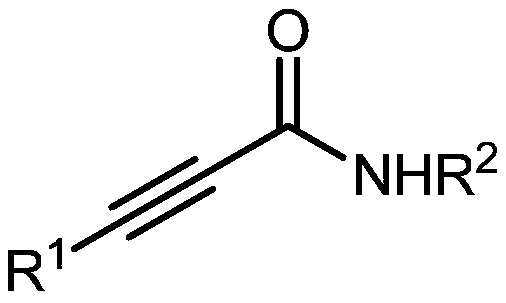

A technology of vinyl oxazolidine and carbon dioxide, which is applied in the field of preparation of tetrasubstituted vinyl oxazolidine-2,4-dione, and functionalization reaction, which can solve the problems of expensive and difficult-to-obtain substrates, and achieve the extension of product types , mild reaction conditions and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of 3-benzyl-5-(dibenzylidene)oxazolidine-2,4-dione

[0026] [3-benzyl-5-(diphenylmethylene)oxazolidine-2,4-dione]

[0027]

[0028] In the dried Schlenk tube, add in sequence: N-benzyl-3-phenylpropanamide (0.2mmol, 47mg), potassium carbonate (0.4mmol, 55.2mg), iodobenzene (0.24mmol, 49mg) , bistriphenylphosphine palladium dichloride (0.02mmol, 14mg), cuprous iodide (0.03mmol, 6mg), dimethyl sulfoxide 2mL, with CO 2 Replace the gas in the reaction tube three times, and finally fill the reaction tube with 0.1MPa CO 2 , and the above-mentioned Schlenk tube was placed at ambient temperature and stirred for 24 h. The reaction was terminated, and the reaction solution was quenched with 2 mL of saturated brine, extracted several times with ethyl acetate (4 mL×5), the organic phases were combined, and the solvent was removed on a rotary evaporator. Finally, it was separated by silica gel column chromatography (eluent: ethyl acetate: petroleum ether ...

Embodiment 2

[0030] Example 2: Preparation of 3-benzyl-5-(dibenzylidene)oxazolidine-2,4-dione

[0031] [3-benzyl-5-(diphenylmethylene)oxazolidine-2,4-dione]

[0032]

[0033] In the dried Schlenk tube, add in sequence: N-benzyl-3-phenylpropanamide (0.2mmol, 47mg), potassium carbonate (0.4mmol, 55.2mg), iodobenzene (0.24mmol, 49mg) , bistriphenylphosphine palladium dichloride (0.01mmol, 7mg), cuprous iodide (0.06mmol, 6mg), dimethyl sulfoxide 2mL, with CO 2 Replace the gas in the reaction tube three times, and finally fill the reaction tube with 0.1MPa CO 2 , and the above-mentioned Schlenk tube was placed at ambient temperature and stirred for 24 h. The reaction was terminated, and the reaction solution was quenched with 2 mL of saturated brine, extracted several times with ethyl acetate (4 mL×5), the organic phases were combined, and the solvent was removed on a rotary evaporator. Finally, it was separated by silica gel column chromatography (eluent: ethyl acetate: petroleum ether =...

Embodiment 3

[0034] Example 3: Preparation of 3-benzyl-5-(dibenzylidene)oxazolidine-2,4-dione

[0035] [3-benzyl-5-(diphenylmethylene)oxazolidine-2,4-dione]

[0036]

[0037] In the dried Schlenk tube, add in sequence: N-benzyl-3-phenylpropanamide (0.2mmol, 47mg), potassium carbonate (0.4mmol, 55.2mg), iodobenzene (0.24mmol, 49mg) , bistriphenylphosphine palladium dichloride (0.015mmol, 10.5mg), cuprous iodide (0.05mmol, 9.5mg), dimethyl sulfoxide 2mL, with CO 2 Replace the gas in the reaction tube three times, and finally fill the reaction tube with 0.1MPa CO 2 , and the above-mentioned Schlenk tube was placed at ambient temperature and stirred for 24 h. The reaction was terminated, and the reaction solution was quenched with 2 mL of saturated brine, extracted several times with ethyl acetate (4 mL×5), the organic phases were combined, and the solvent was removed on a rotary evaporator. Finally, it was separated by silica gel column chromatography (eluent: ethyl acetate: petroleum e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com